EN 10216 is a standard which covers steel grade P235TR2, which are well suited for pressure applications. Furthermore, European Standard EN 10216-1 specifies the technical delivery conditions for two qualities steels i.e. en 10216-1 p235tr1 and TR2. Both these steel qualities are seamless tubes produced with a circular cross-section. This standard also mentions specific properties at room temperature from products, for instance, EN 10216-1 Grade P235TR2 Alloy Steel Seamless Tubes manufactured from a quality of non-alloy steel.

While steels belonging to quality TR1 are used for applications involving the conveyance of different media, whereas steels under quality en 10216-1 p265tr2 are intended for use in systems for both pressure equipment and pipelines. Similar to most English standards, there are different designations that describe the use of the said steel grade. While the letter P suggests that the EN 10216 Seamless Steel Tubes is to be used for pressure purposes, the number 235 or 265 makes a mention of its minimum yield strength in N/mm2. The letters T designates a tube, whereas R is the designation for non alloy steels meant for ambient or room temperature use, with either number 1 or 2 indicating the quality of the en 10216-1 material.

Chemical Element of EN 10216-1 Seamless non-alloy steel tubes

| Steel grades | CHEMICAL COMPOSITION (LADLE ANALYSIS) | |||||||||||||

| C% max | Si% max | Mn% max | P% max | S% max | Cr% max | Mo% max | Ni% max | Al. cał% min | Cu% max | Nb% max | Ti% max | V% max | Cr + Cu+ Mo +Ni % MAX | |

| P195TR1 | 0,13 | 0,35 | 0,70 | 0,025 | 0,020 | 0,030 | 0,08 | 0,030 | - | 0,030 | 0,010 | 0,04 | 0,02 | 0,70 |

| P195TR2 | 0,13 | 0,35 | 0,70 | 0,025 | 0,020 | 0,030 | 0,08 | 0,030 | 0,02 | 0,030 | 0,010 | 0,04 | 0,02 | 0,70 |

| P235TR1 | 0,16 | 0,35 | 1,20 | 0,025 | 0,020 | 0,030 | 0,08 | 0,030 | - | 0,030 | 0,010 | 0,04 | 0,02 | 0,70 |

| P235TR2 | 0,16 | 0,35 | 1,20 | 0,025 | 0,020 | 0,030 | 0,08 | 0,030 | 0,02 | 0,030 | 0,010 | 0,04 | 0,02 | 0,70 |

| P265TR1 | 0,20 | 0,40 | 1,40 | 0,025 | 0,020 | 0,030 | 0,08 | 0,030 | - | 0,030 | 0,010 | 0,04 | 0,02 | 0,70 |

| P265TR2 | 0,20 | 0,40 | 1,40 | 0,025 | 0,020 | 0,030 | 0,08 | 0,030 | 0,02 | 0,030 | 0,010 | 0,04 | 0,02 | 0,7 |

| Grade | C | Si | Mn | P | S | Cr | Mo | Cu | Ni |

| P195 | ≤0.13 | ≤0.35 | ≤0.70 | ≤0.025 | ≤0.020 | ≤0.030 | ≤0.08 | ≤0.30 | ≤0.30 |

| P235 | ≤0.16 | ≤0.35 | ≤1.20 | ≤0.025 | ≤0.020 | ≤0.030 | ≤0.08 | ≤0.30 | ≤0.30 |

| P265 | ≤0.20 | ≤0.40 | ≤1.40 | ≤0.025 | ≤0.020 | ≤0.030 | ≤0.08 | ≤0.30 | ≤0.30 |

EN 10216 Seamless Steel Tubes Mechanical Properties

| Pipe types | Steel grades | Mechanical properties | Resilience | |||||||||

| Upper yield limit Re min for wall thickness T mm | Tensile strength Rm | Elongation A min |

