-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 17, 2025 02:32 Back to list

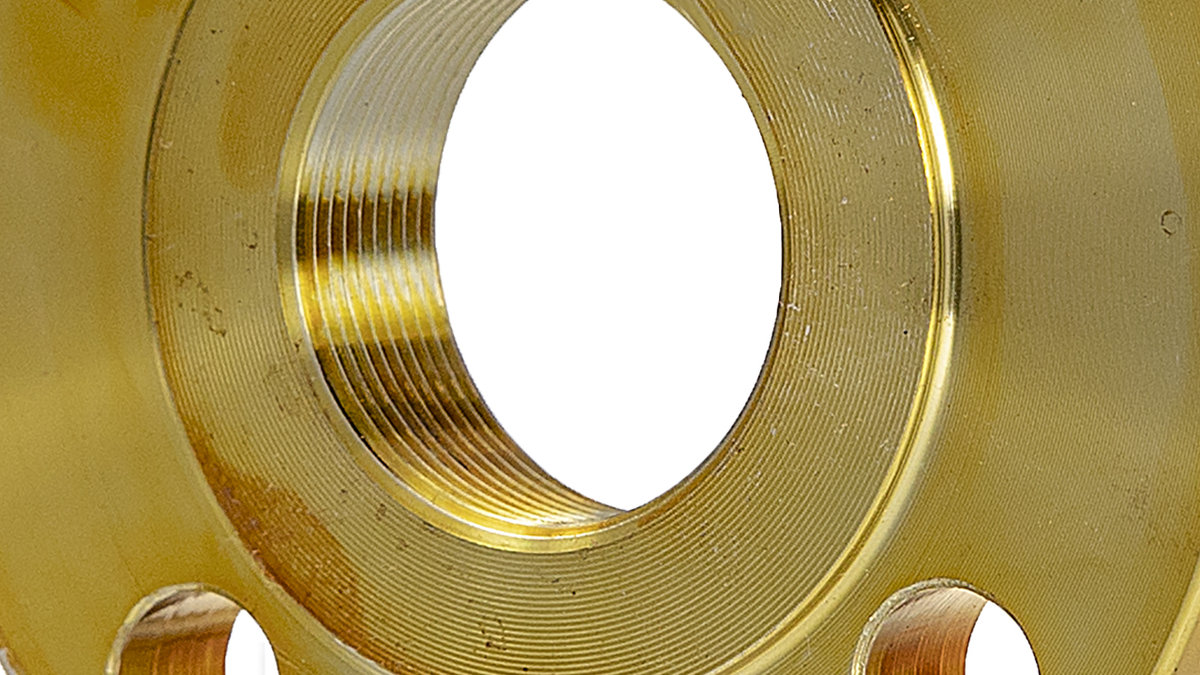

metal threaded pipe fittings

Navigating the world of industrial materials, especially something as specific as a 1 1 2 metal pipe, can be quite complex. Understanding the various aspects and applications of these metal pipes requires not only experience but also expertise, authoritativeness, and trustworthiness. This article delves into the characteristics, uses, and considerations pertaining to 1 1 2 metal pipes, providing a robust resource for industry professionals and consumers alike.

1. Material Selection The choice of material heavily influences performance and longevity. Steel offers robustness, copper provides excellent heat conductivity, and aluminium is lightweight and resistant to corrosion. Understanding the specific requirements of your application is essential in making an informed choice. 2. Environmental Considerations Ensure the selected pipe can handle the environmental conditions. For outdoor or exposed pipelines, consider corrosion resistance and any need for additional coatings or treatments to prolong life and maintain integrity. 3. Compliance and Standards It's critical to ensure the metal pipes meet local building codes and industry standards. Non-compliance can lead to system failures and legal implications, making it essential to source your materials from reputable suppliers who adhere to international quality standards. 4. Installation Expertise Proper installation is as crucial as selecting the right material. Engaging skilled professionals to install these metal pipes ensures that they are correctly fitted and sealed, minimizing future problems such as leaks or bursts under pressure. Trustworthiness in Sourcing and Usage To ensure you're purchasing high-quality 1 1 2 metal pipes, seek suppliers with a track record of reliability and quality assurance. Reviews and testimonials from industrial peers can be invaluable. Transparency regarding material sourcing, production methods, and any testing or certifications can provide peace of mind and ensure that the product will perform as expected. Moreover, regular maintenance checks and timely replacement of worn-out sections can prevent larger issues, ensuring the longevity and reliability of the application. Establishing a routine check can greatly extend the life of these pipes, particularly in high-stress environments where their failure could result in significant downtime and repair costs. In conclusion, navigating the details surrounding 1 1 2 metal pipes requires a blend of technical expertise and practical experience. By focusing on the right material, environmental factors, regulatory compliance, and installation practices, professionals can ensure the effective and reliable use of these pipes in various applications, reinforcing their role as a cornerstone in modern infrastructure and industrial usage.

1. Material Selection The choice of material heavily influences performance and longevity. Steel offers robustness, copper provides excellent heat conductivity, and aluminium is lightweight and resistant to corrosion. Understanding the specific requirements of your application is essential in making an informed choice. 2. Environmental Considerations Ensure the selected pipe can handle the environmental conditions. For outdoor or exposed pipelines, consider corrosion resistance and any need for additional coatings or treatments to prolong life and maintain integrity. 3. Compliance and Standards It's critical to ensure the metal pipes meet local building codes and industry standards. Non-compliance can lead to system failures and legal implications, making it essential to source your materials from reputable suppliers who adhere to international quality standards. 4. Installation Expertise Proper installation is as crucial as selecting the right material. Engaging skilled professionals to install these metal pipes ensures that they are correctly fitted and sealed, minimizing future problems such as leaks or bursts under pressure. Trustworthiness in Sourcing and Usage To ensure you're purchasing high-quality 1 1 2 metal pipes, seek suppliers with a track record of reliability and quality assurance. Reviews and testimonials from industrial peers can be invaluable. Transparency regarding material sourcing, production methods, and any testing or certifications can provide peace of mind and ensure that the product will perform as expected. Moreover, regular maintenance checks and timely replacement of worn-out sections can prevent larger issues, ensuring the longevity and reliability of the application. Establishing a routine check can greatly extend the life of these pipes, particularly in high-stress environments where their failure could result in significant downtime and repair costs. In conclusion, navigating the details surrounding 1 1 2 metal pipes requires a blend of technical expertise and practical experience. By focusing on the right material, environmental factors, regulatory compliance, and installation practices, professionals can ensure the effective and reliable use of these pipes in various applications, reinforcing their role as a cornerstone in modern infrastructure and industrial usage.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024