-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 05, 2024 13:45 Back to list

Exploring the Benefits of 10% 20-Inch Galvanized Steel Pipe in Construction Applications

The Versatility and Importance of 10% 20 Inch Galvanized Pipe

When it comes to industrial applications and infrastructure, the choice of materials can greatly influence the efficiency, safety, and longevity of various systems. One such essential material is the galvanized pipe, particularly the 10% 20-inch galvanized pipe, which has gained recognition for its strength, durability, and resistance to environmental elements.

What is Galvanized Pipe?

Galvanized pipes are carbon steel pipes that have been coated with zinc to prevent rusting and corrosion, a common issue in metal pipelines exposed to moisture and harsh environments. The galvanization process involves hot-dipping the steel into molten zinc, which forms a protective layer. This technique significantly extends the lifespan of the pipes, making them ideal for various applications, including water supply, sewage, heating systems, and gas lines.

The 10% 20 Inch Dimension

The designation 10% 20 inch refers to the nominal diameter of the pipe, which is 20 inches. This measurement denotes the inside diameter, essential for determining the flow rate of fluids within the pipe. The 10% aspect may refer to the wall thickness percentage or specifications related to the strength of the material, though it may not be a standard terminology. In industrial contexts, a thicker wall is often preferred for added strength, especially in high-pressure applications.

Applications in Various Industries

The 10% 20-inch galvanized pipe's attributes make it a popular choice across several sectors

1. Construction and Infrastructure These pipes are frequently used in the construction of buildings, bridges, and highways due to their robust nature. They can efficiently transport water, gas, or liquid waste, ensuring systems remain intact under various environmental conditions.

2. Agriculture In agricultural settings, the durability of galvanized pipes allows for reliable water management systems. Farmers can use these pipes for irrigation systems, ensuring water delivery without the fear of pipe degradation.

10 inch galvanized pipe

3. Oil and Gas The energy sector relies on galvanized pipes for transporting crude oil and natural gas. Their resistance to corrosion makes them suitable for handling substances that can quickly degrade other materials.

4. Fire Protection Systems With the strict regulations surrounding fire safety, galvanized pipes are often used in fire sprinkler systems due to their ability to withstand heat and pressure, ensuring reliable performance in emergencies.

Advantages of Using 10% 20 Inch Galvanized Pipe

- Corrosion Resistance The primary benefit of galvanized pipes is their protection against rust and corrosion, which significantly reduces maintenance costs over time.

- Strength and Durability These pipes are known for their high tensile strength and ability to endure heavy loads, making them suitable for a variety of industrial applications.

- Cost-Effectiveness While the initial investment may be higher than some alternatives, the longevity and low maintenance of galvanized pipes often lead to lower long-term costs.

- Versatility The adaptability of 10% 20-inch galvanized pipe allows it to be used in different environments, whether underground, above ground, or submerged in water.

Conclusion

The 10% 20-inch galvanized pipe stands as a testament to the evolution of materials used in industrial and construction applications. Its corrosion resistance, strength, and versatility make it an indispensable component across multiple sectors. As industries continue to seek durable and reliable solutions, the importance of galvanized pipes will undoubtedly remain significant. Whether for constructing infrastructure, managing agricultural resources, or ensuring safety through fire protection systems, the role of galvanized pipes will continue to be integral in supporting essential services in our daily lives.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

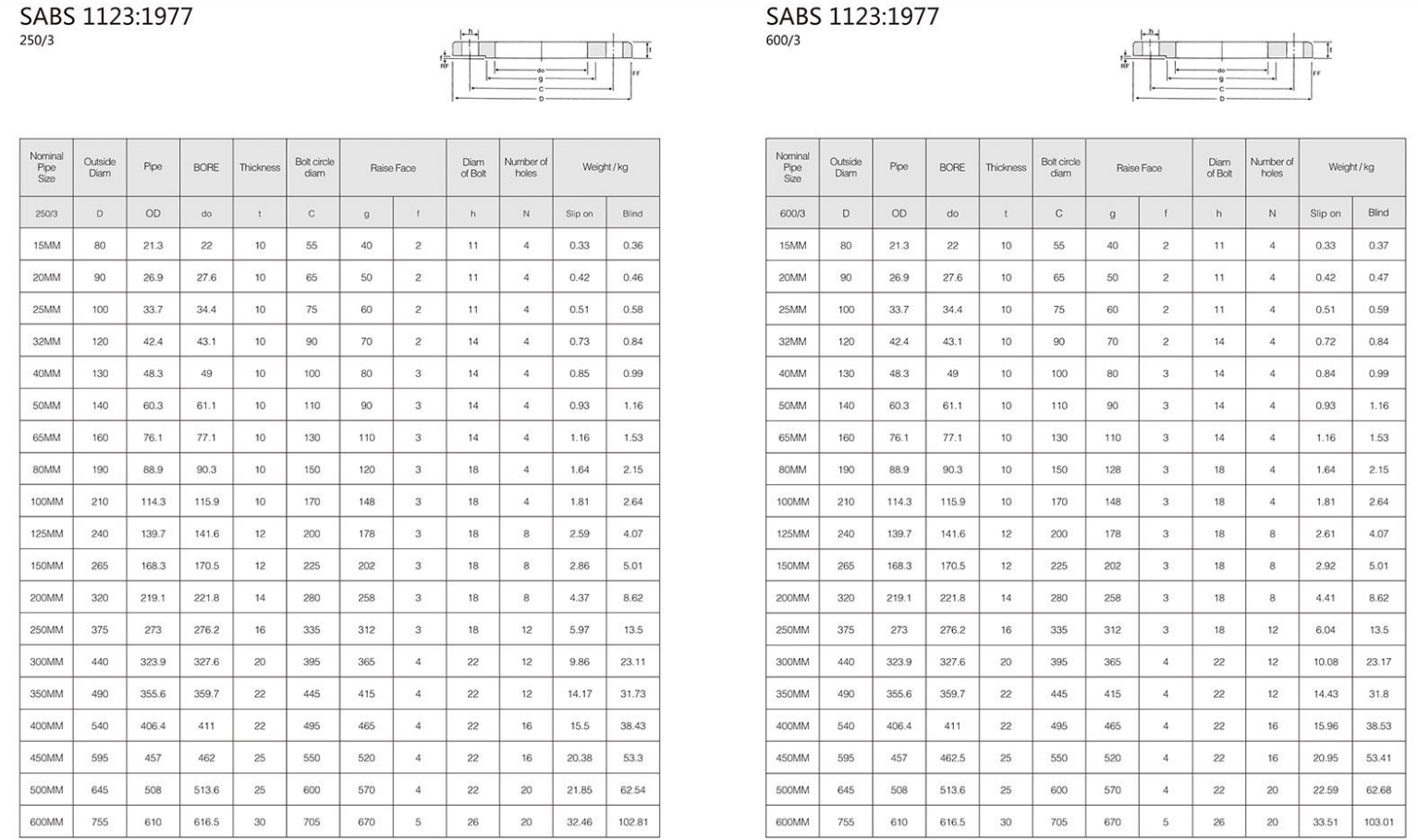

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024