-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

Aug . 23, 2025 00:40 Back to list

API X65 Pipe: Premium High-Strength Steel & PSL2 Grade

Navigating the Landscape of High-Strength Line Pipe: The Role of API 5L X65

In the critical infrastructure sectors of oil, gas, and petrochemicals, the demand for pipeline materials capable of withstanding extreme pressures, corrosive environments, and extensive operational lifespans is paramount. This necessitates the use of high-grade steel pipes engineered for superior performance and reliability. Among these, the api x65 grade, specifically conforming to API Specification 5L, stands out as a foundational element for robust and efficient pipeline systems. Its robust mechanical properties and adherence to stringent industry standards make it an indispensable choice for transporting hydrocarbons over long distances and under demanding conditions.

The global energy landscape is continuously evolving, driving significant trends in pipeline construction. There's an escalating emphasis on developing pipelines that offer enhanced safety, reduced environmental impact, and increased operational efficiency. This includes projects requiring higher operating pressures, larger diameters, and improved resistance to stress corrosion cracking (SCC). The adoption of advanced pipeline materials like API 5L X65 directly addresses these imperatives, allowing for thinner wall sections at equivalent pressure ratings, thereby reducing material costs and welding time. Furthermore, the push towards developing remote and challenging geographical energy reserves mandates materials that can be reliably deployed and maintained, highlighting the critical role of durable and high-performance steels such as the api x65 pipe in modern energy infrastructure development. Industry reports indicate a steady growth in the demand for high-strength low-alloy (HSLA) steels in pipeline applications, projected to reach significant market valuations by the end of the decade, underscoring the sustained importance of grades like API 5L X65.

Technical Specifications and Industry Standards of API 5L X65

The api x65 grade is specified under the American Petroleum Institute (API) Specification 5L, which defines standards for line pipe suitable for use in conveying gas, water, and oil in the natural gas and petroleum industries. The "X65" designation indicates a minimum yield strength of 65,000 psi (448 MPa). This high yield strength is a critical factor for pipeline design, enabling the construction of pipelines with greater internal pressure capacities or, alternatively, allowing for reduced wall thickness without compromising structural integrity.

API 5L X65 pipes are available in two product specification levels (PSL): PSL1 and PSL2. API 5L X65 PSL2 offers more stringent requirements compared to PSL1, including additional mandatory tests, specific chemical composition limits for carbon equivalent (CEQ), and superior toughness properties, often requiring Charpy V-notch impact tests. This enhanced specification ensures the pipe's suitability for more demanding applications, particularly those exposed to low temperatures or high-stress conditions. The chemical composition of steel API 5L X65 is carefully controlled to achieve its mechanical properties, typically featuring low carbon content for good weldability, along with micro-alloying elements like Manganese, Niobium, Vanadium, and Titanium to enhance strength and toughness through fine grain structure and precipitation hardening mechanisms. Understanding these precise metallurgical characteristics is crucial for engineers designing long-distance transmission lines and complex process piping systems.

Key Specifications for API 5L X65 Pipe

Note: Values presented are typical and may vary slightly between manufacturers or specific order requirements within API 5L X65 specification. For precise project requirements, always refer to the specific API 5L X65 PSL2 specification.

Manufacturing Process Flow for API 5L X65 Pipe

The production of api x65 pipe involves a meticulously controlled multi-stage manufacturing process designed to ensure adherence to the stringent API 5L X65 specification. The quality and performance of the final product are directly dependent on the precision and consistency maintained throughout each step.

- Raw Material Selection: The process begins with selecting high-quality steel slabs or billets, typically made from low-carbon, micro-alloyed steel. These materials are chosen for their specific chemical composition, which allows for the desired mechanical properties, including strength, toughness, and weldability, after subsequent processing.

-

Forming (Seamless or Welded):

- Seamless Pipe Production: For x65 seamless pipe, solid billets are heated in a rotary furnace and then pierced by a mandrel to form a hollow shell. This shell is then elongated and sized through multiple rolling stands to achieve the desired outer diameter and wall thickness. This method is preferred for high-pressure applications where integrity without welded seams is critical.

