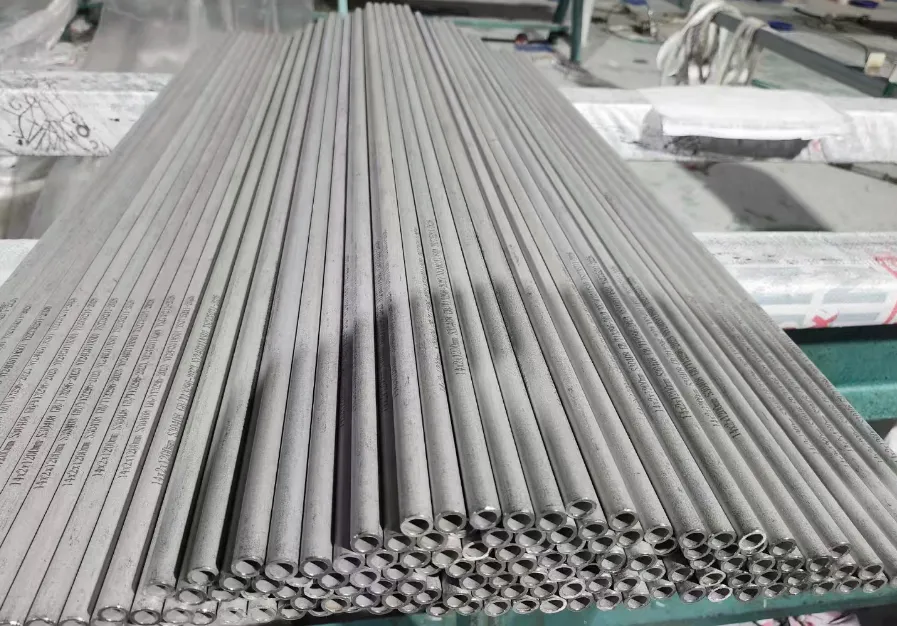

Steel Pipes - ASTM A358

| Specifications | Range |

| Out Diameter | 6NB to 1200NB |

| Wall Thickness | SCH.5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS |

ASTM A358 Standard for Electric-Fusion-Welded Austenitic Chromium-Nickel Stainless Steel Pipe for High-Temperature Service and General Applications. Covers electric-fusion-welded austenitic chromium-nickel stainless steel pipe suitable for corrosive or high temperature service, or both, or for general applications.

The pipes shall be sorted into five different classes. Class 1 pipes shall be double welded by processes employing filler metal in all passes and shall be completely radiographed. Pipes of Class 2 shall be double welded by processes employing filler metal in all passes with no radiography. Both Class 3 and Class 4 pipes shall be single welded except that the weld pass of the latter exposed to the inside pipe surface may be without the addition of filler metal.

Pipes of Class 5 shall be double welded by processes employing filler metal and shall be spot radiographed. Weld defects shall be repaired by removal to sound metal and rewelding. Subsequent heat treatment shall be as required on the original welds. The finished pipes shall be subjected to transverse tension test, transverse guided-bend weld test, and hydrostatic test.

This specification covers electric-fusion-welded austenitic chromium-nickel stainless steel pipe suitable for corrosive or high-temperature service, or both, or for general applications. The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter,”“size,” and “nominal size.”

This specification covers the grades of alloy and stainless steel listed in Table 1. The selection of the proper grade and requirements for heat treatment shall be at the discretion of the purchaser, dependent on the service conditions to be encountered.

Five classes of pipe are covered as follows:

Class 1—Pipe shall be double welded by processes employing filler metal in all passes and shall be completely radiographed.

Class 2—Pipe shall be double welded by processes employing filler metal in all passes. No radiography is required.

Class 3—Pipe shall be single welded by processes employing filler metal in all passes and shall be completely radiographed.

Class 4—Same as Class 3 except that the weld pass exposed to the inside pipe surface may be made without the addition of filler metal.

Class 5—Pipe shall be double welded by processes employing filler metal in all passes and shall be spot radiographed.

Supplementary requirements covering provisions ranging from additional testing to formalized procedures for manufacturing practice are provided. Supplementary Requirements S1 through S6 are included as options to be specified when desired. The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

Напишете вашето съобщение тук и ни го изпратете