-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 05, 2024 01:08 Back to list

1 1 2 45 degree elbow

Understanding 1% 201% 202% 45 Degree Elbows in Piping Systems

When it comes to piping systems, precision and efficiency in design and installation are vital for optimal performance. One critical component in these systems is the elbow, particularly the 1% 201% 202% 45 degree elbow. This article delves into the significance of this particular fitting, its applications, and why understanding these specifications is paramount in engineering and construction processes.

What is a 45 Degree Elbow?

A 45 degree elbow is a type of pipe fitting used to change the direction of the flow within a piping system. As the name suggests, it changes the angle of the flow by 45 degrees, effectively allowing for a more gradual transition compared to sharper angles, such as 90 degrees. This gradual change is essential in reducing turbulence, ensuring smoother flow, and minimizing pressure drops, which is crucial for maintaining the efficiency of the system.

The 1% 201% 202% Specification

The terms 1% 201% and 202% refer to specific performance criteria and design specifications that engineers must adhere to when selecting elbows for piping systems. These percentages often relate to tolerances and material properties, indicating the allowable deviations in size, shape, or performance characteristics of the elbow fittings.

1. 1% Tolerance This typically refers to the precision with which the elbow must be manufactured. A 1% tolerance means that the dimensions of the elbow can vary by 1% from the specified measurements. This level of precision is often necessary in high-pressure and high-temperature applications.

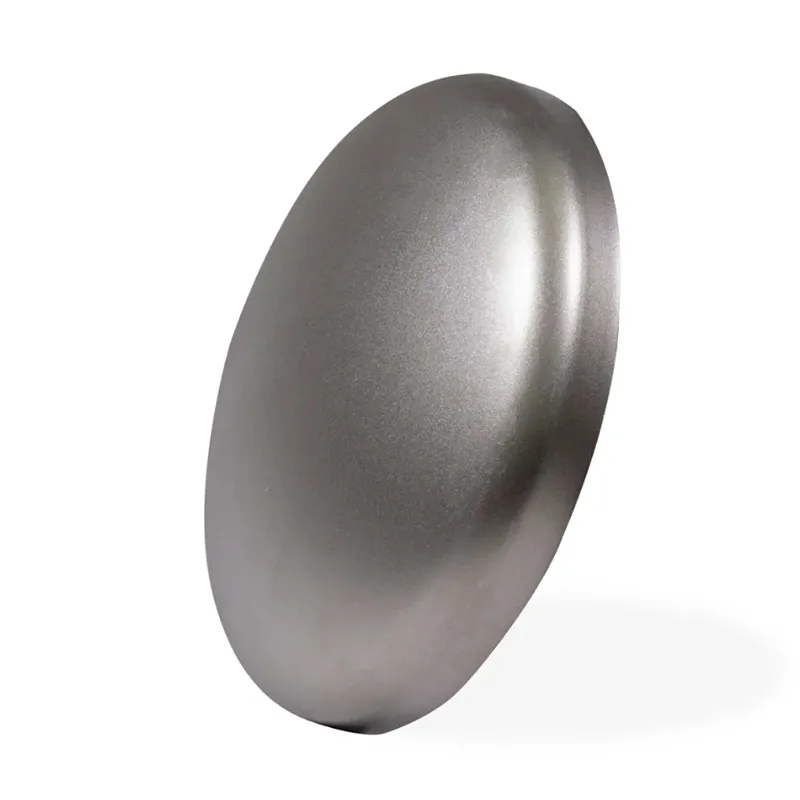

1 1 2 45 degree elbow

2. 201% and 202% Specifications These specifications indicate the specific material grades or performance standards that the elbows must meet. For instance, these might refer to corrosion resistance, strength, flexibility, or fatigue resistance. Understanding and adhering to these specifications can be crucial in environments where chemical exposure or fluctuating temperatures could compromise the integrity of the piping system.

Applications of 45 Degree Elbows

The 45 degree elbow is widely used across various industries, including oil and gas, water treatment, HVAC, and food processing. Its applications are diverse

- Oil and Gas In the oil and gas industry, these elbows are often used to direct the flow of hydrocarbons through pipelines, where maintaining pressure and reducing turbulence is critical. - Water Treatment In water treatment facilities, 45 degree elbows assist in redirecting water flow, ensuring effective filtration and purification. - HVAC Systems In heating, ventilation, and air conditioning systems, they play an essential role in maintaining airflow and minimizing energy loss. - Food Processing In this industry, stainless steel 45 degree elbows are commonly used due to their excellent corrosion resistance and hygiene standards.

Conclusion

In summary, understanding the significance of the 1% 201% 202% 45 degree elbow in piping systems is crucial for engineers and professionals in various industries. These fittings not only facilitate smooth transitions in flow direction but also play a pivotal role in maintaining system efficiency and integrity. By adhering to the specified tolerances and material requirements, engineering teams can ensure that their systems operate safely and effectively, ultimately leading to reduced downtime and enhanced overall performance. Whether in a bustling industrial plant or a residential HVAC installation, the impact of a well-chosen elbow fitting cannot be underestimated.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024