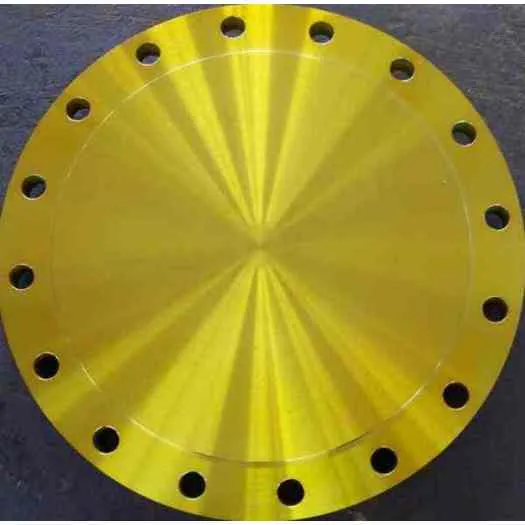

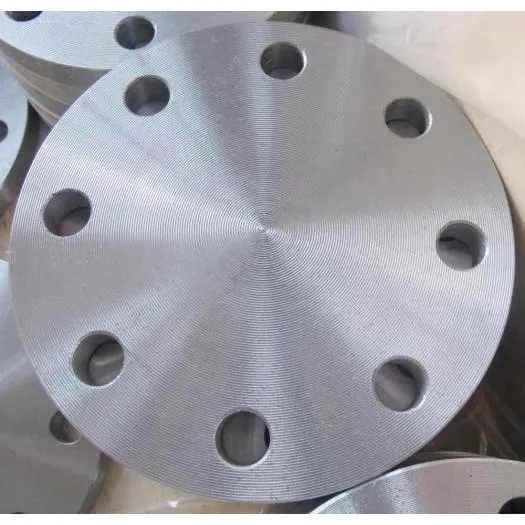

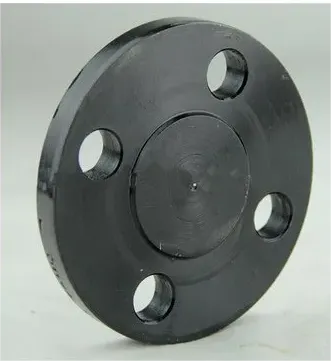

BS10 Blind flanges are commonly used in piping systems to close off the end of a pipe, valve, or equipment nozzle. The designation "Table D/E/F/H" refers to the pressure ratings and dimensions of these blind flanges according to the BS10 standard. Here is an introduction to the BS10 Blind flanges in each Table classification:

- 1.BS10 Blind Table D Flanges:

- - Table D blind flanges have lower pressure ratings compared to other tables.

- - These flanges are typically used in low-pressure applications to seal the end of piping systems.

- - Table D blind flanges conform to specific dimensions and drilling patterns as per the BS10 standard.

- - They provide a cost-effective and leak-proof solution for closing off piping systems.

- 2. BS10 Blind Table E Flanges:

- - Table E blind flanges have higher pressure ratings compared to Table D blinds.

- - These flanges are suitable for medium-pressure applications where a stronger seal is required.

- - Table E blind flanges are designed to provide a secure closure for piping systems.

- - They meet the dimensions and drilling specifications outlined in the BS10 standard.

- 3. BS10 Blind Table F Flanges:

- - Table F blind flanges have even higher pressure ratings than Table E blinds.

- - These flanges are used in systems that require a high level of pressure containment at the end of piping systems.

- - Table F blind flanges are designed to withstand more demanding operating conditions.

- - They adhere to specific dimensions and drilling patterns according to BS10 standards.

- 4. BS10 Blind Table H Flanges:

- - Table H blind flanges have the highest pressure ratings among the BS10 tables.

- - These flanges are employed in high-pressure applications where a strong and reliable seal is critical.

- - Table H blind flanges are engineered to handle extreme pressures and ensure a tight closure.

- - The dimensions and drilling specifications for Table H blind flanges are defined by the BS10 standard.

- In summary, BS10 Blind flanges in Tables D, E, F, and H offer varying pressure ratings and sealing capabilities, making them suitable for different pressure and temperature requirements in piping systems. These blind flanges provide an effective way to seal pipes, valves, or equipment nozzles in various industrial applications.

Sgrìobh do theachdaireachd an seo agus cuir thugainn e