-

Welded Pipe Production: For welded pipes (e.g., ERW, LSAW, DSAW), steel plates or coils are first uncoiled and flattened. They are then formed into a cylindrical shape.

- ERW (Electric Resistance Welding): Edges are heated by electric current and pressed together to form a bond without filler metal. Suitable for smaller diameters.

- LSAW (Longitudinal Submerged Arc Welding): Large plates are cold-formed into a cylinder and then welded along the seam using submerged arc welding. Offers high strength and toughness for large-diameter pipes.

- DSAW (Double Submerged Arc Welding): Similar to LSAW, but with internal and external welds, providing superior weld integrity.

- Heat Treatment: Post-forming, pipes typically undergo specific heat treatment processes such as normalizing, quenching, and tempering. This refines the grain structure, enhances mechanical properties, particularly toughness and strength, and relieves internal stresses. This is crucial for achieving the specified API 5L X65 mechanical properties.

- Sizing and Straightening: After heat treatment, pipes are precisely sized to meet dimensional tolerances and straightened to ensure linearity, which is vital for efficient installation.

- End Preparation: Pipe ends are typically beveled to prepare for welding in the field, conforming to relevant industry standards like ASME B16.25.

- Non-Destructive Testing (NDT): Comprehensive NDT methods are employed to detect any internal or surface flaws. These include ultrasonic testing (UT), radiographic testing (RT), magnetic particle inspection (MPI), and eddy current testing. Adherence to international standards like ISO 9712 and ASTM E-series is strictly followed.

- Hydrostatic Testing: Each section of pipe undergoes hydrostatic testing, where it is filled with water and pressurized to a level significantly exceeding its maximum operating pressure. This test verifies the pipe's integrity and leak-tightness under pressure, a critical requirement for pipeline safety.

- Coating and Marking: Finally, pipes may receive external coatings for corrosion protection (e.g., 3LPE, FBE) and are marked with indelible information including the API monogram, size, grade (api5lx65), heat number, and manufacturer's identification, ensuring full traceability and compliance.

