-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

márc . 04, 2025 12:13 Back to list

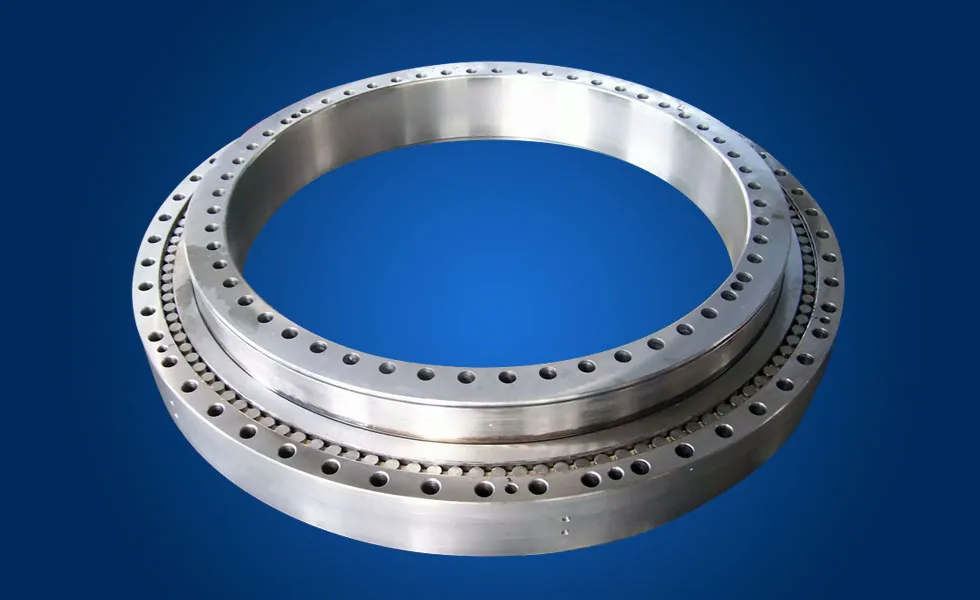

DIN2566 HUBBED THREAD FLANGE

The EN 1092-1 flange standard is a critical benchmark within the realm of industrial applications, guiding the design, manufacture, and application of flanges in various sectors. Flanges, though often underestimated, play a pivotal role in connecting pipes, valves, pumps, and other equipment, providing easy access for cleaning, inspection, or modification. The EN 1092-1 standard brings about uniformity and precision, crucial for industries globally to ensure safety, efficiency, and compatibility.

Trustworthiness, a pillar of this standard, lies in its robust development process and periodic updates, which incorporate the latest technological advancements and industry feedback. This process ensures that the EN 1092-1 remains relevant and reliable, addressing contemporary challenges faced by industries. Trust in this standard is not just placed by manufacturers but also by regulatory agencies, project managers, and end-users who rely on these flanges for the operational integrity of their systems. The ongoing evolution of EN 1092-1 fosters trust by continuously aiming to enhance safety, interoperability, and environmental considerations in industrial applications. As industries increasingly focus on sustainability, EN 1092-1 plays a crucial role in promoting environmentally sound practices. The standard's guidance on material selection extends to recommending corrosion-resistant and durable materials, thereby reducing the frequency of replacements and potential environmental harm. This aligns with the growing global emphasis on sustainable development, ensuring industries can meet current needs without compromising future generations. In conclusion, the EN 1092-1 flange standard is more than a mere set of guidelines; it is an embodiment of industrial precision, safety, and sustainability. The collective experience and expertise that feed into its continuous development make it a cornerstone of credible industrial practices. Its authority as a standard assures stakeholders of quality and safety, while the trust it garners ensures its application in critical environments. For any organization involved in the design, production, or application of flanges, adherence to EN 1092-1 is not just a beneficial practice but a necessary commitment to excellence and responsible stewardship.

Trustworthiness, a pillar of this standard, lies in its robust development process and periodic updates, which incorporate the latest technological advancements and industry feedback. This process ensures that the EN 1092-1 remains relevant and reliable, addressing contemporary challenges faced by industries. Trust in this standard is not just placed by manufacturers but also by regulatory agencies, project managers, and end-users who rely on these flanges for the operational integrity of their systems. The ongoing evolution of EN 1092-1 fosters trust by continuously aiming to enhance safety, interoperability, and environmental considerations in industrial applications. As industries increasingly focus on sustainability, EN 1092-1 plays a crucial role in promoting environmentally sound practices. The standard's guidance on material selection extends to recommending corrosion-resistant and durable materials, thereby reducing the frequency of replacements and potential environmental harm. This aligns with the growing global emphasis on sustainable development, ensuring industries can meet current needs without compromising future generations. In conclusion, the EN 1092-1 flange standard is more than a mere set of guidelines; it is an embodiment of industrial precision, safety, and sustainability. The collective experience and expertise that feed into its continuous development make it a cornerstone of credible industrial practices. Its authority as a standard assures stakeholders of quality and safety, while the trust it garners ensures its application in critical environments. For any organization involved in the design, production, or application of flanges, adherence to EN 1092-1 is not just a beneficial practice but a necessary commitment to excellence and responsible stewardship.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024