-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

ಸೆಪ್ಟೆಂ . 07, 2024 09:51 Back to list

ANSI Flanges Catalog - Quality Flange Solutions

Understanding ANSI Flanges A Comprehensive Overview

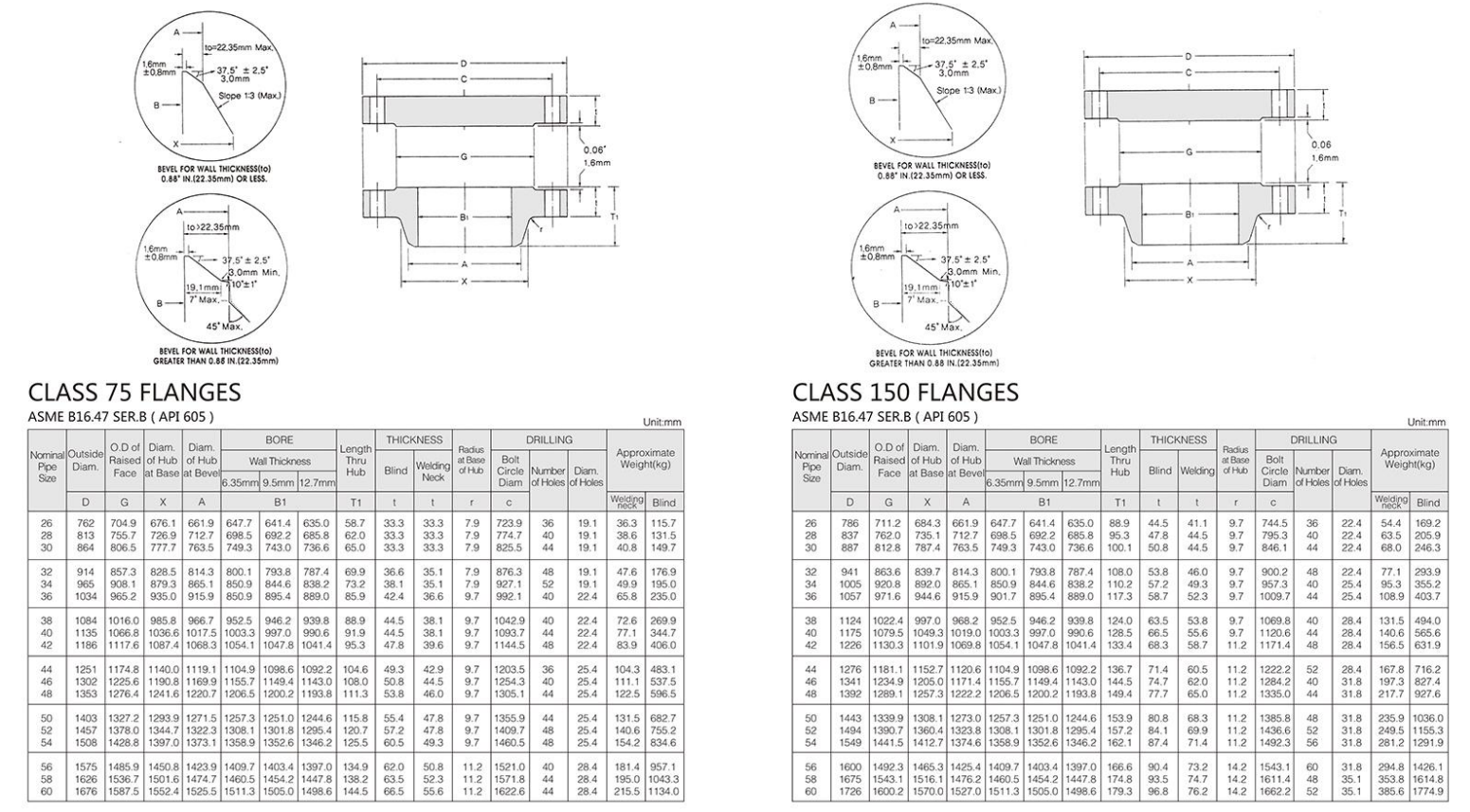

Flanges are critical components in piping systems, providing a means to connect pipes, valves, and various equipment. Among the various standards available for flanges, ANSI (American National Standards Institute) flanges are among the most widely used in industrial applications. This article explores the significance of ANSI flanges, their classification, and the benefits they offer.

Understanding ANSI Flanges A Comprehensive Overview

Flanges can be categorized into different types based on their design and application. The most common types of ANSI flanges include slip-on flanges, weld neck flanges, blind flanges, and threaded flanges. Slip-on flanges are easy to install, as they slide over the pipe’s end. Weld neck flanges, on the other hand, provide superior strength and are welded to the pipe, making them ideal for high-pressure applications. Blind flanges are utilized to seal the end of a pipeline, while threaded flanges are attached through a threaded connection, making them suitable for applications where welding is impractical.

catalogo flanges ansi

One of the significant advantages of using ANSI flanges is their ability to facilitate easy maintenance and inspection. By allowing sections of the piping system to be easily disconnected, ANSI flanges enable quick access to valves and equipment for repairs or replacements without the need for cutting pipes. This feature not only saves time and labor costs but also minimizes downtime in operational processes.

Moreover, ANSI flanges are compatible with a variety of materials, including carbon steel, stainless steel, and alloy steel. This versatility ensures that they can be utilized in diverse environments, from chemical processing and oil and gas to water treatment and power generation.

In conclusion, ANSI flanges play a vital role in piping systems across multiple industries. Their adherence to standardized specifications, variety of types, and ease of installation and maintenance make them an indispensable component for ensuring safe and efficient operations. Understanding the nuances of ANSI flanges can help professionals select the right type for their specific application, enhancing the overall performance and reliability of their piping systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024