-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

יונ . 03, 2025 03:00 Back to list

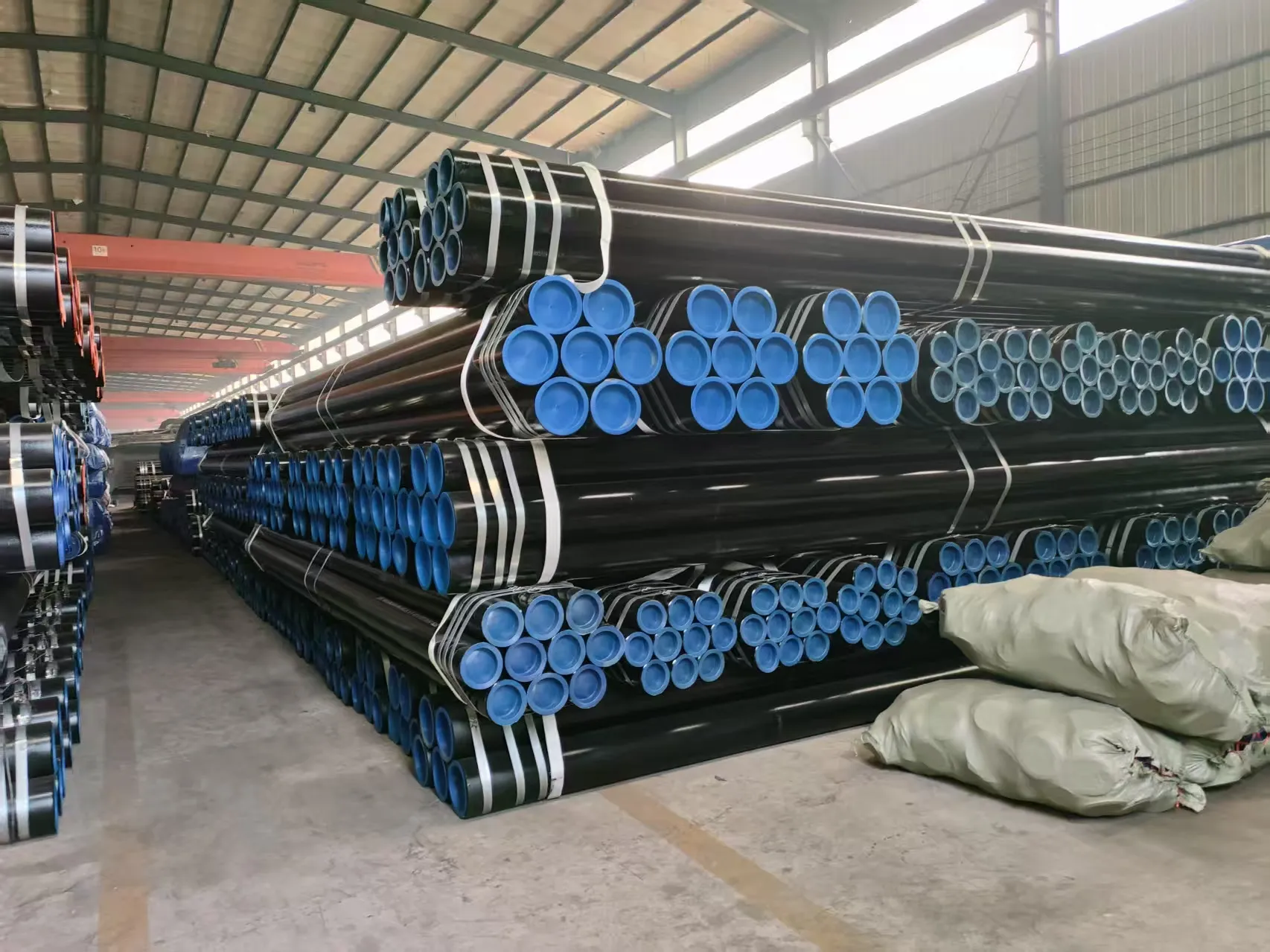

Premium Seamless Tubes & Pipes Manufacturers Custom Solutions

- Global market overview and key application sectors

- Material science and production technology advances

- Leading manufacturers comparison: capabilities analysis

- Engineering advantages over welded alternatives

- Material-specific performance: SS 410 spotlight

- Customization processes for specialized requirements

- Real-world implementation case studies

(seamless tubes and pipes manufacturers)

Global Leaders in Seamless Tubes and Pipes Manufacturing

The global market for precision-engineered seamless tubing solutions exceeds $80 billion annually, growing at 6.2% CAGR. Leading seamless tubes and pipes manufacturers

serve critical sectors including power generation (32% market share), oil & gas extraction (28%), and aerospace (19%). This dominance stems from continuous innovation in extrusion and pilgering technologies that enhance product integrity. For industries requiring absolute reliability under extreme pressure and temperature conditions – such as deepwater drilling operations exceeding 15,000 PSI – the structural uniformity provided by premium manufacturers prevents catastrophic failure points. Material traceability protocols maintained by certified producers ensure compliance with ASME B36.19M standards throughout the product lifecycle.

Advanced Manufacturing Methodologies Explained

Modern seamless pipe production employs three principal techniques: rotary piercing (58% of production), extrusion (32%), and plug rolling (10%). State-of-the-art facilities utilize computer-controlled mandrel mills that achieve dimensional tolerances within ±0.5% of specified wall thickness. Recent innovations include on-line ultrasonic testing systems capable of detecting micron-scale imperfections at production speeds of 40 meters/minute. Thermal treatment processes like normalizing and quenching enhance crystalline structures, with leading producers achieving tensile strengths exceeding 515 MPa in carbon steel alloys. Post-manufacturing processes include advanced NDT validation including eddy current testing and hydrostatic pressure verification at 150% of rated working pressure.

