-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 13, 2024 00:32 Back to list

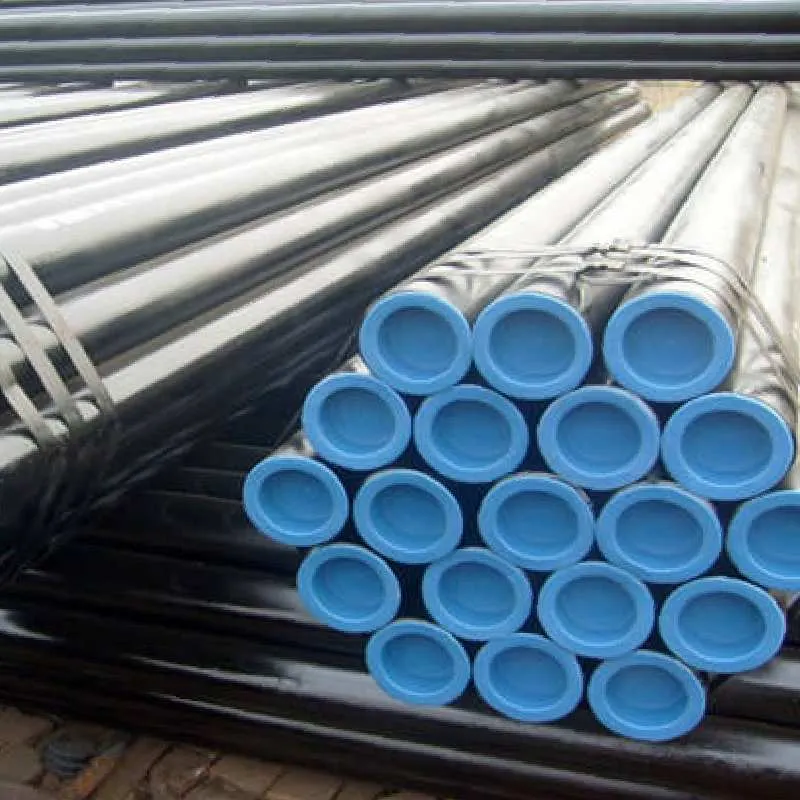

100mm metal pipe

The Significance of 100mm Metal Pipes in Modern Infrastructure

In the realm of modern infrastructure, the utilization of metal pipes—particularly those measuring 100mm in diameter—plays a crucial role across various sectors, including construction, plumbing, and industrial applications. These robust conduits are vital for transportation systems, water supply, and even in the structural framework of buildings. This article delves into the importance of 100mm metal pipes, their applications, material specifications, and the benefits they offer to engineers and builders alike.

Versatility in Applications

100mm metal pipes are immensely versatile, employed in various applications due to their reliability and strength. In plumbing systems, they are often used for carrying water and waste, ensuring smooth flow while minimizing leaks. In industrial settings, these pipes are essential for transporting gases and liquids, effectively supporting the manufacturing process. Furthermore, they are common in HVAC systems where they facilitate heating, ventilation, and air conditioning processes, ensuring that buildings maintain comfortable climates.

Material Specifications

The materials used to manufacture 100mm metal pipes significantly influence their performance and durability

. Common materials include carbon steel, stainless steel, and aluminum. Carbon steel pipes are known for their strength and resistance to impact, making them suitable for high-pressure applications. Stainless steel, on the other hand, offers excellent corrosion resistance, which is essential for piping systems that handle corrosive substances. Meanwhile, aluminum pipes are lightweight and resistant to rust, making them ideal for applications where weight is a critical factor.Additionally, the thickness of the pipe walls can vary based on the pressure they are designed to withstand. Generally, thicker walls are used for high-pressure systems, ensuring safety and longevity. Engineers must carefully select the appropriate material and thickness to suit the specific demands of their projects.

Manufacturing and Quality Standards

100mm metal pipe

The manufacturing process of 100mm metal pipes adheres to strict quality standards to ensure reliability and safety. Various international standards, such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization), provide guidelines for the production of metal pipes. These standards encompass aspects such as material quality, dimensional accuracy, and testing procedures, ensuring that pipes meet safety and performance criteria.

Moreover, advances in manufacturing technology have resulted in enhanced quality control measures. Techniques like non-destructive testing (NDT) help in identifying any potential defects in pipes before they are deployed, reducing the risk of failures and maintenance costs associated with defective materials.

Benefits of Using 100mm Metal Pipes

One of the significant advantages of using 100mm metal pipes is their durability. Unlike plastic alternatives, metal pipes can withstand extreme temperatures and pressures, making them suitable for various environments, from frozen tundras to scorching deserts. Furthermore, metal pipes have a long lifespan, which, coupled with low maintenance requirements, translates into cost savings for construction projects.

Another benefit is the ease of installation and integration into existing systems. Due to their standardized dimensions and compatibility with various fittings, 100mm metal pipes can be easily combined with other materials and systems, offering flexibility in design and implementation.

Additionally, metal pipes are environmentally friendly. They can be recycled at the end of their life cycle, reducing waste and the demand for new raw materials. This aspect aligns with the growing emphasis on sustainability in construction practices.

Conclusion

In conclusion, 100mm metal pipes are indispensable components in the infrastructure of modern society. Their versatility, durability, and adherence to manufacturing standards make them suitable for various applications, from plumbing to industrial processes. By understanding the significance of these pipes, engineers and builders can make informed decisions that enhance the safety, efficiency, and sustainability of their projects. As infrastructure continues to evolve, the role of metal pipes remains foundational, contributing to the resilience and functionality of the systems we rely on daily.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024