-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

márc . 04, 2025 11:04 Back to list

DIN2566 HUBBED THREAD FLANGE

Flange dimensions according to EN 1092-1 are critical for ensuring compatibility and safety in various industrial applications. This European standard specifies the requirements for circular steel flanges, designed not only to connect pipes, valves, or other machinery but also to maintain the integrity and safety of a given system under various pressure conditions.

When implementing flanges that adhere to EN 1092-1, the expertise of experienced engineers or technical consultants is invaluable. Their insights can guide the selection process, ensuring that the right flange type and specifications are chosen for specific applications. High-quality manufacturing, combined with rigorous inspection processes, guarantees that the flanges meet the stringent requirements of EN 1092-1. Additionally, the installation of these flanges must be handled by trained professionals. Proper torque application, alignment, and the use of suitable gaskets are vital to achieving optimal performance and preventing leaks. Regular maintenance checks and inspections are also recommended to address any wear or damage that may occur over time, maintaining the system’s integrity and performance. The authority of EN 1092-1 as a standard ensures that products manufactured according to its specifications are globally recognized and trusted. This standardization alleviates concerns over compatibility and performance, allowing for seamless integration across different components and systems worldwide. It serves as a benchmark for quality and safety, reassuring stakeholders of the product's reliability. To build and sustain trust in flange applications, suppliers and manufacturers often seek certifications that validate their adherence to EN 1092-1. These certifications, issued by reputable third-party auditing organizations, serve as an assurance of compliance and quality. Clients should prioritize working with certified suppliers to ensure that the products they receive meet or exceed industry standards, reducing the risk of system failure or non-compliance with regulations. The comprehensive understanding of flange dimensions as per EN 1092-1 reflects a commitment to excellence and safety in engineering practices. Professionals equipped with this knowledge are better prepared to design, select, and implement flanged connections that stand the test of time, providing confidence to industries relying on safe, efficient piping systems. By aligning with these standards, companies ensure that they meet the expectations of quality and precision that modern industries demand.

When implementing flanges that adhere to EN 1092-1, the expertise of experienced engineers or technical consultants is invaluable. Their insights can guide the selection process, ensuring that the right flange type and specifications are chosen for specific applications. High-quality manufacturing, combined with rigorous inspection processes, guarantees that the flanges meet the stringent requirements of EN 1092-1. Additionally, the installation of these flanges must be handled by trained professionals. Proper torque application, alignment, and the use of suitable gaskets are vital to achieving optimal performance and preventing leaks. Regular maintenance checks and inspections are also recommended to address any wear or damage that may occur over time, maintaining the system’s integrity and performance. The authority of EN 1092-1 as a standard ensures that products manufactured according to its specifications are globally recognized and trusted. This standardization alleviates concerns over compatibility and performance, allowing for seamless integration across different components and systems worldwide. It serves as a benchmark for quality and safety, reassuring stakeholders of the product's reliability. To build and sustain trust in flange applications, suppliers and manufacturers often seek certifications that validate their adherence to EN 1092-1. These certifications, issued by reputable third-party auditing organizations, serve as an assurance of compliance and quality. Clients should prioritize working with certified suppliers to ensure that the products they receive meet or exceed industry standards, reducing the risk of system failure or non-compliance with regulations. The comprehensive understanding of flange dimensions as per EN 1092-1 reflects a commitment to excellence and safety in engineering practices. Professionals equipped with this knowledge are better prepared to design, select, and implement flanged connections that stand the test of time, providing confidence to industries relying on safe, efficient piping systems. By aligning with these standards, companies ensure that they meet the expectations of quality and precision that modern industries demand.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

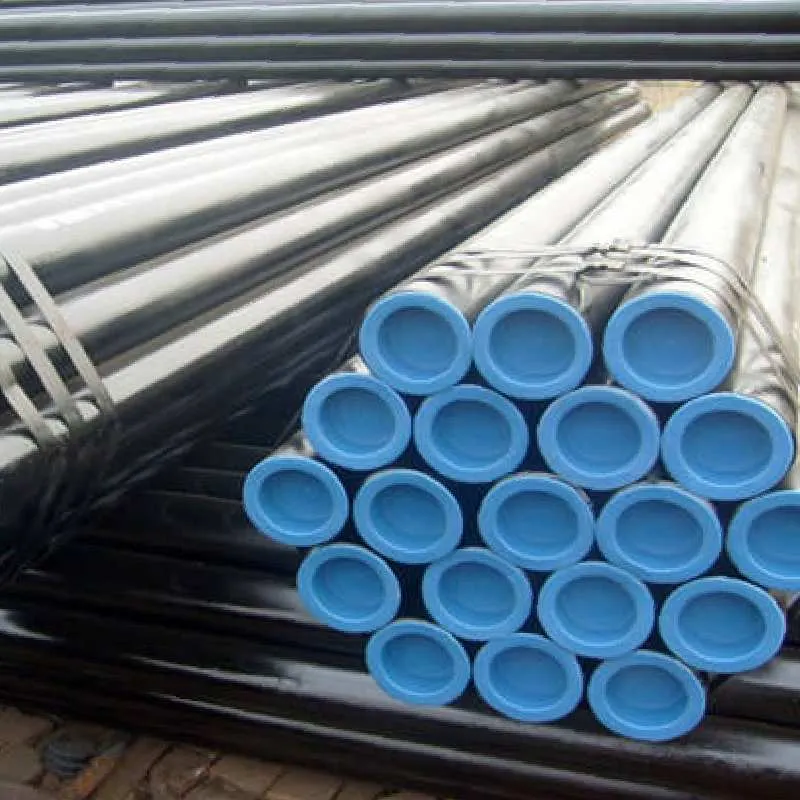

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024