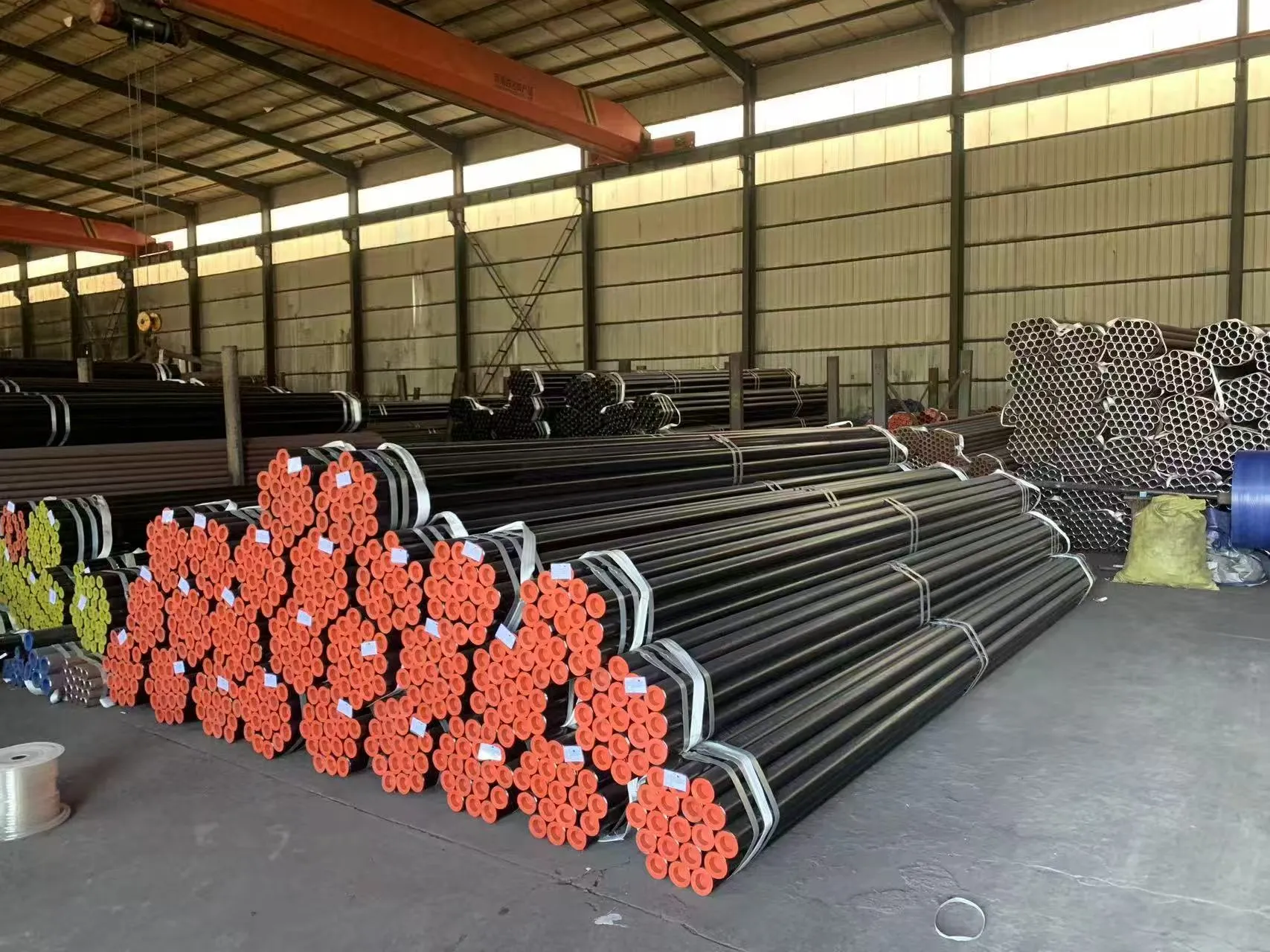

Figure 1: Illustration of a typical manufacturing stage for api 5l x65 pipe, showcasing quality control measures.

The rigorous nature of this manufacturing process, coupled with adherence to ISO 9001 quality management systems and ANSI standards for dimensions and testing, guarantees a product with exceptional service life, typically exceeding 50 years under normal operating conditions. This robust production methodology ensures that each steel api 5l x65 pipe meets the exact specifications required for the demanding petrochemical, metallurgy, and water supply & drainage industries, providing significant advantages in terms of corrosion resistance and operational safety.

Technical Advantages and Performance of API 5L X65

The inherent advantages of api x65 pipe make it a preferred material for critical applications where reliability and longevity are non-negotiable. Its superior mechanical properties directly translate into significant operational and economic benefits.

- High Strength-to-Weight Ratio: The high yield strength of API 5L X65 allows for the use of thinner wall pipes compared to lower-grade steels for the same pressure rating. This reduces material tonnage, fabrication costs, and logistical expenses, particularly in large-scale projects.

- Excellent Weldability: Despite its high strength, API 5L X65 is designed with a controlled chemical composition (low carbon equivalent) to ensure excellent weldability. This is crucial for field installation, where efficient and reliable welding procedures are essential for project timelines and overall pipeline integrity.

- Superior Toughness: Especially for API 5L X65 PSL2, enhanced toughness properties, including excellent Charpy V-notch impact values at low temperatures, provide resistance against brittle fracture, ensuring integrity in cold environments and under dynamic loading conditions. This contributes significantly to extending the service life of pipelines.

- Corrosion Resistance: While not inherently corrosion-proof, the dense and homogeneous microstructure of API 5L X65, when combined with appropriate internal and external coatings (e.g., FBE, 3LPE, internal epoxy), offers robust protection against various forms of corrosion, including external atmospheric corrosion and internal corrosive fluid transport. This directly translates to reduced maintenance costs and enhanced environmental safety by preventing leaks.

