-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

មករា . 14, 2025 16:54 Back to list

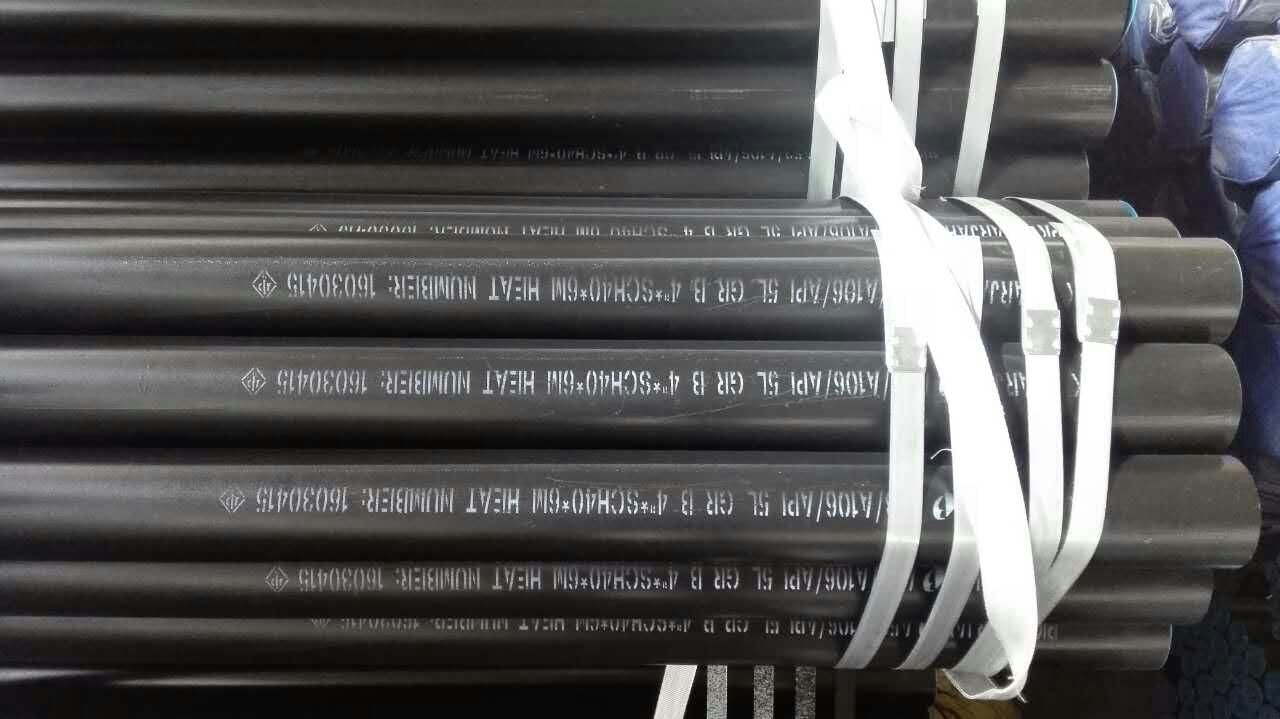

ASTM A106 Gr B Seamless Pipe

ASTM B705 seamlessly blends superior engineering with rigorous quality standards. Specializing in seamless nickel and nickel-alloy pipes and tubes, this specification is a benchmark in high-performance material engineering. Its predominant use in industries facing extreme environments underscores its esteemed stature for delivering unparalleled robustness and corrosion resistance.

Trust in ASTM B705 stems from its consistent performance outcomes backed by comprehensive materials research and stringent field testing. The specification garners widespread endorsement from construction managers and infrastructure stakeholders, who steadily regard it as an essential component in high-stakes applications where failure is not an option. To encapsulate the trustworthiness of ASTM B705, one must consider the rigorous certification processes it undergoes, including third-party testing that verifies its compositional integrity and mechanical properties. This layer of verification ensures compliance with global safety and quality benchmarks, reassuring stakeholders of its reliability. For project developers and procurement specialists, adopting ASTM B705 facilitates seamless alignment with both domestic and international industrial regulations. It minimizes the risk of non-compliance, thereby safeguarding project timelines and budgeting considerations. The specification’s homogeneous metallurgical properties translate into more predictable and manageable fabrication and installation procedures, often resulting in reduced manpower and time costs. In synthesis, ASTM B705 remains indispensable in the arsenal of materials engineered for high-performance applications. Its unparalleled established reputation is a testament to its adaptability and reliability across multifaceted industrial applications. This industry standard not only exemplifies the pinnacle of modern metallurgical engineering but also sets a template for future advancements in material science, ensuring continued trust and reliance for generations.

Trust in ASTM B705 stems from its consistent performance outcomes backed by comprehensive materials research and stringent field testing. The specification garners widespread endorsement from construction managers and infrastructure stakeholders, who steadily regard it as an essential component in high-stakes applications where failure is not an option. To encapsulate the trustworthiness of ASTM B705, one must consider the rigorous certification processes it undergoes, including third-party testing that verifies its compositional integrity and mechanical properties. This layer of verification ensures compliance with global safety and quality benchmarks, reassuring stakeholders of its reliability. For project developers and procurement specialists, adopting ASTM B705 facilitates seamless alignment with both domestic and international industrial regulations. It minimizes the risk of non-compliance, thereby safeguarding project timelines and budgeting considerations. The specification’s homogeneous metallurgical properties translate into more predictable and manageable fabrication and installation procedures, often resulting in reduced manpower and time costs. In synthesis, ASTM B705 remains indispensable in the arsenal of materials engineered for high-performance applications. Its unparalleled established reputation is a testament to its adaptability and reliability across multifaceted industrial applications. This industry standard not only exemplifies the pinnacle of modern metallurgical engineering but also sets a template for future advancements in material science, ensuring continued trust and reliance for generations.

Next:

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024