-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

dec . 03, 2024 12:10 Back to list

blind flange manufacturers

Understanding Blind Flange Manufacturers

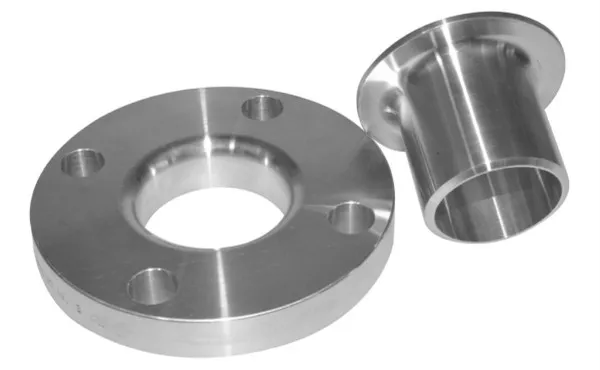

When it comes to piping systems, flanges are crucial components that provide points for connection and disconnection between pipes, valves, and other equipment. One type of flange that plays a vital role in various industrial applications is the blind flange. Blind flanges are solid disks with no central hole, designed to seal the end of a piping system, preventing the flow of fluids and gases. The choice of a reliable blind flange manufacturer can significantly affect the performance and reliability of your piping system.

What Are Blind Flanges?

Blind flanges are circular plates with no bore, used to terminate the ends of a pipeline. These flanges are commonly employed in systems where a temporary or permanent closure is required. They are vital in ensuring that the system remains pressurized and protected from external contaminants. Blind flanges are manufactured in various materials, including carbon steel, stainless steel, and alloy materials, making them suitable for different applications and environmental conditions.

Selecting a Blind Flange Manufacturer

When it comes to sourcing blind flanges, selecting a reputable manufacturer is essential. Several factors should be considered to ensure that you are choosing a supplier that can meet your needs effectively.

1. Quality Assurance A reliable manufacturer should adhere to strict quality control processes. Look for compliance with industry standards such as ANSI, ASME, and ASTM. Certifications like ISO 9001 can be indicators of a manufacturer’s commitment to quality.

2. Material Options Different applications require different materials. A good manufacturer should offer a range of materials and have the capability to provide flanges tailored to specific environmental conditions, such as high temperature or corrosive environments.

blind flange manufacturers

3. Customization In many cases, standard sizes may not fit your specific applications. Choose a manufacturer that can provide custom solutions, ensuring that the blind flanges meet all technical specifications.

4. Experience and Reputation Consider the experience of the manufacturer in the industry. Established manufacturers with a good reputation are more likely to provide products that meet high standards, backed by customer reviews and testimonials.

5. Lead Times and Support In today’s fast-paced industrial environment, timely delivery is crucial. Verify the manufacturer's lead times and their ability to provide technical support and customer service throughout the procurement process.

The Importance of Testing and Inspection

Before flanges are delivered to clients, they should undergo rigorous testing and inspection. This ensures that they can withstand the pressure and temperature conditions they will face in the field. Common testing methods include hydrostatic testing, ultrasonic testing, and visual inspections. High-quality manufacturers will ensure that their blind flanges not only meet but exceed industry standards.

Conclusion

In summary, blind flanges are essential components in maintaining the integrity of piping systems. Choosing the right blind flange manufacturer is vital for ensuring quality, reliability, and performance. Various factors should be considered when selecting a manufacturer, including quality assurance, material options, customization capabilities, experience, and support. By taking the time to partner with a reputable supplier, industries can ensure the longevity and efficiency of their systems—a critical aspect of operational success. As the demand for high-quality piping solutions continues to rise, investing in superior blind flanges from established manufacturers will undoubtedly pay off in the long run.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024

-

DIN2605-2617 Butt-Welding Fittings LR/SR 45°/90°/180° Seamless/Weld

NewsApr.23,2024