-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

Nov . 13, 2024 11:34 Back to list

blank flange plate

Understanding Blank Flange Plates A Key Component in Engineering

Blank flange plates, often referred to simply as blind flanges, are essential components in piping and engineering systems. These flanges play a crucial role in the assembly and maintenance of pipelines, holding the system together while preventing the escape of fluids or gasses. Their unique design and functional application make them an indispensable part of many industrial processes.

What is a Blank Flange Plate?

A blank flange plate is a flat disc, usually crafted from metal or other durable materials, that has no central opening. This characteristic distinguishes it from other types of flanges that are designed to connect two sections of piping. The primary function of a blank flange is to seal off a pipe end, effectively blocking the flow of fluids or gases. This can be particularly useful during maintenance or when sections of a system are being altered or inspected.

Applications of Blank Flange Plates

Blank flange plates find a wide variety of applications across different industries. In the oil and gas sector, for instance, they are used to cap off pipelines that may require temporary isolation for repairing or upgrading. In water treatment facilities, these flanges are essential for ensuring that pipelines can be securely closed during maintenance operations. Additionally, in the manufacturing industry, blank flanges may be used in vessels and tanks where closures are necessary.

The versatility of blank flange plates is further highlighted by the fact that they can be customized to meet specific requirements. Various materials can be used, including stainless steel, carbon steel, plastic, and even brass, depending on the environmental conditions and the substances being transported through the piping system. Factors such as pressure, temperature, and the chemical nature of the contents must be considered when selecting an appropriate blank flange.

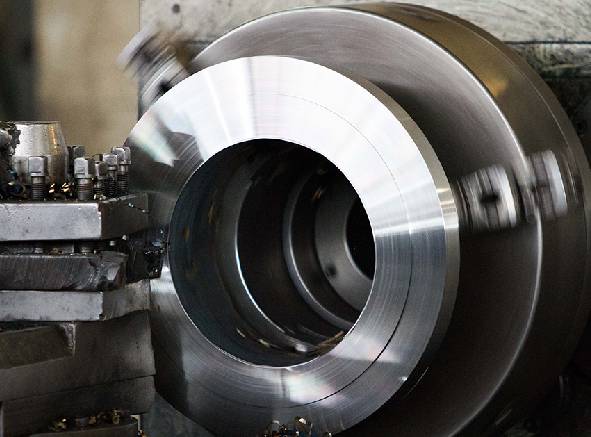

blank flange plate

Advantages of Using Blank Flange Plates

One of the key advantages of blank flange plates is their ability to provide a secure barrier in a piping system, allowing for safe maintenance operations. By using a blind flange to seal off a section of pipe, workers can prevent leaks and spills, significantly enhancing safety in the workplace.

Moreover, the installation and removal of blank flange plates are straightforward and efficient. This ease of use saves valuable time during maintenance operations, making it possible for engineers and technicians to complete tasks more effectively and with minimal disruptions to the overall process.

Standards and Specifications

When working with blank flange plates, it is important to adhere to relevant industry standards and specifications. Organizations like the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) provide guidelines that govern the dimensions, materials, and pressure ratings of flanges. Compliance with these standards ensures reliability, compatibility, and safety in engineering applications.

Conclusion

In conclusion, blank flange plates are a vital component in the world of engineering and piping systems. Their ability to permanently or temporarily seal pipe ends provides critical support for safe operation and maintenance of various industrial applications. With their customizable features and adherence to industry standards, blank flanges represent a reliable and efficient solution for managing the flow of fluids and gases in diverse settings. Whether in oil and gas, water treatment, or manufacturing, understanding the significance of these components is essential for anyone involved in engineering and industrial operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024

-

DIN2605-2617 Butt-Welding Fittings LR/SR 45°/90°/180° Seamless/Weld

NewsApr.23,2024