- Fatigue Resistance: The refined grain structure and controlled manufacturing process endow api 5l x65 gr x65 with superior fatigue resistance, crucial for pipelines subjected to cyclic loading, pressure fluctuations, or vibrational stresses over decades of operation.

Performance Comparison: API 5L X65 vs. Lower Grades

Table 2: Comparison of key mechanical properties and project implications for different API 5L grades.

The economic advantage of api 5l x65 psl2 is not just in its performance but also in its potential for cost-efficiency. By allowing for reduced wall thicknesses, projects can decrease overall steel tonnage, freight costs, and welding time, contributing to significant energy saving throughout the project lifecycle and operational phases.

Application Scenarios and Target Industries

The robust properties of x65 pipe make it an indispensable material across a spectrum of demanding industries. Its ability to handle high pressures and challenging environmental conditions positions it as a critical component in infrastructure where reliability cannot be compromised.

- Oil and Gas Transmission Lines: This is the primary application for API 5L X65. Long-distance pipelines transporting crude oil, natural gas, and refined petroleum products, both onshore and offshore, heavily rely on the high strength and toughness of api 5l x65. Its capacity to operate under high pressures facilitates efficient transport over vast distances, including transcontinental and subsea routes.

- Petrochemical Industry: Within refineries and chemical processing plants, API 5L X65 is used for process piping systems handling various hydrocarbons and chemical intermediates. Its resistance to specific corrosive agents, when coupled with appropriate coatings, ensures operational integrity in complex chemical environments.

- Power Generation: Although less common than for oil and gas, certain high-pressure steam lines or cooling water systems in thermal power plants may utilize API 5L X65 for its high-temperature strength and corrosion resistance, especially in sections requiring enhanced structural integrity.

- Water Supply and Drainage (Large Scale): For large-diameter municipal water transmission mains, especially those requiring high pressure due to terrain or long-distance pumping, the structural strength of api 5l x65 pipe can be advantageous. Its durability ensures a long service life and reduces the frequency of costly repairs.

- Mining and Slurry Pipelines: In the mining sector, pipes are often used to transport abrasive slurries over long distances. While specific wear-resistant linings are crucial, the underlying strength of API 5L X65 provides the structural integrity necessary to withstand the high pressures and external loads inherent in such demanding applications.

In a typical application scenario, consider an offshore gas pipeline project in a deep-water environment. Here, the pipeline must withstand immense external hydrostatic pressure, internal operational pressure, and dynamic loads from ocean currents. An api x65 seamless pipe, specified to API 5L X65 PSL2, would be chosen for its superior yield strength, ensuring pipe integrity and preventing buckling, and its high toughness to resist fracture during laying and operation in low-temperature seabed conditions. The ability to use a thinner wall due to the high strength also minimizes overall weight, reducing installation costs and the load on support structures, leading to significant energy saving and enhanced project economics over its projected decades-long service life.

Vendor Comparison and Customized Solutions for API 5L X65 Pipe

Selecting the right supplier for api 5l x65 pipe is as crucial as specifying the correct material. A reputable supplier offers not only compliant products but also comprehensive technical support, quality assurance, and flexible customization options. Key factors for B2B decision-makers and engineers to consider when evaluating api 5l x65 pipe suppliers include manufacturing capabilities, quality certifications, experience with complex projects, and the ability to provide tailored solutions.

Key Considerations for Supplier Selection:

- Certifications and Compliance: Verify that the supplier holds relevant industry certifications, such as API 5L monogram license, ISO 9001 for quality management, and adheres to specific regional standards. This guarantees that the api 5l x65 psl2 specification is consistently met.

- Manufacturing Expertise: Assess the supplier's experience in producing seamless vs. welded x65 seamless pipe, their quality control procedures, and their track record for delivering large-scale projects on time and within specification.

- Traceability and Documentation: Ensure complete material traceability from raw material to final product, alongside comprehensive mill test reports (MTRs) and documentation for all inspections and tests performed.

- Logistics and Delivery Capabilities: Evaluate their ability to handle complex logistics, especially for international projects, and their commitment to agreed-upon lead times.