Minimum energy average absorbed KV J at the temperature of 0°C | |||||||||

| T<\=16 | 16<T<\=40 | 40<T<\=60 | 1 | t | ||||||||

| MPa | MPa | MPa | MPa | 1 | t | 0 | -10 | 0 | ||||

| Line pipes P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

P195TR1 | 195 | 185 | 175 | 320-440 | 27 | 25 | - | - | - | ||

| P195TR2 | 195 | 185 | 175 | 320-440 | 27 | 25 | 40 | 28 | 27 | |||

| P235TR1 | 235 | 225 | 215 | 360-500 | 25 | 23 | - | - | - | |||

| P235TR2 | 235 | 225 | 215 | 360-500 | 25 | 23 | 40 | 28 | 27 | |||

| P265TR1 | 265 | 255 | 245 | 410-570 | 21 | 19 | - | - | - | |||

| P265TR2 | 265 | 255 | 245 | 410-570 | 21 | 19 | 40 | 28 | 27 | |||

| Grade | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation(%)L | Elongation (%)T |

| P195 | ≥195 | 320-440 | 27 | 25 |

| P235 | ≥235 | 360-500 | 25 | 23 |

| P265 | ≥265 | 410-570 | 21 | 19 |

EN 10216-1 Carbon Seamless Steel Tubes Wall Thickness Tolerances

| Outside | Tolerance on D |

Tolerances on T for a T/D ratio

|

|||

| diameter D | | <= 0.025 | > 0.025 | > 0.050 | > 0.10 |

| <= 0.050 | <= 0.10 | ||||

| D <= 219.1 mm | ± 1 % or ± 0.5 mm | ± 12.5 % or ± 0.4 mm whichever is greater | |||

| D > 219.1 mm | whichever is the greater | ± 20 % | ± 15 % | ± 12.5 % | ± 10 %* |

EN 10216-1 Tubes Inspection and test type

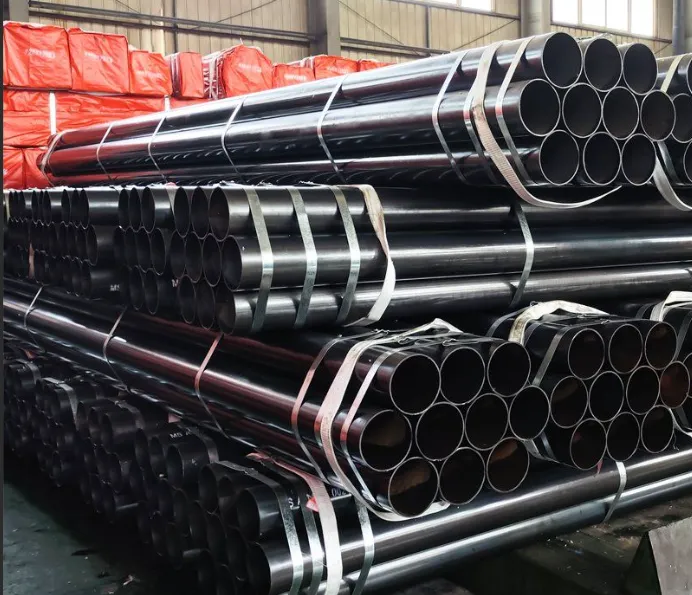

EN 10216-1 Grade P235TR2 Alloy Steel Seamless Tubes & heat exchanger tube in many sizes & surface finish

| Inspection and test type | Test frequency | |

| Mandatory tests | Ladle analysis | One ladle |

| Tensile testing | One per every tested batch | |

| Resilience testing at the temperature of 0ºC | ||

| Tightness testing | Every pipe | |

| Dimensional testing | - | |

| Visual inspection | - | |

| Optional tests | Ladle analysis | One ladle |

| Resilience testing on longitudinal samples at the temperature of -10ºC | One per every tested batch | |

| Wall thickness measurements at a distance from pipe ends | - | |

| Non-destructive testing in order to identify any longitudinal discontinuity | Every pipe | |