ASME B16.47 is a standard developed by the American Society of Mechanical Engineers (ASME), titled "Large Diameter Steel Flanges (NPS 26 to NPS 60)". The standard contains two series, Series A is mainly in English units, and Series B uses metric units. ASME B16.47 Lap Joint Flange is a large diameter loose flange that meets this standard, which is often used for connecting large-diameter pipeline systems.

Structural features

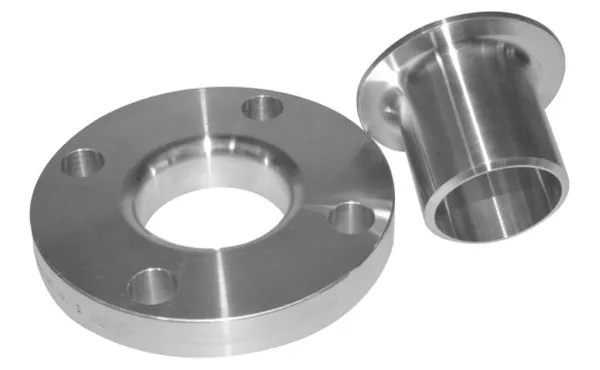

Flange body: The loose flange body is usually a ring, and its inner diameter is slightly larger than the outer diameter of the steel pipe it matches, generally 1-3mm larger. It is not directly welded to the pipeline, but loosely sleeved on the pipeline.

Flanged nipple: It needs to be used with a matching flanging nipple. One end of the flanging nipple is welded to the pipeline, and the welding method is generally fillet welding, and the weld quality requirements meet the relevant standards. The flanging part provides a flat surface for the sealing surface, and its shape and size are precisely manufactured according to the standard.

Sealing surface: Common sealing surface forms include raised face (RF), full plane (FF), etc. The raised face sealing surface has a certain height, and can achieve a better sealing effect when combined with the gasket; the full plane sealing surface has a flat surface, which is suitable for low pressure and occasions where the sealing requirements are not extremely high.

Material selection

Carbon steel: such as ASTM A105, has good strength and toughness, relatively low cost, suitable for general industrial pipeline systems, and can withstand certain pressure and temperature. Commonly used for the transportation of media such as water, steam, and air.

Stainless steel: such as ASTM A182 F304, F316 and other materials, with excellent corrosion resistance. Widely used in pipeline systems in chemical, food, pharmaceutical and other industries, it can prevent the corrosion of the flange by the medium and ensure the long-term stable operation of the pipeline system.

Alloy steel: Low-temperature alloy steel such as ASTM A350 LF2 can maintain good performance in low-temperature environments and is often used in low-temperature pipeline systems, such as the transportation of liquefied natural gas (LNG).

Manufacturing Process

Forging or rolling: The flange body is usually manufactured by forging or rolling. Forging can improve the material structure and increase the strength and toughness of the flange; rolling can improve production efficiency and dimensional accuracy.

Machining: The flange blank after forging or rolling is machined, including turning, drilling, milling and other processes to achieve the dimensional accuracy and surface quality required by the standard. The flanged short section also needs to go through a similar processing process.

Application Scenarios

Oil and Gas Industry

In the pipeline system of offshore oil platforms, large-diameter loose flanges are easy to install and disassemble, and are widely used in areas that require frequent inspection and maintenance.

At some branch nodes or valve connections of long-distance natural gas pipelines, the use of loose flanges can reduce the stress during pipeline installation and improve the reliability of the connection.

Chemical Industry

In the pipeline system of large chemical plants, due to the corrosive nature of the medium, the ASME B16.47 loose flange made of stainless steel can effectively prevent corrosion and ensure the safe operation of the system.

In some occasions where pipe parts need to be replaced frequently, the structural characteristics of the loose flange make the replacement process more convenient and reduce downtime.

Power Industry

In large-diameter pipeline systems such as circulating water pipelines and chemical water treatment pipelines in power plants, loose flanges can be used to connect different equipment and pipelines, facilitating installation and maintenance.