Key Features:

- Secure threaded connection for reliable sealing

- Versatile application across industries

- Ease of installation with simple threading process

- Durable construction for long-term performance

- Precision engineering for tight tolerances

- Compliance with ANSI B16.5 standards

-

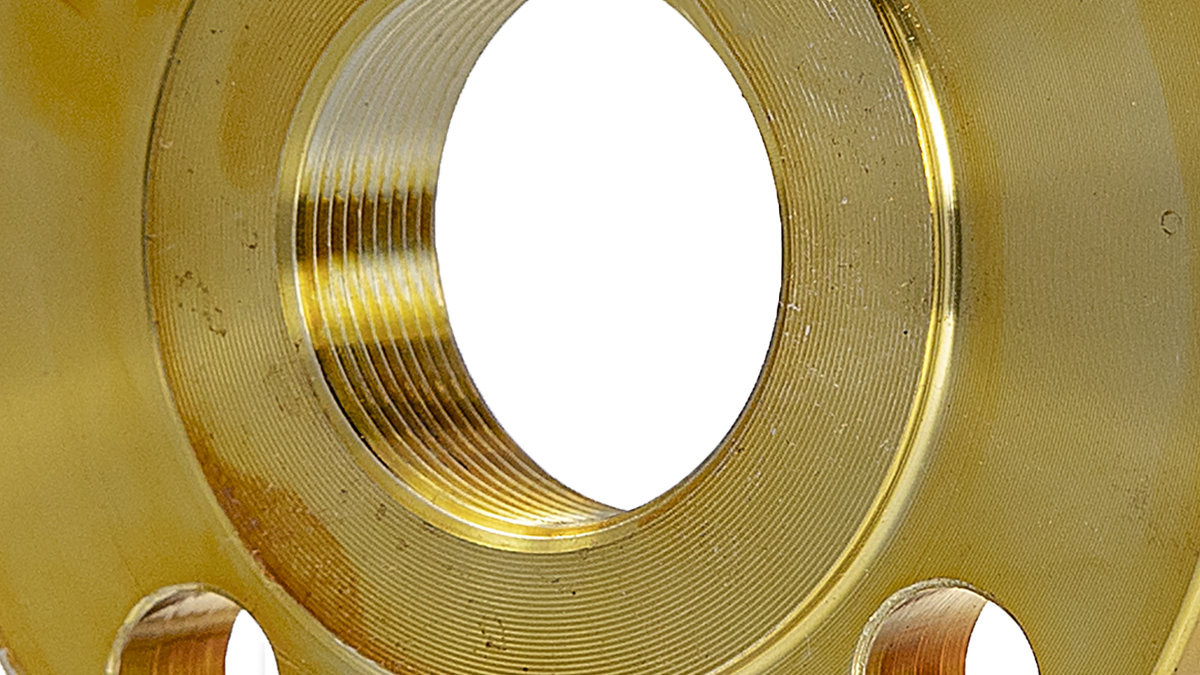

Secure Threaded Connection: The ANSI B16.5 Threaded Flange features internal threads that allow for a tight and secure connection with externally threaded pipes or fittings. This threaded connection ensures a reliable seal, preventing leakage and maintaining the integrity of the piping system, even under high-pressure conditions.

-

Versatile Application: From chemical processing plants and refineries to water distribution networks and HVAC systems, ANSI B16.5 Threaded Flanges find versatile application across various industries. Whether used for connecting pipes, valves, or equipment components, these flanges offer flexibility and reliability in critical piping systems.

-

Ease of Installation: Installing ANSI B16.5 Threaded Flanges is straightforward and efficient, requiring only the matching of internal and external threads and tightening with a wrench. This ease of installation simplifies the assembly process, reduces downtime, and enhances overall project efficiency.

-

Durable Construction: Constructed from robust materials such as carbon steel, stainless steel, or alloy steel, ANSI B16.5 Threaded Flanges exhibit exceptional strength and durability. They are engineered to withstand harsh operating conditions, including high temperatures, corrosive environments, and intense pressure, ensuring long-term performance and reliability.

-

Precision Engineering: ANSI B16.5 Threaded Flanges undergo precision machining and engineering processes to meet strict dimensional tolerances and surface finish requirements. This precision ensures compatibility and interchangeability with other ANSI B16.5 standard flanges, facilitating seamless integration into piping systems and minimizing the risk of leaks or failures.

-

Compliance with Standards: ANSI B16.5 Threaded Flanges conform to the specifications outlined in the ANSI B16.5 standard, as well as other relevant industry standards and regulations. This compliance ensures consistency in design, manufacturing, and performance, providing assurance of quality and reliability to customers.