Standard Specifications

BS4504 is the British pipe flange standard, which specifies the size, pressure level, material, manufacturing process and test method of the flange, ensuring the quality and interchangeability of the flange in different engineering projects.

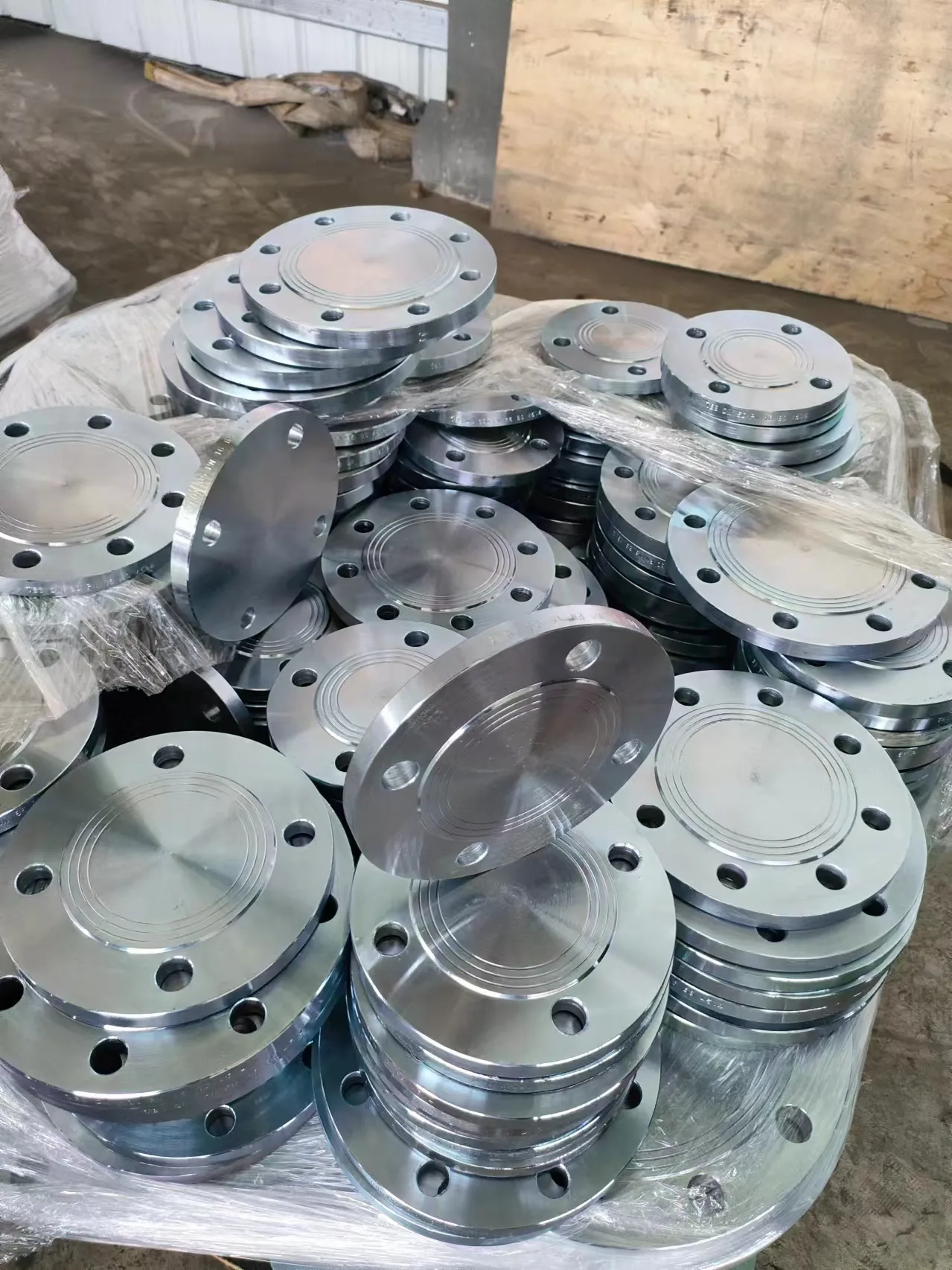

Structural Features

Blind flange structure: The blind flange is a disc-shaped component with no through hole in the middle and bolt holes evenly distributed on the circumference. It is used to block the end of the pipeline or equipment, play a sealing and isolation role, and can effectively prevent medium leakage and ensure the safety and integrity of the system.

