-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

márc . 05, 2025 02:32 Back to list

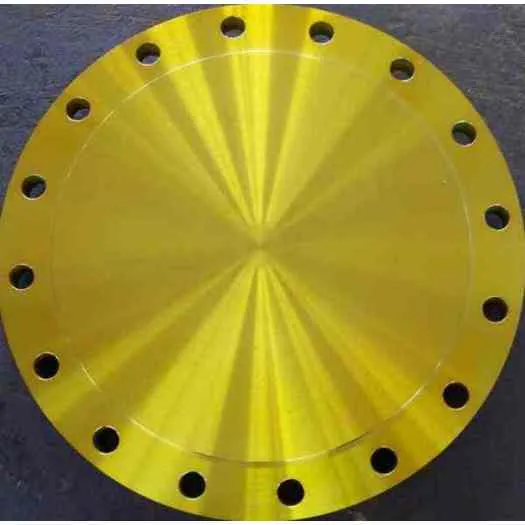

1 flange

Blind flanges, commonly abbreviated as BL flanges, serve a crucial role in the world of piping systems, offering a vital component that ensures safety, functionality, and ease of maintenance. As an industry specialist with years of experience in fittings and flanges, I’ll take you through the nuances of BL flanges, establishing why they are indispensable in industrial applications and how they contribute to the broader system design.

Another crucial aspect of blind flanges' utility is their role in system modifications and expansions. Industrial systems frequently require modifications due to expanding operational demands or the integration of new technologies. BL flanges afford designers and engineers the flexibility to restructure or extend systems efficiently. By simply removing a blind flange, new sections of pipeline can be added or redesigned with minimal disruption to the existing system. This flexibility highlights their value in dynamic industrial landscapes where agility and adaptability are keys to maintaining competitiveness. In terms of compliance and safety, blind flanges are designed to meet rigorous industry standards. Organizations like the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) set stringent guidelines that these components must satisfy. BL flanges adhere to these standards, providing assurances of safety, performance, and reliability. Industries around the globe rely on these standards to ensure that the components used in their systems will operate as intended, safeguarding both personnel and equipment. Furthermore, the integration of smart technologies with BL flanges is a growing trend that cannot be overlooked. Incorporating sensors and IoT technologies into flange systems provides real-time data on pressure changes, potential leakage, and structural integrity. This proactive approach to monitoring enhances trustworthiness and operational safety, allowing for immediate address of issues before they escalate into more significant problems. In conclusion, BL flanges are more than mere components of industrial pipeline systems; they are pivotal in ensuring the functionality, safety, and adaptability of modern industrial operations. Their role spans from providing reliability in system design and ease during maintenance to facilitating system expansions and embracing smart technology advancements. As industry demands evolve, so too will the innovations surrounding blind flanges, continually enhancing their efficacy and application scope. Through rigorous material selection, adherence to safety standards, and adaptation to modern technological advancements, blind flanges remain indispensable in industrial strategies that prioritize safety, efficiency, and longevity.

Another crucial aspect of blind flanges' utility is their role in system modifications and expansions. Industrial systems frequently require modifications due to expanding operational demands or the integration of new technologies. BL flanges afford designers and engineers the flexibility to restructure or extend systems efficiently. By simply removing a blind flange, new sections of pipeline can be added or redesigned with minimal disruption to the existing system. This flexibility highlights their value in dynamic industrial landscapes where agility and adaptability are keys to maintaining competitiveness. In terms of compliance and safety, blind flanges are designed to meet rigorous industry standards. Organizations like the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) set stringent guidelines that these components must satisfy. BL flanges adhere to these standards, providing assurances of safety, performance, and reliability. Industries around the globe rely on these standards to ensure that the components used in their systems will operate as intended, safeguarding both personnel and equipment. Furthermore, the integration of smart technologies with BL flanges is a growing trend that cannot be overlooked. Incorporating sensors and IoT technologies into flange systems provides real-time data on pressure changes, potential leakage, and structural integrity. This proactive approach to monitoring enhances trustworthiness and operational safety, allowing for immediate address of issues before they escalate into more significant problems. In conclusion, BL flanges are more than mere components of industrial pipeline systems; they are pivotal in ensuring the functionality, safety, and adaptability of modern industrial operations. Their role spans from providing reliability in system design and ease during maintenance to facilitating system expansions and embracing smart technology advancements. As industry demands evolve, so too will the innovations surrounding blind flanges, continually enhancing their efficacy and application scope. Through rigorous material selection, adherence to safety standards, and adaptation to modern technological advancements, blind flanges remain indispensable in industrial strategies that prioritize safety, efficiency, and longevity.

Next:

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024