-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

febr . 18, 2025 08:14 Back to list

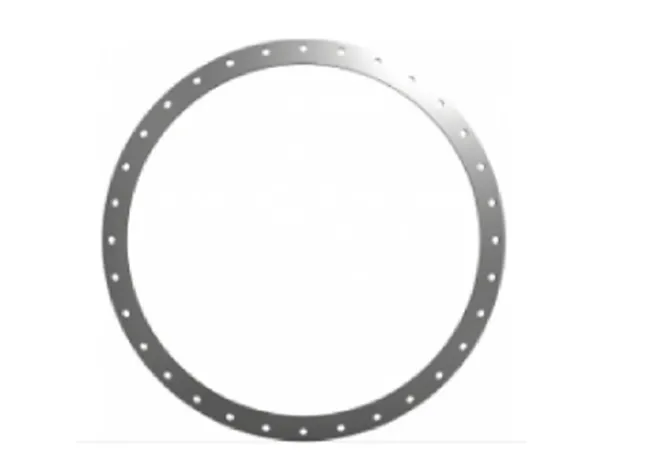

din 2527 blind flange

When it comes to industrial piping and mechanical systems, the choice of components plays a crucial role in ensuring longevity, safety, and efficiency. Among these essential components, flanges are pivotal, facilitating a seamless connection between pipes, valves, pumps, and other equipment. Particularly, DIN 16 flanges stand out in various industries due to their robustness, precision engineering, and adherence to German standards, making them a reliable choice for professionals worldwide.

Authoritativeness is reinforced when considering the engineering precision involved in manufacturing DIN 16 flanges. These flanges are crafted with meticulous attention to detail, ensuring perfect dimensions that allow for optimal alignment and secure connections in various piping systems. This precision minimizes the risk of leaks, ensuring a safe and efficient flow of contents through the pipeline. Additionally, the availability of different types of DIN 16 flanges — such as slip-on, blind, or weld neck flanges — provides flexibility to match the specific design and function requirements of a piping system. Trustworthiness and reliability are critical components of any industrial system. DIN 16 flanges are a testament to German engineering's reputation for producing durable and high-performance products. Industries that depend on continuous and safe operations can trust these flanges to deliver consistent performance under various operating conditions. The rigorous testing and quality control processes involved in the manufacture and certification of these flanges add another layer of assurance, providing stakeholders with peace of mind about their investment. Finally, the integration of DIN 16 flanges into any piping system is complemented by comprehensive documentation and technical support from manufacturers, allowing for seamless installation and maintenance. Access to detailed technical specifications, installation guides, and material certificates reflects the commitment of manufacturers to uphold the principles of trust and quality assurance, further solidifying their position as a reliable partner in industrial operations. In conclusion, the decision to utilize DIN 16 flanges in industrial applications is backed by a wealth of experience, expertise, and a commitment to quality and safety. Their engineering precision, material selection, and compliance with international standards highlight their indispensability in achieving efficient, safe, and long-lasting piping solutions. For businesses aiming to optimize their mechanical systems while minimizing risks, DIN 16 flanges undoubtedly represent a smart and strategic choice.

Authoritativeness is reinforced when considering the engineering precision involved in manufacturing DIN 16 flanges. These flanges are crafted with meticulous attention to detail, ensuring perfect dimensions that allow for optimal alignment and secure connections in various piping systems. This precision minimizes the risk of leaks, ensuring a safe and efficient flow of contents through the pipeline. Additionally, the availability of different types of DIN 16 flanges — such as slip-on, blind, or weld neck flanges — provides flexibility to match the specific design and function requirements of a piping system. Trustworthiness and reliability are critical components of any industrial system. DIN 16 flanges are a testament to German engineering's reputation for producing durable and high-performance products. Industries that depend on continuous and safe operations can trust these flanges to deliver consistent performance under various operating conditions. The rigorous testing and quality control processes involved in the manufacture and certification of these flanges add another layer of assurance, providing stakeholders with peace of mind about their investment. Finally, the integration of DIN 16 flanges into any piping system is complemented by comprehensive documentation and technical support from manufacturers, allowing for seamless installation and maintenance. Access to detailed technical specifications, installation guides, and material certificates reflects the commitment of manufacturers to uphold the principles of trust and quality assurance, further solidifying their position as a reliable partner in industrial operations. In conclusion, the decision to utilize DIN 16 flanges in industrial applications is backed by a wealth of experience, expertise, and a commitment to quality and safety. Their engineering precision, material selection, and compliance with international standards highlight their indispensability in achieving efficient, safe, and long-lasting piping solutions. For businesses aiming to optimize their mechanical systems while minimizing risks, DIN 16 flanges undoubtedly represent a smart and strategic choice.

Next:

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024