Customized Solutions:

Many projects require more than standard pipe lengths and dimensions. Reputable suppliers offer a range of customized solutions to meet unique project demands:

- Custom Lengths: Providing pipes cut to specific lengths minimizes field welding and waste, optimizing construction efficiency.

- Special Coatings and Linings: Application of advanced internal linings (e.g., epoxy, cement mortar) for fluid compatibility and external coatings (e.g., 3LPE, FBE, coal tar enamel) for enhanced corrosion protection in specific environments.

- End Finishes: Beyond standard beveling, specialized end preparations for specific welding techniques or connections.

- Ancillary Services: Some suppliers offer bending, fabrication, and even project management support, streamlining the procurement process.

Figure 2: Custom pipe coating application on api 5l x65 pipe for enhanced corrosion resistance.

A supplier with decades of experience, such as YL Steel Fittings, which has been serving the industry for over 20 years, not only understands the intricacies of api 5l x65 specification but also offers the flexibility and technical acumen to deliver precise, project-specific solutions, ensuring optimal performance and cost-effectiveness for complex pipeline infrastructure.

Application Case Studies and Customer Experience

Real-world application demonstrates the tangible benefits and reliability of api x65 pipe in demanding environments. These case studies highlight how high-strength line pipe contributes to project success, operational efficiency, and long-term asset integrity.

Case Study 1: Transcontinental Gas Pipeline Expansion Project

A major energy consortium embarked on a multi-billion dollar expansion of a gas transmission network spanning over 1,500 km across varied terrain, including mountainous regions and wetlands. The project required pipes capable of handling pressures up to 10 MPa (1450 psi) and resisting localized ground movement. The decision was made to exclusively use 48-inch diameter api 5l x65 psl2 pipe with a specific wall thickness. The advanced mechanical properties of X65 allowed for a reduction in steel tonnage by approximately 15% compared to using X52 grade, leading to substantial savings in material costs and transportation. Furthermore, the excellent weldability of API 5L X65 facilitated faster field welding, reducing the overall construction timeline by several months. Post-installation, the pipeline successfully underwent rigorous hydrostatic testing and has operated reliably for over five years, exceeding performance expectations regarding flow rates and minimal pressure loss.

"The selection of API 5L X65 was pivotal for our transcontinental pipeline. It delivered the required strength and toughness, allowing for efficient construction and a high level of operational confidence. Our partnership with a trusted API 5L X65 pipe suppliers ensured timely delivery of customized lengths and rigorous quality control."

Case Study 2: Offshore Oil Field Development

An independent oil and gas company developed a new offshore field in the North Sea, requiring an export pipeline capable of withstanding harsh marine conditions and high internal pressures. The pipeline, comprising 30-inch diameter x65 seamless pipe, was laid at depths of over 500 meters. The high yield strength of X65 was critical for preventing buckling during the deep-water laying process and ensuring structural integrity against external hydrostatic pressure. The specified API 5L X65 PSL2 material, with its guaranteed impact toughness at low temperatures, offered superior resistance to brittle fracture, a significant concern in cold-water environments. The meticulous manufacturing process, including stringent NDT and hydrostatic testing, provided the necessary assurance for this challenging project. The pipeline has been fully operational for three years, demonstrating exceptional performance in a highly corrosive and high-stress environment, affirming the long-term reliability of API 5L X65.

These case studies illustrate that the choice of API 5L X65 pipe is an investment in long-term operational excellence, safety, and economic efficiency. The positive customer feedback and sustained performance in diverse and challenging applications underscore the material's authoritative standing in the pipeline industry.

Ensuring Trustworthiness: FAQ, Lead Time, Warranty, and Support

Transparency and comprehensive support are cornerstones of trustworthy B2B partnerships. For critical components like api x65 pipe, understanding lead times, warranty terms, and available customer support is vital for project planning and risk mitigation.

Frequently Asked Questions (FAQ)

- Q: What is the primary difference between API 5L X65 PSL1 and PSL2?

