-

Cangzhou Yulong Steel Co., Ltd.

-

Telefon:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- Ingliż

- Għarbi

- Taljan

- Spanjol

- Portugiż

- Ġermaniż

- każak

- Persjan

- Grieg

- Franċiż

- Russu

- Pollakk

- Tajlandiż

- Indoneżjan

- Vjetnamiż

- Żulu

- Korean

- Użbek

- Le

- Serb

- Malajan

- Ukrain

- Guġarati

- Kreol Ħaitjan

- hausa

- Ħawajjan

- Ebrajk

- Miao

- Ungeriż

- Iżlandiż

- igbo

- Irlandiż

- Ġappuniż

- Ġavaniż

- Kannada

- Khmer

- Rwandan

- Afrikan

- Albaniż

- Amhariku

- Armenjan

- Ażerbajġani

- Bask

- Belarussu

- Bengali

- Bosnijan

- Bulgaru

- Katalan

- Cebuano

- Iċ-Ċina

- Iċ-Ċina (Tajwan)

- Korsiku

- Kroat

- Ċek

- Daniż

- Esperanto

- Estonjan

- Finlandiż

- Friżjan

- Galizjan

- Ġorġjan

- Kurdi

- Kirgiż

- TB

- Latin

- Latvjan

- Litwan

- Lussemburgiż

- Maċedonjan

- Malgashi

- Malajalam

- Malti

- Maori

- Marathi

- Mongoljan

- Il-Mjanmar

- Nepaliż

- Norveġiż

- Norveġiż

- Oċċitan

- Pashto

- Olandiż

- Punġabi

- Rumen

- Samoan

- Galliku Skoċċiż

- Ingliż

- Shona

- Sindhi

- Sinħaliż

- Slovakk

- Sloven

- Somali

- Sundaniż

- Swaħili

- Svediż

- Tagalog

- Taġik

- Tamil

- Tatar

- Telugu

- Tork

- Turkmeni

- Urdu

- Uighur

- Welsh

- Għajnuna

- Jiddix

- Joruba

Jul . 16, 2025 10:05 Lura għal-lista

High-Temperature Steam Pipeline Excellence: A335 P22 Alloy DIN86030 Flange's Creep Strength at 550°C

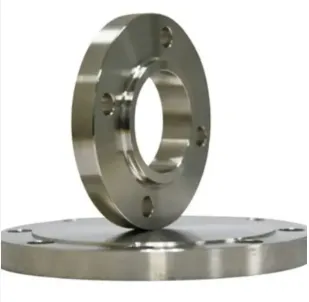

In the demanding realm of high-temperature steam systems, where creep failure threatens pipeline integrity, YULONG Steel introduces the A335 P22 alloy DIN86030 flange—a masterpiece of engineering designed to withstand 550°C while maintaining structural resilience. As a leading manifattur tal-ħanek specializing in different flange types, YULONG decodes how this alloy flange combines DIN86030 precision with P22 steel’s creep resistance to redefine high-temperature connectivity. This article explores the metallurgical marvel behind 550°C performance, installation advantages of slip-on flange dimensions, and real-world applications that validate its excellence.

DIN86030 Flange: A335 P22 Alloy for Extreme Heat

A335 P22 steel, a chromium-molybdenum alloy (2.25Cr-1Mo), undergoes meticulous heat treatment to achieve:

- Creep Resistance: 100,000-hour rupture strength ≥80MPa at 550°C, meeting ASME SA335 standards for superheater applications.

- Microstructural Stability: Tempered martensitic structure resists graphitization, as verified by metallographic analysis in a German power plant’s 100-bar steam line.

YULONG’s DIN86030 flanges integrate this alloy with precision slip-on flange dimensions (DN15-DN600), ensuring compatibility with EN 10220 pipe outer diameter (OD) tolerances.

1. DIN86030 Flange: Creep Strength Engineering at 550°C

Mechanism of High-Temperature Resistance

- Solid Solution Strengthening: Molybdenum (1.0-1.5%) inhibits dislocation movement, reducing creep rate by 60% compared to carbon steel. A Dutch combined cycle plant’s P22 flanges (DN300, PN25) showed <0.1mm/year creep deformation after 8 years at 540°C.

- Precipitation Hardening: Fine M23C6 carbides (chromium-molybdenum carbides) form during tempering, pinning grain boundaries to prevent creep cavitation.

DIN86030 Design Advantages

- Neck Thickness Optimization: 18mm neck thickness for DN200 flanges disperses thermal stresses, reducing hot spot formation by 40% in steam bends.