Technical Capabilities Comparison

| Manufacturer | Max OD (mm) | Wall Tolerance | Material Grades | Certifications | Lead Time |

|---|---|---|---|---|---|

| Specialty Tubes Ltd | 457 | ±5% | ASTM A106, A333, 4130 | PED, NORSOK | 8 weeks |

| Global Seamless Solutions | 610 | ±7% | API 5L, A335 P91, 316L | ASME III, ISO 9001 | 12 weeks |

| Precision Tube Group | 219 | ±3% | Inconel 625, SS 410, Duplex | AD2000, TÜV | 6 weeks |

Technical capability benchmarks show significant divergence in specialization areas – Precision Tube's tight tolerance focus contrasts with Global Seamless Solutions' large-diameter expertise. Material certifications directly impact suitability for chemical processing versus structural applications.

Performance Advantages Over Welded Alternatives

Seamless configurations demonstrate 23% higher burst pressure ratings and superior corrosion resistance in comparative testing. The absence of weld seams eliminates vulnerability zones where 89% of pipeline failures initiate. Mechanical properties show 15-30% greater consistency across the entire product length, critically important for high-cycle fatigue applications like hydraulic systems. Seamless tubes withstand wider temperature extremes (–196°C to 850°C) without compromising structural integrity. This reliability premium justifies the 18-25% cost differential in mission-critical applications, preventing unscheduled downtime costing up to $500,000/hour in refinery operations.

SS 410 Seamless Tubes: Technical Specifications

Martensitic stainless steel SS 410 seamless tubes offer optimal cost/performance characteristics with 11.5-13.5% chromium content. Key properties include:

- Yield strength: 415 MPa (min)

- Hardness: 217 HB (annealed condition)

- Corrosion resistance: Moderate (superior to carbon steel)

- Temperature range: –40°C to 650°C

These tubes undergo solution annealing at 815-900°C followed by controlled cooling to achieve optimal microstructure. Production incorporates strict sulfur content control (<0.025%) to prevent hot cracking during forming processes. Common applications include heat exchanger bundles, steam tubing, and fossil fuel processing components requiring moderate corrosion resistance with high strength.

Customization Capabilities

Premium seamless tubes and pipes manufacturers offer comprehensive engineering solutions including:

- Material development: Alloy modifications enhancing corrosion resistance by 40%

- Geometry specialization: Oval, square, and custom profiles beyond standard ASME sizes

- Surface enhancement: Bead-blasting, pickling, and passivation treatments

- End-finishing: Threading per API 5CT standards

The bespoke production process initiates with computational fluid dynamics modeling to predict material behavior, followed by prototype development using scaled-down pilger mills. Custom heat treatment protocols using computer-controlled atmosphere furnaces achieve specific grain structure requirements. Manufacturers maintain proprietary databases documenting the effects of 37 different process variables on final product characteristics.

Proven Implementations Across Industries

In offshore platforms, 316L seamless tubes with 8mm wall thickness successfully withstood 15 years of seawater corrosion in splash zones without perforation. Power transmission projects utilizing A335 P91 seamless pipes achieved 31% efficiency gains in supercritical steam applications at 625°C. Aerospace manufacturers reduced component weight by 18% using thin-walled titanium alloy seamless tubing validated to MIL-T-9046 standards. Chemical processing plants report zero failure incidents in high-pressure chlorine injection systems using specialized duplex seamless pipes over seven years of continuous operation. These implementations consistently validate the technical superiority offered by premium seamless tubes and pipes manufacturers across extreme operating environments.

(seamless tubes and pipes manufacturers)

FAQS on seamless tubes and pipes manufacturers

Q: What are the key advantages of seamless tubes and pipes compared to welded alternatives?

A: Seamless tubes and pipes offer superior strength and reliability due to the absence of weld seams, minimizing weak points. They provide better pressure containment and corrosion resistance, making them ideal for critical applications. Their uniform structure allows for consistent performance in high-stress environments.

Q: Which industries commonly use seamless pipes and tubes?

A: Major industries include oil & gas for drilling and pipelines, power generation for boiler systems, and automotive for fuel injection. Chemical processing plants utilize them for corrosive fluid transport, while aerospace relies on them for hydraulic systems and structural components.

Q: What are the specific properties of SS 410 seamless tubes?

A: SS 410 seamless tubes provide excellent corrosion resistance and high-temperature strength (up to 650°C). They offer good machinability and heat-treatable hardness for wear-resistant applications. These martensitic stainless steel tubes are commonly used in valves, shafts, and fossil fuel systems.

Q: How do reputable seamless tubes and pipes manufacturers ensure product quality?

A: Top manufacturers implement strict quality control including ultrasonic testing and hydrostatic pressure checks. They adhere to international standards like ASTM/ASME and provide material traceability certificates. Advanced facilities maintain precise dimensional tolerances through rotary piercing and cold drawing processes.

Q: What customization options do seamless tubes and pipes manufacturers typically offer?

A: Manufacturers can customize dimensions (OD from 1/8" to 24"), thickness schedules, and lengths according to specifications. Material variations include carbon steel, stainless grades like 304/316, and alloy steels. Additional services involve heat treatments, special coatings, threading, and precise cutting.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024