-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

Dec . 29, 2024 05:25 Back to list

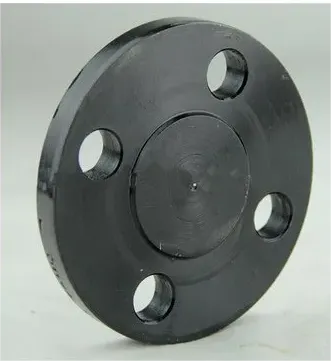

blind flange ansi 150

Understanding Blind Flanges ANSI 150 Specifications

In the realm of piping systems and industrial applications, flanges play an essential role in connecting different components. Among various types of flanges, blind flanges hold particular significance. They are used to seal the ends of pipes or vessels, effectively stopping the flow of fluids or gases. This article will delve into blind flanges, specifically focusing on ANSI 150 specifications, their applications, advantages, and considerations for selection.

What is a Blind Flange?

A blind flange is a solid piece of material with no opening in the center, designed to seal the end of piping systems. It serves as a closure for the piping, preventing leakage and the ingress of contaminants. Blind flanges are often used in high-pressure and high-temperature applications where secure sealing is critical.

ANSI 150 Specifications

The American National Standards Institute (ANSI) establishes guidelines for various industrial standards, including flange dimensions and ratings. The ANSI 150 designation refers to a specific pressure rating, which indicates the maximum pressure that a flange can withstand at a given temperature. ANSI 150 flanges are designed for moderate pressure applications, making them suitable for many industrial processes.

Material Considerations ANSI 150 blind flanges can be manufactured from a variety of materials, including carbon steel, stainless steel, and alloys. The choice of material is crucial as it influences the flange's resistance to corrosion, temperature fluctuations, and pressure levels.

Dimensions According to ANSI standards, blind flanges come in standardized sizes, accommodating different pipe dimensions. This standardization ensures compatibility with other piping components, facilitating ease of installation and maintenance.

Applications of ANSI 150 Blind Flanges

The versatility of ANSI 150 blind flanges allows them to be used in various industries, including

1. Oil and Gas Blind flanges are commonly employed in oil and gas pipelines, where the safe containment of fluids is paramount. They can be used to isolate sections of pipelines for maintenance or to seal unused connections.

2. Water Treatment In water treatment facilities, blind flanges are utilized to block off piping connections that are not currently in use, ensuring a safe and effective water flow system.

3. Chemical Processing The chemical industry often employs ANSI 150 blind flanges in reactors and storage vessels, where secure sealing is essential to prevent leaks that could result in hazardous situations.

blind flange ansi 150

Advantages of Using ANSI 150 Blind Flanges

1. Leak Prevention The primary advantage of blind flanges is their ability to create a tight seal, effectively preventing leaks in piping systems. This is crucial in industries dealing with hazardous materials.

2. Ease of Maintenance Blind flanges allow for easy isolation of pipe sections, facilitating maintenance and inspection without the need to dismantle the entire system.

3. Cost-Effective Using ANSI 150 blind flanges can be a cost-effective solution, as they eliminate the need for additional valves and fittings, simplifying the piping layout.

4. Durability When made from high-quality materials, ANSI 150 blind flanges can withstand adverse operating conditions, ensuring a long service life and reducing the frequency of replacements.

Considerations for Selection

When selecting ANSI 150 blind flanges, several factors should be considered

1. Pressure and Temperature Ratings Ensure the selected flange can handle the specific pressure and temperature conditions of the application.

2. Material Compatibility Choose a material that is compatible with the fluids or gases being carried in the piping system to minimize the risk of corrosion.

3. Size and Dimensions Verify that the flange dimensions align with existing piping components for a secure fit.

4. Standards Compliance Always ensure that the chosen blind flanges meet industry standards and specifications to maintain safety and regulatory compliance.

Conclusion

Blind flanges, particularly those adhering to ANSI 150 specifications, are indispensable components in various piping systems. Their ability to effectively seal pipe ends, coupled with their durability and ease of maintenance, makes them a preferred choice across different industries. By understanding the characteristics, applications, and considerations for ANSI 150 blind flanges, engineers and maintenance professionals can make informed decisions that enhance the safety and efficiency of their operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024

-

DIN2605-2617 Butt-Welding Fittings LR/SR 45°/90°/180° Seamless/Weld

NewsApr.23,2024