Cold galvanizing coating: Cold galvanizing is to apply a zinc-rich coating on the flange surface through a specific process at room temperature to form an isolation layer, protect the flange base metal from corrosion from the external environment, have good corrosion resistance, and relatively low cost.

Size Specifications

Nominal diameter: usually covers DN10 to DN600 or even larger, depending on the diameter of the connected pipe or equipment.

Pressure level: There are different pressure levels such as PN6, PN10, PN16, PN25, PN40, etc., which determine the maximum pressure that the blind flange can withstand.

Material selection

Base material: Common ones are carbon steel and stainless steel. Carbon steel such as S235JR has good strength and processing performance, low cost, and is widely used in general industry; stainless steel such as 304 and 316 has excellent corrosion resistance and mechanical properties, and is suitable for harsh environments such as chemical, food, and medicine.

Galvanized material: The main material of cold galvanizing is zinc-rich coatings, etc., which use the electrochemical protection of zinc to provide good corrosion resistance for flanges.

Application field

Electrical/Cold galvanized: In electrical systems, it is used for end sealing of electrical pipelines to prevent dust, moisture, etc. from entering the pipelines, affecting the normal operation of electrical equipment, and ensuring the safety and stability of electrical systems.

Chemical industry: In chemical production, it is used in chemical pipeline systems. During equipment inspection and maintenance, it isolates dangerous or corrosive media in the pipeline to ensure inspection safety. It can also be used for temporary blocking of pipelines.

Water treatment industry: In the pipeline system of a water treatment plant, it can be used to isolate pipelines of different treatment units, which is convenient for equipment maintenance and pipeline cleaning. The cold galvanized layer can effectively resist water corrosion and extend the service life of the flange.

-

Cangzhou Yulong Steel Co., Ltd.

-

Sími:

+86 13303177267 -

Netfang:

admin@ylsteelfittings.com

- Enska

- arabíska

- ítalska

- spænska, spænskt

- portúgalska

- þýska, Þjóðverji, þýskur

- kasakska

- persneska

- grísku

- franska

- Rússneskt

- pólsku

- Tælensk

- indónesíska

- Víetnamska

- Zulu

- kóreska

- úsbekskur

- Neibb

- serbneska

- malaíska

- úkraínska

- Gújaratí

- Haítískt kreóla

- hausa

- hawaiískur

- hebreska

- Miaó

- ungverska, Ungverji, ungverskt

- íslenskur

- ígbó

- írska

- japönsku

- javanska

- Kannada

- Khmer

- Rúanda

- Afríku

- albanska

- amharíska

- Armenska

- Aserbaídsjan

- baskneska

- hvítrússneska

- bengalska

- bosníska

- búlgarska

- katalónska

- Cebuano

- Kína

- Kína (Taívan)

- korsíkanskt

- króatíska

- tékkneska

- danska

- esperantó

- eistneska, eisti, eistneskur

- finnska

- frísneska

- galisíska

- georgískt

- Kúrda

- Kirgisi

- TB

- latína

- lettneska

- litháískur

- Lúxemborg

- makedónska

- Malgashi

- Malajalam

- maltneska

- Maori

- Marathi

- mongólska

- Mjanmar

- nepalska

- norska

- norska

- Oksítanska

- Pastó

- hollenska

- Púndjabí

- rúmenska

- Samósk

- skosk gelíska

- Enska

- Shona

- Sindhi

- Sinhala

- slóvakíska

- slóvenska

- sómalska

- Sundaneskir

- svahílí

- sænsku

- Tagalog

- Tadsjikska

- tamílska

- Tatar

- Telúgú

- tyrkneska

- Túrkmena

- Úrdú

- Uighur

- velska

- Hjálp

- jiddíska

- Jórúba

Skrifaðu skilaboðin þín hér og sendu okkur

Related News

-

Jul . 23, 2025Space-Saving Connection Mastery: How 1/2 Pipe Nipple’s 50mm Short Design Solves Dense Piping Installation Challenges?In the labyrinth of industrial machinery, where pipes weave through 200mm-wide gaps and every millimeter counts, the battle against cramped spaces often stalls projects.

-

Jul . 23, 2025Shale Gas Extraction Impact Resistance: How ASME B16.47 Flange's Hub-Thickened Design Passes Seismic Testing?In the high-stakes realm of shale gas extraction, where seismic activity and operational vibrations threaten pipeline integrity, the ASME B16.47 flange emerges as a critical safeguard.