-

Cangzhou Yulong Steel Co., Ltd.

-

Tillefoan:

+86 13303177267 -

E-post:

admin@ylsteelfittings.com

- Ingelsk

- Arabysk

- Italiaansk

- Spaansk

- Portegeesk

- Dútsk

- Kazachsk

- Perzysk

- Gryksk

- Frânsk

- Russysk

- Poalsk

- Taisk

- Yndonesysk

- Fietnameesk

- Zulu

- Koreaansk

- Uzbek

- Nee

- Servysk

- Maleisk

- Oekraynsk

- Gujaratysk

- Haïtiaansk Kreaolsk

- Hausa

- Hawaïaansk

- Hebrieuwsk

- Miao

- Hongaarsk

- Yslânsk

- igbo

- Iersk

- Japansk

- Javaansk

- Kannada

- Khmer

- Rwandan

- Afrikaanske

- Albaneesk

- Amhaarsk

- Armeensk

- Azerbeidzjaansk

- Baskysk

- Wytrussysk

- Bengaalsk

- Bosnysk

- Bulgaarsk

- Katalaansk

- Cebuano

- Sina

- Sina (Taiwan)

- Korsikaansk

- Kroatysk

- Tsjechysk

- Deensk

- Esperanto

- Estysk

- Finsk

- Frysk

- Galyskysk

- Georgysk

- Koerdysk

- Kirgizysk

- TB

- Latyn

- Letsk

- Litousk

- Lúksemboarchsk

- Masedoanysk

- Malgashi

- Malayalam

- Malteesk

- Maori

- Maratysk

- Mongoalsk

- Birma

- Nepaleesk

- Noarsk

- Noarsk

- Oksitaansk

- Pashtu

- Nederlânsk

- Pûndjaabsk

- Roemeensk

- Samoan

- Skotsk Gaelic

- Ingelsk

- Shona

- Sindysk

- Sinhala

- Slowaaksk

- Sloveensk

- Somalysk

- Sundanese

- Swahily

- Sweedsk

- Tagaloch

- Tajik

- Tamyl

- Tatar

- Telugu

- Turksk

- Turkmeensk

- Urdu

- Uighur

- Welsh

- Help

- Jiddysk

- Yoruba

Jun . 12, 2025 09:15 Werom nei list

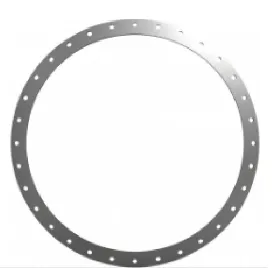

How To Measure DIN86044 Flange Dimensions Correctly

In the realm of industrial piping systems, DIN86044 flanges play a crucial role in ensuring secure and leak - free connections. These flanges are renowned for their specific design and dimensional standards, which are defined by the DIN 86044 flange standard. As a wholesaler, providing accurate guidance on measuring din 86044 flange dimensions is essential for helping customers select the right products and ensuring seamless installations. Cangzhou Yulong Steel Co., Ltd. manufactures high - quality DIN86044 flanges that adhere to strict standards, and understanding the correct measurement methods is key to leveraging the full potential of these products.

|

Key Features |

Description |

|

Robust ûntwerp foar marine tapassingen |

DIN86044 flanges are engineered with a sturdy construction, making them ideal for marine environments. Their robust build can withstand the harsh conditions of the sea, including strong waves, high pressures, and constant movement, ensuring reliable performance in shipbuilding, offshore platforms, and other marine - related projects. |

|

Korrosjebestriding foar duorsumens yn seewetteromjouwings |

These flanges are designed to resist corrosion caused by seawater. The materials used and manufacturing processes employed by Cangzhou Yulong Steel Co., Ltd. provide excellent protection against the corrosive effects of saltwater, extending the lifespan of the flanges and reducing maintenance costs in seawater - exposed installations. |

|

Seewetterkompatibiliteit foar betroubere prestaasjes |

DIN86044 flanges are fully compatible with seawater, allowing for the safe and efficient transportation of seawater in desalination plants, marine cooling systems, and other applications where contact with seawater is inevitable. Their compatibility ensures consistent performance without compromising the integrity of the piping system. |

|

Precision engineering foar strakke tolerânsjes |

Precision is at the core of DIN86044 flange manufacturing. Cangzhou Yulong Steel Co., Ltd. utilizes advanced engineering techniques to achieve tight dimensional tolerances, ensuring that the flanges fit perfectly with other piping components. This precision minimizes the risk of leaks and enhances the overall reliability of the piping system. |

|

Gemak fan ynstallaasje mei ienfâldige ôfstimming en bolting |

Installing DIN86044 flanges is straightforward, thanks to their design that facilitates easy alignment and bolting. The standardized dimensions and hole patterns make it simple for installers to position and secure the flanges, reducing installation time and labor costs. |

Preparation for Measuring DIN86044 Flange

1.Gather the Right Tools: To measure din 86044 flange dimensions accurately, you need the appropriate measuring tools. Essential tools include a caliper for measuring thickness and diameter, a tape measure for larger dimensions, a micrometer for highly precise measurements, and a straightedge or level to check flatness. Ensure that all tools are calibrated and in good working condition before starting the measurement process.

2.Inspect the Flange: Before taking any measurements, thoroughly inspect the DIN86044 flange for any visible damage, such as cracks, bends, or deformation. A damaged flange may have altered dimensions, and using it in a piping system can lead to leaks or failures. If any damage is detected, it's advisable to replace the flange or consult with Cangzhou Yulong Steel Co., Ltd. for further guidance.