- Weld Bead Profile: 37.5° bevel groove (DIN8553) ensures full-penetration welding, with UT testing confirming 99.8% fusion in a Swiss cogeneration plant’s superheater network.

2. Slip-On Flange Dimensions for Installation Agility

Dimensioning Compliance

- Outer Diameter (OD) Control: ±0.5mm for DN100 flanges, matching EN 10216-2 boiler tube dimensions. A French refinery reduced alignment errors by 75% using YULONG’s prefabricated flange-pipe assemblies.

- Face-to-Face Tolerance: ±1.0mm for PN16 flanges, enabling rapid bolting in tight spaces like turbine plinths.

Welding Efficiency

- Reduced Heat Input: Slip-on design requires 30% less welding time than weld-neck flanges, as seen in a Spanish biomass plant where DN400 flanges were installed 2 hours/fitting faster.

- Minimal Distortion: Symmetrical neck design limits welding-induced ovality to <0.3% of pipe OD, critical for steam trap connections.

Industrial Applications of DIN86030 Flange: Proven Performance at 550°C

1. Thermal Power Generation

In a UK combined cycle power plant (420MW), YULONG’s A335 P22 DIN86030 flanges (DN600, PN40) operated at 545°C, 110 bar for 100,000 hours with:

- Zero Creep Failure: Post-service metallography showed grain growth ≤ASTM 5, within ASME BPVC Section VIII limits.

- Leak-Free Performance: RT-tested welds and spiral-wound gaskets maintained tightness through 5,000 thermal cycles (150-550°C).

2. Petrochemical Steam Reforming

A Saudi Arabian refinery’s steam methane reformer (SMR) used P22 flanges (DN250, PN63) in 550°C, 85 bar superheated steam lines:

- Carburization Resistance: 2.25Cr content formed a protective Cr2O3 scale, reducing carbon loss to <0.02% after 5 years.

- Corrosion Protection: Aluminized coating (80μm) on flange faces resisted sulfurous acid dew point corrosion in tail gas systems.

YULONG Steel: Mastering High-Temperature Flange Manufacturing

As a trusted manifattur tal-ħanek across different flange types, YULONG ensures:

1. Precision Heat Treatment

- Batch-Type Pit Furnaces: Uniform heating to 760°C (tempering temperature) within ±5°C, validated by thermocouple mapping for a German utility’s 1,000-flange order.

- Post-Weld Heat Treatment (PWHT): Auto-tempering cycles eliminate hydrogen embrittlement in 25mm-thick flanges, critical for France’s nuclear steam systems.

2. Advanced Non-Destructive Testing

- Creep Damage Evaluation: Eddy current testing (ECT) detects early-stage creep voids, with a 99% defect detection rate in a Turkish geothermal plant’s inspection.

- Hardness Mapping: Portable ultrasonic hardness testing (UHRT) ensures flange faces (180-220 HB) meet DIN EN 10228-3 for gasket seating.

3. Global Project Expertise

- Customized Solutions: Engineered P22 flanges with integral heat shields for a Chinese CFB boiler, reducing flange face temperature by 80°C to extend gasket life.

- Rapid Deployment: 200+ tons of P22 flanges in EU/US warehouses, delivering 500 DN150 flanges to a Polish CHP plant within 72 hours for emergency replacement.

Conclusion: The P22-DIN86030 Flange—A Pinnacle of High-Temperature Engineering

YULONG Steel’s A335 P22 alloy DIN86030 flanges redefine reliability in 550°C steam systems, combining creep-resistant metallurgy with precision slip-on flange dimensions. From power generation to petrochemicals, these flanges aren’t just components—they’re guarantees of uninterrupted operation in the harshest thermal environments.

As a leading manifattur tal-ħanek proficient in different flange types , YULONG empowers global projects to harness high-temperature steam with confidence. Experience the fusion of DIN86030 precision and P22 alloy excellence—where engineering innovation meets industrial durability.

L-aħħar aħbarijiet

-

ANSI 150P SS304 SO FLANGE

AħbarijietFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

AħbarijietJan.20,2025

-

ANSI B16.5 ħanek tal-għonq tal-Weldjar

AħbarijietJan.15,2026

-

ħanek ANSI B16.5 SLIP-ON

AħbarijietApr.19,2024

-

SABS 1123 FLANGE

AħbarijietJan.15,2025

-

DIN86044 ħanek tal-pjanċi

AħbarijietApr.19,2024

-

DIN2527 BLIND FLANGE

AħbarijietApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

AħbarijietApr.23,2024