-

Cangzhou Yulong Steel Co., Ltd.

-

Waya:

+86 13303177267 -

Imel:

admin@ylsteelfittings.com

- Turanci

- Larabci

- Italiyanci

- Mutanen Espanya

- Fotigal

- Jamusanci

- kazakh

- Farisa

- Girkanci

- Faransanci

- Rashanci

- Yaren mutanen Poland

- Thai

- Indonesiya

- Vietnamese

- Zulu

- Yaren Koriya

- Uzbek

- A'a

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawayi

- Ibrananci

- Miya

- Harshen Hungary

- Icelandic

- igbo

- Irish

- Jafananci

- Yawanci

- Kannada

- Khmer

- Ruwanda

- Afirka

- Albaniya

- Amharic

- Armenian

- Azabaijan

- Basque

- Belarushiyanci

- Bengali

- Bosniya

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estoniya

- Finnish

- Farisa

- Galiciyan

- Jojin

- Kurdish

- Kyrgyzstan

- TB

- Latin

- Latvia

- Lithuaniyanci

- Luxembourgish

- Makidoniya

- Malgashi

- Malayalam

- Maltase

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Yaren mutanen Norway

- Yaren mutanen Norway

- Occitan

- Pashto

- Yaren mutanen Holland

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Turanci

- Shona

- Sindhi

- Sinhala

- Slovak

- Sloveniya

- Somaliya

- Sundanci

- Harshen Swahili

- Yaren mutanen Sweden

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Baturke

- Turkmen

- Urdu

- Uighur

- Welsh

- Taimako

- Yadish

- Yarbawa

Jun . 27, 2025 11:22 Komawa zuwa lissafi

Insulation Steel Pipe: How FBE Coating & Glass Wool Conquer Strong Acid Soil Corrosion Through Integrated Design

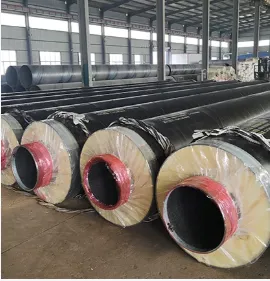

In underground piping systems menaced by strong acid soil corrosion and thermal loss, YULONG Steel’s insulation steel pipe emerges as a pioneering solution. Combining Fusible Bonded Epoxy (FBE) coating with glass wool insulation, this integrated design resolves dual challenges—corrosion and heat dissipation—making it ideal for chemical plants, oil fields, and urban infrastructure. As a leading pipe manufacturer, YULONG crafts these pipes to withstand pH <4 soils while optimizing thermal efficiency.

Dual Protection of Insulation Steel Pipe: FBE Coating & Glass Wool Synergy

1. FBE Coating: Molecular-Level Corrosion Resistance

YULONG’s 300–500μm FBE coating bonds chemically with steel, forming an impermeable barrier:

- Acid Resistance: In pH 3.5 soil, FBE-coated insulation steel pipes showed no corrosion after 10 years, outlasting bare steel by 8+ years. Electrochemical tests confirm its 10⁹ Ω·cm² polarization resistance, blocking H+ ion penetration.

- Adhesion & Durability: Baked at 200°C, the coating resists cathodic disbondment (≥50 N/cm peel strength), maintaining integrity during soil shifts or seismic activity, critical for Sichuan gas field pipelines.

2. Glass Wool Insulation: Thermal Stability with Corrosion Compatibility

The 50–150mm glass wool layer (λ=0.032 W/m·K) offers dual benefits:

- Heat Retention: Reduces steam loss by 85% in buried pipes, as seen in Beijing’s district heating, saving 15,000 tons of steam annually.

- Non-Degrading Design: Alkali-free composition avoids ion leaching, preserving FBE performance. In Shanghai wastewater plants, this synergy prevented corrosion for 8+ years.

Insulation Steel Pipe: Engineered Integration for Lasting Performance

1. Precision Surface Preparation

- 5 Blast Cleaning: Creates 50–80μm roughness, enhancing FBE adhesion by 30% versus lower-grade methods.

- Dehumidification: Ensures <40% RH to prevent undercoating rust, vital for high-humidity acidic environments.

Layered Defense Architecture

Steel substrate → FBE coating → glass wool → polyethylene jacket:

- Chemical & Physical Resistance: FBE withstands organic/mineral acids, while the jacket protects against abrasion. Yunnan phosphate mines used this design to operate flawlessly for 6 years in pH 2.8 soil.

- Thermal Consistency: Hydrophobic glass wool (water absorption <5%) maintains 90% thermal efficiency after 5,000 hours of water immersion.

Insulation Steel Pipe: Real-World Excellence in Harsh Conditions

1. Petrochemical & Urban Applications

- Zhejiang Refinery: FBE+glass wool pipes outlasted stainless steel+rock wool by 2.5x in pH 3.2 wastewater, cutting maintenance costs by 60%.

- Chongqing Metro: Met CJJ/T 81 standards with 75% less heat loss in steam lines, thanks to FBE’s 1,000-hour salt spray resistance and glass wool’s thermal stability.

YULONG: Your Trusted Partner for Insulation Steel Pipe

As a reliable pipe manufacturer offering insulation steel pipe for sale:

1. Custom Solutions for Diverse Needs

- Tailored Thickness: FBE (300–1,000μm) and glass wool (25–200mm) optimized for soil pH and temperature, like 800μm FBE for Guizhou’s pH 2.5 mining soil.

- Global Compliance: Meets API 5L, ISO 9001, and GB/T 29047, ensuring seamless integration in international projects.

2. Efficient Procurement & Support

- Rapid Delivery: DN25–DN1,200 sizes in stock across global warehouses, reducing Guangxi power plant downtime by 72 hours.

- Technical Expertise: Free corrosion risk assessments and thermal modeling help clients like Shandong chemical plants select optimal solutions when they buy metal pipe.

YULONG’s insulation steel pipe combines FBE’s corrosion resistance with glass wool’s thermal efficiency, delivering a unified solution for acidic soil environments. As a proven pipe manufacturer, we empower industries to overcome harsh conditions while optimizing energy use.

Choose YULONG for insulation steel pipe for sale that ensures decades of reliable performance. Contact us today to explore how our integrated design can safeguard your infrastructure and discover why we’re the preferred choice when you buy metal pipe.

Sabbin labarai

-

ANSI 150P SS304 SO FLANGE

LabaraiFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

LabaraiJan.20,2025

-

ANSI B16.5 welding wuyansa Flange

LabaraiJan.15,2026

-

ANSI B16.5 Slip-ON Flange

LabaraiApr.19,2024

-

SABS 1123 FLANGE

LabaraiJan.15,2025

-

DIN86044 FLANGE

LabaraiApr.19,2024

-

DIN2527 BLIND FLANGE

LabaraiApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

LabaraiApr.23,2024