ASTM A53 PIPE Material composition

Carbon (C) : Usually the content is about 0.25%-0.30%, carbon is an important element affecting the strength and toughness of steel, in this range to ensure that the steel pipe has a certain strength and processing properties.

Manganese (Mn) : The content is generally 0.60%-1.05%, manganese can improve the strength and toughness of steel, but also improve the thermal processing performance of steel.

Silicon (Si) : the general content is 0.15%-0.30%, silicon mainly plays a deoxidation role in steel, which can increase the strength and hardness of steel.

Sulfur (S), phosphorus (P) : sulfur content is usually ≤0.05%, phosphorus content ≤0.045%, they are harmful elements, the content is too high will lead to the toughness of steel decline, increase cold brittleness and hot brittleness, need to be strictly controlled.

ASTM A53 PIPE Manufacturing process

Seamless steel pipe: The use of perforation, rolling and other processes, the entire pipe wall without weld, with high strength and sealing, suitable for high pressure, high temperature and other pipe requirements of the occasion.

Welded steel pipe: by rolling steel plate or steel strip into a tube and welding, according to different welding methods can be divided into resistance welding (ERW), submerged arc welding (SAW) and so on. Welded steel pipe has high production efficiency and low cost, and is widely used in the field of general fluid transportation and structural support.

ASTM A53 PIPE Mechanical property

Tensile strength: The tensile strength of grade A steel pipe is not less than 330MPa, and the tensile strength of grade B steel pipe is not less than 415MPa. The high tensile strength enables the steel pipe to withstand greater tension, ensuring that it will not break easily when transporting fluid or as a structural part.

Yield strength: The yield strength of grade A steel pipe is not less than 205MPa, and the yield strength of grade B steel pipe is not less than 240MPa. The yield strength is a measure of the steel pipe resistance to plastic deformation, reaching the corresponding standard can ensure that the steel pipe in the normal use of the process will not occur excessive deformation.

Elongation: According to the specifications and types of steel pipes, the elongation is generally about 20%-30%. The elongation rate reflects the plasticity and toughness of the steel pipe, and the high elongation rate means that the steel pipe can have a certain deformation ability when it is subjected to external force, and it is not easy to be brittle.

ASTM A53 PIPE Surface treatment

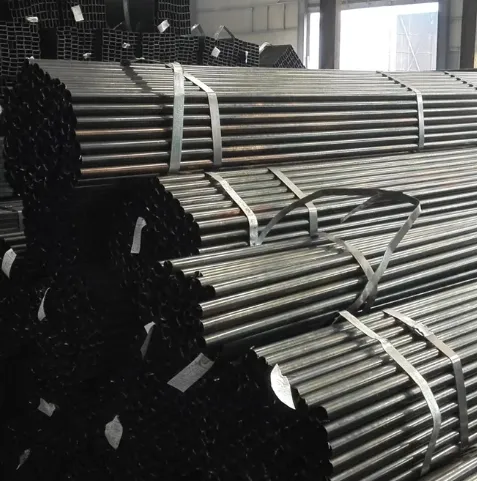

Black tube: that is, the original steel pipe without surface treatment, the surface retains the natural state after rolling or welding, there may be oxide skin, etc., generally used for occasions where the corrosion resistance is not high or further processing is required.

Galvanized pipe: through hot dip galvanizing or electric galvanizing process on the surface of the steel pipe plated with a layer of zinc, zinc layer can effectively prevent rust corrosion of the steel pipe, extend the service life, often used in building water supply, gas transmission and other areas requiring corrosion resistance.

-

Cangzhou Yulong Steel Co., Ltd.

-

телефон:

+86 13303177267 -

Електронна поща:

admin@ylsteelfittings.com

- Английски

- арабски

- Италиански

- испански

- португалски

- Немски

- казахски

- персийски

- Гръцки

- Френски

- Руски

- полски

- тайландски

- индонезийски

- виетнамски

- зулу

- корейски

- узбекски

- не

- сръбски

- малайски

- украински

- гуджарати

- хаитянски креолски

- хауса

- хавайски

- иврит

- Мяо

- унгарски

- исландски

- игбо

- ирландски

- японски

- явански

- каннада

- кхмерски

- Руанда

- африкански

- албанец

- амхарски

- арменски

- азербайджански

- баски

- белоруски

- бенгалски

- босненски

- български

- каталонски

- себуано

- Китай

- Китай (Тайван)

- корсиканец

- хърватски

- чешки

- датски

- Есперанто

- естонски

- финландски

- фризийски

- галисийски

- грузински

- кюрдски

- киргизки

- туберкулоза

- латински

- латвийски

- литовски

- люксембургски

- македонски

- Малгаши

- малаялам

- малтийски

- маори

- маратхи

- монголски

- Мианмар

- непалски

- норвежки

- норвежки

- окситански

- Pashto

- холандски

- пенджабски

- румънски

- самоански

- шотландски келтски

- Английски

- Шона

- Синдхи

- сингалски

- словашки

- словенски

- сомалийски

- сундански

- суахили

- шведски

- тагалог

- таджикски

- тамилски

- татарски

- телугу

- Турски

- туркменски

- урду

- уйгурски

- уелски

- Помогне

- идиш

- йоруба

Напишете вашето съобщение тук и ни го изпратете

Related News

-

Jun . 18, 2025The 'Ultimate Shield' of Pipeline Systems: How Carbon Steel Pipe Caps Withstand the Dual Onslaught of High Pressure and Chemical CorrosionIn the high-stakes world of industrial piping, where failure can lead to catastrophic consequences, carbon steel pipe caps emerge as indispensable guardians, fending off both hydraulic pressure surges and corrosive media.

-

Jun . 18, 2025The Cost Revolution in Agricultural Irrigation: How Galvanized Steel Pipes Prolong Water Transmission System LifespanIn the realm of modern agriculture, where water efficiency and infrastructure durability are paramount, galvanized steel pipes have emerged as a game-changer for irrigation systems.