DIN 2605-2617 standards encompass a range of industrial fittings, including butt-welding caps, that are widely used in piping systems. Caps serve the purpose of closing the end of a pipe, either temporarily or permanently, providing a seal to prevent leakage. Here is an introduction to DIN 2605-2617 butt-welding caps:

- 1.DIN 2605-2617 Standards:

- - DIN 2605-2617 standards define the requirements for the design, dimensions, material specifications, manufacturing, and testing of butt-welding fittings, including caps, used in piping systems.

- - These standards ensure that caps produced under DIN guidelines meet quality standards and are compatible with other components within the piping system.

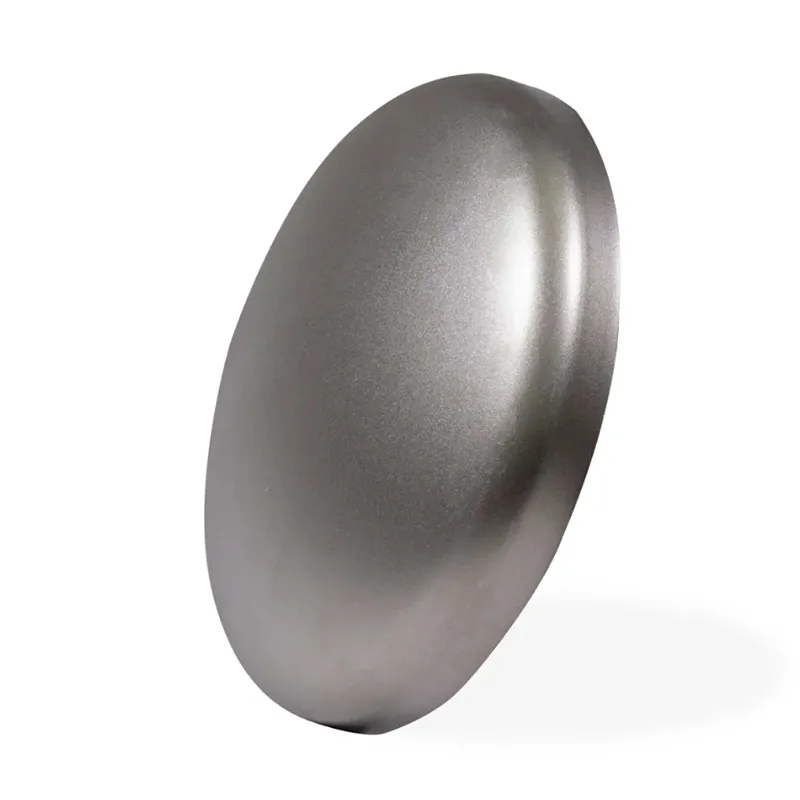

- 2. Butt-Welding Cap:

- - A butt-welding cap, as per DIN standards, is a fitting designed to cover the end of a pipe, closing it securely to prevent leakage or contamination.

- - Caps are often used for pipe ends that do not require future connections or where the end needs to be sealed permanently. They provide protection and maintain pipeline integrity.

- 3. Material and Construction:

- - Butt-welding caps conforming to DIN 2605-2617 standards are available in various materials, including carbon steel, stainless steel, and alloy steel, to cater to different application requirements.

- - These caps are manufactured using standardized construction methods to ensure a strong and leak-free connection when welded to the end of a pipe.

- 4. Application and Benefits:

- - Butt-welding caps find applications across industries like oil and gas, chemical processes, water treatment, and more where the end of pipes needs to be sealed securely.

- - Caps are used to protect pipe ends from environmental elements, contaminants, and corrosion, providing a barrier that helps maintain the integrity of the piping system.

- 5. Installation and Welding:

- - Proper installation practices, such as correct alignment, preparation of the pipe end, and welding techniques, are crucial when installing butt-welding caps to ensure a tight and leak-proof seal.

- - Welding is a common method for attaching caps to pipes, providing a permanent and reliable closure that can withstand pressure, temperature variations, and fluid flow within the system.

- In summary, DIN 2605-2617 butt-welding caps are essential components used in piping systems to seal the end of pipes securely and prevent leakage or contamination. These caps adhere to standardized specifications to ensure quality, reliability, and compatibility within industrial applications where pipe closure and protection are required.

Write your message here and send it to us