- A: API 5L X65 PSL2 has more rigorous requirements, including mandatory Charpy impact testing, stricter chemical composition limits (especially for carbon equivalent), and higher manufacturing quality controls, making it suitable for more critical and demanding applications than PSL1.

- Q: Can x65 pipe specification be customized for specific pressure ratings?

- A: While the X65 grade defines minimum yield strength, pipe dimensions (outer diameter and wall thickness) are specified to meet required pressure ratings according to design codes like ASME B31.3 or B31.4. Suppliers can manufacture pipes to specific OD and WT combinations within the API 5L X65 specification.

- Q: What welding procedures are recommended for api 5l x65 pipe?

- A: Due to its low carbon equivalent, API 5L X65 generally exhibits good weldability. Common procedures include Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Submerged Arc Welding (SAW). Specific preheating and post-weld heat treatment may be required depending on wall thickness and service conditions to ensure optimal weld integrity and mechanical properties, as per project-specific WPS (Welding Procedure Specification).

- Q: What is the typical service life of API 5L X65 pipe?

- A: With proper design, installation, coating, cathodic protection, and maintenance, API 5L X65 pipelines are engineered for a service life of 50 years or more, demonstrating exceptional durability and reliability in diverse operating environments.

Lead Time and Fulfillment

Lead times for api 5l gr x65 pipe vary based on quantity, dimensions, specific customization requirements (e.g., coatings), and current mill schedules. Reputable suppliers typically provide estimated lead times upon inquiry and maintain transparent communication throughout the order fulfillment process. For standard sizes and quantities, lead times can range from 4-8 weeks, while highly customized or large-volume orders may require longer. Efficient logistics and global shipping capabilities ensure timely delivery to project sites worldwide.

Warranty Commitments

Products supplied, including steel api 5l x65, typically come with a standard manufacturer's warranty against defects in material and workmanship, adhering strictly to API 5L and other applicable industry standards. This warranty generally covers a period of 12 to 24 months from the date of shipment or commissioning, whichever comes first. Specific warranty details are outlined in the sales agreement and aim to provide peace of mind regarding product quality and compliance.

Customer Support and After-Sales Service

Dedicated customer support is available to assist clients with technical queries, order tracking, and any post-delivery concerns. This includes access to experienced engineers and technical specialists who can provide guidance on material selection, welding procedures, and installation best practices for api 5l x65 pipe specification. Comprehensive after-sales service reinforces our commitment to client success and long-term partnership.

Conclusion

The api 5l x65 pipe stands as a testament to advanced metallurgical engineering, providing the backbone for critical energy and infrastructure projects worldwide. Its high strength, superior toughness, and excellent weldability, backed by rigorous API 5L X65 PSL2 specification, make it an optimal choice for high-pressure, long-distance transmission lines in the oil, gas, and petrochemical industries. As global energy demands continue to rise and infrastructure projects become increasingly complex and environmentally sensitive, the inherent advantages of this grade, including reduced material consumption, enhanced safety, and extended service life, will only grow in significance. Investing in high-quality API 5L X65 pipe from certified and experienced suppliers ensures not only project compliance but also contributes significantly to the long-term operational efficiency and sustainability of critical assets. For B2B decision-makers and engineers, choosing API 5L X65 is a strategic decision for performance, reliability, and cost-effectiveness in the face of evolving industry challenges.

References

- American Petroleum Institute. API Specification 5L: Specification for Line Pipe. 46th Edition, 2018.

- International Organization for Standardization. ISO 3183: Petroleum and natural gas industries -- Steel pipe for pipeline transportation systems. 3rd Edition, 2012.

- ASM International. "ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys." 10th Edition, 1990.

- Wang, Y., & Liu, X. (2019). "Development and Application of High-Strength Pipeline Steels." Journal of Materials Science & Technology, Vol. 35, Issue 5, pp. 881-890.

- European Committee for Standardization. EN 10204: Metallic products - Types of inspection documents. 2004.

This is the last article

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024

-

DIN2605-2617 Butt-Welding Fittings LR/SR 45°/90°/180° Seamless/Weld

NewsApr.23,2024