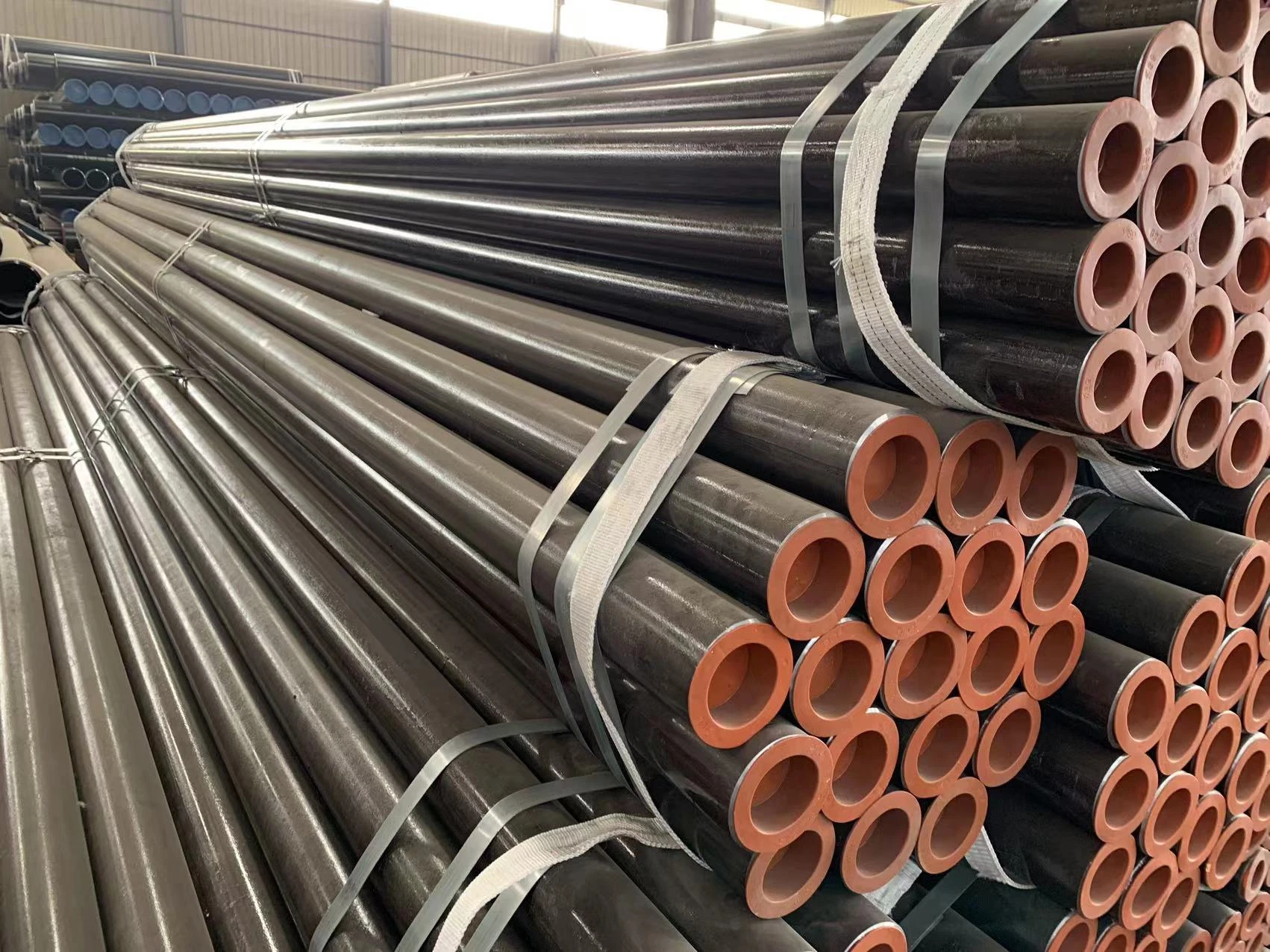

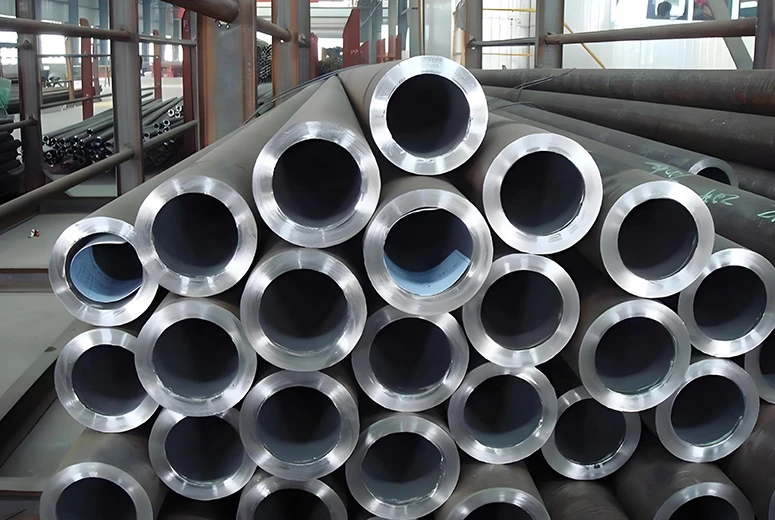

Api Seamless Steel Pipe

Seamless steel pipes are produced through rotary piercing or extrusion. First, a solid steel billet is heated and pierced to form a hollow shell. It is then rolled and stretched using a mandrel mill or plug mill to achieve the desired diameter and wall thickness. Further sizing and finishing ensure dimensional accuracy. Heat treatment enhances mechanical properties, followed by straightening, inspection, and testing. This process eliminates welds, creating pipes with uniform strength, ideal for high-pressure and high-temperature applications in industries like oil, gas, and power generation.