-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

Dec . 12, 2024 11:09 Back to list

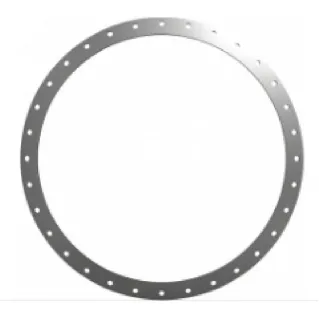

24 steel pipe cap

Understanding 24% Steel Pipe Caps A Comprehensive Overview

Steel pipe caps are crucial components in various industries, serving a vital purpose in sealing the ends of pipes to prevent contamination, loss of pressure, and provide protection from external elements. Among the various types of pipe caps, those made from 24% steel have gained significant attention for their durability and reliability.

What is 24% Steel?

Before delving into the specifics of steel pipe caps, it is essential to understand what 24% steel signifies. The term generally refers to a type of steel that contains 24% of alloying elements. This can include various metals such as chromium, nickel, and molybdenum, which enhance the properties of the steel, making it more robust, corrosion-resistant, and suitable for high-pressure applications.

The Significance of Steel Pipe Caps

Steel pipe caps are commonly used in several industries, including oil and gas, water supply, and construction. These caps serve multiple functions

1. Preventing Contamination When pipes are not in use, their open ends can attract dirt, debris, and even pests. Caps effectively block these unwanted elements, ensuring the integrity of the pipes when they are returned to service.

2. Pressure Maintenance In applications involving liquids or gases under pressure, steel caps help maintain the pressure within the pipe system. This is particularly crucial in industries like oil and gas, where even a minor leak can result in significant losses and safety hazards.

3. Corrosion Protection Steel pipe caps provide a barrier against corrosive elements in the environment, prolonging the lifespan of the pipes they cover. This is especially important in environments exposed to moisture, chemicals, or harsh weather conditions.

Advantages of 24% Steel Pipe Caps

The use of 24% steel for pipe caps comes with several advantages

24 steel pipe cap

- Enhanced Strength The alloying elements within 24% steel improve its tensile strength, making it suitable for high-stress environments. This strength ensures that the caps can withstand substantial pressure without deforming or breaking.

- Corrosion Resistance The alloying materials also provide superior resistance to rust and corrosion. This means that 24% steel pipe caps are ideal for outdoor applications or environments with high moisture content, reducing maintenance needs and extending the lifespan of the piping system.

- Versatility Steel pipe caps made from this alloy can be molded into various shapes and sizes, making them applicable for different pipe diameters and fitting requirements. This versatility is essential for custom projects where pipe specifications may vary.

Applications of 24% Steel Pipe Caps

The use of 24% steel pipe caps spans multiple sectors

- Oil and Gas Industry In high-pressure scenarios like pipelines that transport oil and natural gas, these caps are essential for pressure containment and preventing spills.

- Water Treatment Facilities Water systems require effective sealing to prevent contamination and maintain the quality of the treated water. 24% steel pipe caps are commonly used in these settings.

- Construction Often used to seal temporary construction pipelines, these caps ensure that construction sites remain safe and organized, while also protecting materials from the elements.

Conclusion

In conclusion, 24% steel pipe caps play an essential role in various industries by ensuring the safe sealing and protection of pipes. Their strength, corrosion resistance, and versatility make them an invaluable choice for applications across oil and gas, water supply, and construction. As industries continue to evolve and innovate, the importance of reliable components like 24% steel pipe caps will undoubtedly strengthen, highlighting the need for quality and resilience in piping solutions. Investing in high-quality steel pipe caps is not just a matter of compliance; it is a commitment to safety, efficiency, and longevity in any piping system.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024

-

DIN2605-2617 Butt-Welding Fittings LR/SR 45°/90°/180° Seamless/Weld

NewsApr.23,2024