3.Refer to the Standard: Familiarize yourself with the din 86044 flange standard. This standard provides detailed specifications for all dimensions of the flange, including outer diameter, inner diameter, thickness, bolt hole diameter, and bolt hole circle diameter. Having a clear understanding of the standard ensures that you measure the correct dimensions and can accurately compare the measured values with the required specifications.

Step - by - Step Measurement of DIN 86044 Flange Dimensions

1.Outer Diameter (OD): Place the caliper or tape measure on the outermost edge of the DIN86044 flange and measure across the widest part to determine the outer diameter. Take multiple measurements at different points around the flange to ensure consistency. Any significant variation in the measurements may indicate an irregularly shaped flange, which could affect its performance.

2.Inner Diameter (ID): Insert the caliper into the central hole of the flange and measure the diameter of the opening. Similar to the outer diameter, take multiple measurements to ensure accuracy. The inner diameter is crucial as it determines the flow capacity of the piping system and the compatibility with other components, such as pipes and valves.

3.Flange Thickness: Use a caliper or micrometer to measure the thickness of the flange at several points, including the center and near the edges. The thickness of the flange affects its strength and ability to withstand pressure. Deviations from the specified thickness in the din 86044 flange standard can compromise the integrity of the connection.

4.Bolt Hole Diameter: Measure the diameter of each bolt hole using a caliper. Ensure that all bolt holes have the same diameter as specified in the standard. Inconsistent bolt hole diameters can make it difficult to install bolts properly, leading to an insecure connection.

5.Bolt Hole Circle Diameter (Bolt Circle): Measure the diameter of the imaginary circle that passes through the center of all the bolt holes. This measurement is critical for ensuring that the bolts are evenly spaced and that the flange can be properly aligned with other flanges during installation. Use a tape measure or a specialized tool designed for measuring bolt circle diameters.

Key Considerations for Measuring DIN86044 Flange

1.Measurement Accuracy: Accuracy is paramount when measuring din 86044 flange dimensions. Even small errors in measurement can lead to significant problems during installation and operation. Always double - check your measurements and use high - quality measuring tools. If possible, have a second person verify the measurements to ensure accuracy.

2.Surface Finish: The surface finish of the DIN86044 flange can affect the measurement. Rough or uneven surfaces may lead to inaccurate readings. If necessary, clean and smooth the surface of the flange before taking measurements. However, be careful not to damage the flange during the cleaning process.

3.Temperature and Environment: Temperature and environmental conditions can also impact the dimensions of the flange. Metals expand and contract with temperature changes, so it's best to measure the flange at a standard temperature, preferably room temperature. Avoid measuring the flange in extreme temperatures or in environments with high humidity or vibration, as these factors can affect the accuracy of the measurements.

DIN86044 Flange Measurement FAQS

Why is it important to measure DIN86044 Flange dimensions accurately?

Accurately measuring din 86044 flange dimensions is crucial because it ensures proper fitment with other piping components. Incorrect dimensions can lead to leaks, reduced system efficiency, and potential safety hazards. By adhering to the din 86044 flange standard and measuring accurately, you can ensure a secure and reliable connection in the piping system.

What should I do if the measured dimensions of a DIN86044 Flange do not match the standard?

If the measured dimensions of a DIN86044 flange do not match the din 86044 flange standard, first double - check your measurements to ensure accuracy. If the discrepancy persists, contact Cangzhou Yulong Steel Co., Ltd. They can provide technical support, help you determine if the flange is defective, and offer solutions such as replacement or further inspection.

Can I use regular measuring tools to measure DIN 86044 Flange dimensions?

While regular measuring tools like calipers and tape measures can be used to measure din 86044 flange dimensions, it's important to use high - quality, calibrated tools for accurate results. For highly precise measurements, specialized tools such as micrometers may be required. Using improper or uncalibrated tools can lead to inaccurate measurements and potential problems during installation.

How often should I measure DIN86044 Flange dimensions?

Measure DIN86044 flange dimensions whenever you receive new flanges to ensure they meet the din 86044 flange standard. Additionally, if the flanges have been subjected to harsh conditions, such as high pressure, extreme temperatures, or mechanical stress, it's advisable to measure their dimensions periodically to check for any changes or damage.

Does Cangzhou Yulong Steel Co., Ltd. provide support for DIN86044 Flange measurement?

Yes, Cangzhou Yulong Steel Co., Ltd. offers comprehensive support for DIN86044 flanges. This includes providing detailed product specifications based on the din 86044 flange standard, technical advice on measurement methods, and assistance in resolving any issues related to flange dimensions. Wholesalers can rely on the company's expertise to ensure that they supply high - quality, accurately dimensioned flanges to their customers.

As a wholesaler, equipping yourself and your customers with the knowledge of how to measure DIN86044 flange dimensions correctly is essential for success in the industrial piping market. Cangzhou Yulong Steel Co., Ltd.'s commitment to quality and adherence to the din 86044 flange standard make their DIN86044 flanges a reliable choice. Contact us today to discuss wholesale opportunities, request product catalogs, and partner with a trusted manufacturer in the industry.

Lêste nijs

-

ANSI 150P SS304 SO FLANGE

NijsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NijsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NijsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NijsApr.19,2024

-

SABS 1123 FLANGE

NijsJan.15,2025

-

DIN86044 PLATE FLANGE

NijsApr.19,2024

-

DIN2527 BLIND FLANGE

NijsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NijsApr.23,2024