-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Mar . 03, 2025 12:48 Back to list

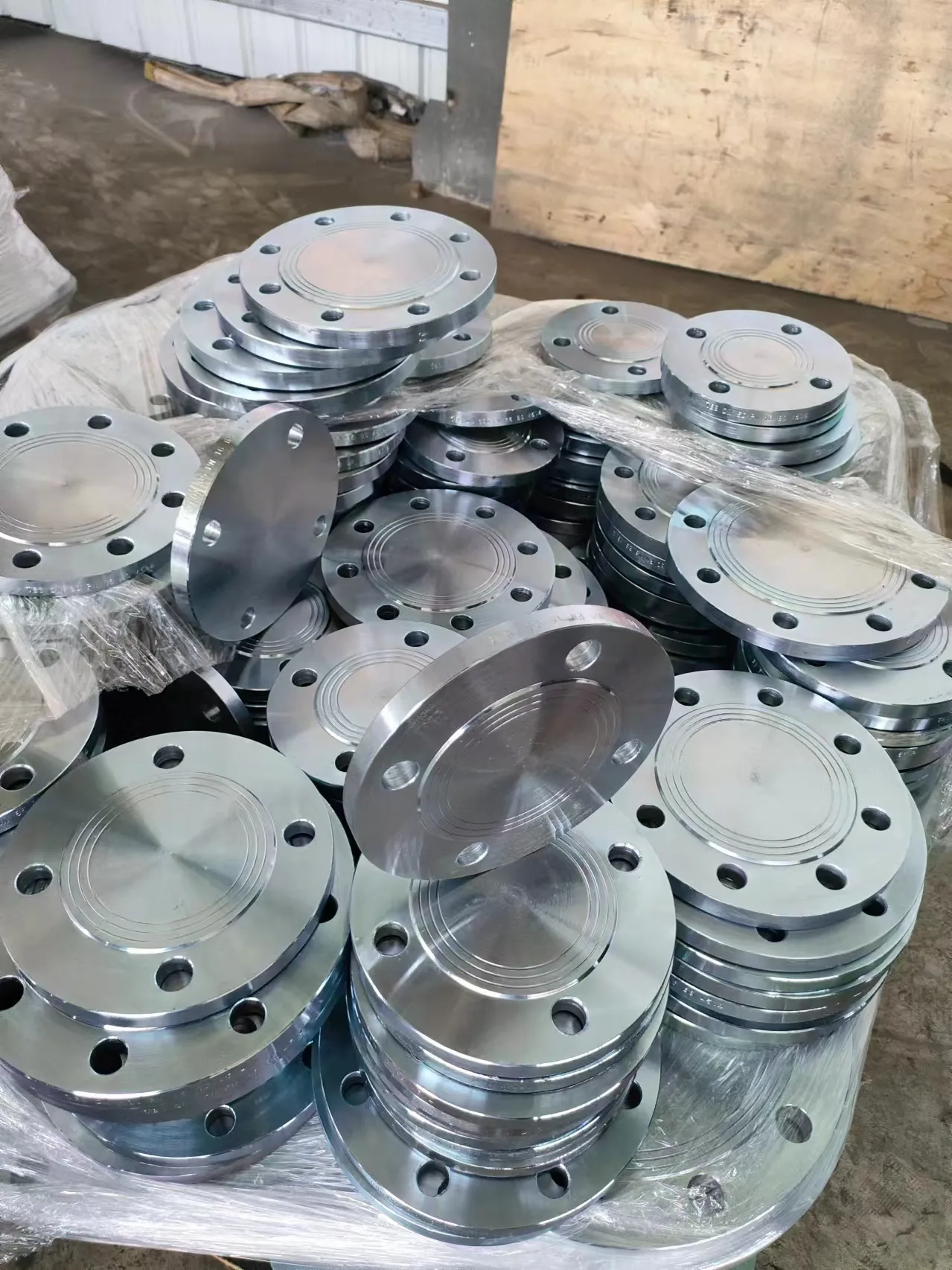

en1092 1 type 11

EN1092-1 Type 11 flange, a key component in the world of industrial piping, is essential for specialists seeking reliable solutions for connecting pipes, valves, pumps, and other equipment to form a comprehensive piping system. Professionals familiar with the intricacies of industrial installations recognize the paramount importance of choosing the right flange type, as it embodies the expertise, precision, and dependability required in high-pressure environments.

Trustworthiness of these flanges is paramount for industrial projects where any failure could result in catastrophic consequences. The meticulous production processes, thorough inspections, and adherence to international manufacturing standards bolster the confidence of stakeholders who rely on these components to uphold structural integrity. Many suppliers and manufacturers provide certification of compliance to these standards, which further reinforces their reliability and trustworthiness. Product experts and seasoned professionals in charge of installation or maintenance find that EN1092-1 Type 11 flanges offer significant advantages not just in installation, but also in the long-term durability of the system. These flanges enable facile welding to the pipeline, a critical factor for minimizing leakages and ensuring a robust fit. Weld neck flanges are particularly valuable in expansions and modifications, providing flexibility and adaptability without compromising the integrity of the connection. In the rapidly evolving landscape of industrial applications, selecting the appropriate flange type is essential. EN1092-1 Type 11 flanges represent a blend of technical proficiency, operational integrity, and institutional trust. Their authoritative backing, grounded in internationally recognized engineering principles, ensures they remain a staple in high-stakes industrial environments. For specialists endeavoring to optimize piping systems, these flanges offer a remarkable combination of experience-driven design, expert manufacturing, authoritative validation, and unyielding trustworthiness, fortifying their role as an indispensable component in global industrial frameworks.

Trustworthiness of these flanges is paramount for industrial projects where any failure could result in catastrophic consequences. The meticulous production processes, thorough inspections, and adherence to international manufacturing standards bolster the confidence of stakeholders who rely on these components to uphold structural integrity. Many suppliers and manufacturers provide certification of compliance to these standards, which further reinforces their reliability and trustworthiness. Product experts and seasoned professionals in charge of installation or maintenance find that EN1092-1 Type 11 flanges offer significant advantages not just in installation, but also in the long-term durability of the system. These flanges enable facile welding to the pipeline, a critical factor for minimizing leakages and ensuring a robust fit. Weld neck flanges are particularly valuable in expansions and modifications, providing flexibility and adaptability without compromising the integrity of the connection. In the rapidly evolving landscape of industrial applications, selecting the appropriate flange type is essential. EN1092-1 Type 11 flanges represent a blend of technical proficiency, operational integrity, and institutional trust. Their authoritative backing, grounded in internationally recognized engineering principles, ensures they remain a staple in high-stakes industrial environments. For specialists endeavoring to optimize piping systems, these flanges offer a remarkable combination of experience-driven design, expert manufacturing, authoritative validation, and unyielding trustworthiness, fortifying their role as an indispensable component in global industrial frameworks.

Next:

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024