-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

Nov . 24, 2024 02:49 Back to list

High-Quality 316L Seamless Pipe for Corrosion Resistance and Durability

The Versatility and Applications of 316L Seamless Pipe

316L seamless pipe is a widely used material in various industries due to its excellent mechanical properties, corrosion resistance, and versatility. This non-magnetic, austenitic stainless steel grade is particularly known for its low carbon content, which enhances its resistance to sensitization during welding processes. This article explores the key features, benefits, and applications of 316L seamless pipe.

Composition and Properties

316L stainless steel is composed of iron, chromium, nickel, and molybdenum, giving it superior toughness and resistance to oxidation and pitting corrosion, especially in chloride environments. The typical composition includes about 16% chromium, 10% nickel, and 2% molybdenum. The lower carbon content (below 0.03%) minimizes the risk of carbide precipitation during welding, making 316L ideal for applications that require welding near sensitive areas.

The seamless manufacturing process involves creating pipes without any seams or welds, which enhances their strength and integrity. This seamless construction offers better pressure handling capabilities, making 316L seamless pipes suitable for high-pressure applications. Additionally, they exhibit excellent ductility, making it easier to fabricate into various shapes and sizes.

Corrosion Resistance

One of the most significant advantages of 316L seamless pipe is its exceptional resistance to corrosion. It can withstand harsh environments where exposure to chemicals, saltwater, and acidic conditions is prevalent. This property makes it indispensable in industries such as pharmaceuticals, food and beverage, and chemical processing. The presence of molybdenum in its composition provides enhanced resistance to pitting and crevice corrosion, which are common in environments with halides.

Applications

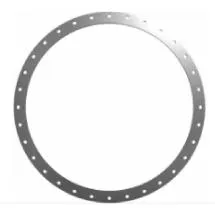

316l seamless pipe

Due to its remarkable properties, 316L seamless pipe finds application across a range of industries. Here are some notable examples

1. Chemical Processing In chemical manufacturing plants, 316L seamless pipes are used for transporting corrosive substances. Their ability to withstand extreme environments ensures system integrity and safety.

2. Marine Applications The marine industry frequently employs 316L seamless pipes for boat fittings, railings, and other components exposed to saltwater. Their corrosion resistance is critical for maintaining longevity and durability in these applications.

3. Oil and Gas Within the oil and gas sector, 316L seamless pipes are used in pipelines and upstream operations, where exposure to corrosive environments is inevitable. Their strength and resistance to high pressures make them suitable for such demanding applications.

4. Pharmaceutical and Food Processing In these industries, the hygienic requirements are paramount. 316L seamless pipes are easy to clean and sterilize, ensuring compliance with strict sanitary standards. Their non-reactive nature also prevents contamination of the products being transported.

5. Power Generation 316L seamless pipes are utilized in power plants, particularly in superheating and heat exchangers, due to their ability to endure high temperatures and pressures.

Conclusion

316L seamless pipe is an exceptional material that combines strength, corrosion resistance, and versatility. Its unique properties make it suitable for a wide range of applications across various industries, from chemical processing to marine environments. As industries continue to advance and seek materials that can withstand harsh conditions, the demand for 316L seamless pipes is expected to grow. This stainless steel grade represents an optimal solution, proving its reliability in critical applications where performance and safety are non-negotiable. Whether it’s enhancing productivity in manufacturing processes or ensuring safety in infrastructure, 316L seamless pipes stand out as a superior choice in the realm of industrial materials.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024

-

DIN2605-2617 Butt-Welding Fittings LR/SR 45°/90°/180° Seamless/Weld

NewsApr.23,2024