-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 04, 2024 15:42 Back to list

Galvanized Pipe Specifications for 1% 201% and 8% Applications in Construction

Understanding 1% 201% 8% Galvanized Pipe

When discussing pipes and their various configurations, one type that comes up frequently is galvanized pipe. This particular type of piping plays a crucial role in construction, plumbing, and various industrial applications due to its durability and resistance to corrosion. The term 1% 201% 8% galvanized pipe might sound a bit technical, but once broken down, it reveals significant insights into the material’s composition and its implications for users.

What is Galvanized Pipe?

Galvanized pipe is primarily wrought iron or steel pipe that has been coated with a layer of zinc to protect it from corrosion. The galvanization process involves dipping the pipe in molten zinc, which creates a protective barrier that prevents rust—a common issue for pipes exposed to moisture. This makes galvanized pipes particularly useful in outdoor environments and situations where pipes are in direct contact with water.

Composition Breakdown

The specific percentages mentioned—1%, 201%, and 8%—refer to various alloying elements and potential specifications concerning the material’s makeup. While it’s essential to interpret these figures correctly, they can indicate the type of steel used and the corresponding quality.

1. 1% This percentage can represent the amount of carbon in the alloy. Low carbon content in steel is advantageous because it increases the metal’s malleability and ductility, making it easier to work with during installation and shaping.

2. 201% This might refer to the percentage of chromium in the pipe alloy. Chromium is a crucial element that enhances the corrosion resistance of stainless steel. Commonly, higher chromium content is beneficial in environments prone to oxidation and rust. However, it’s essential to clarify that 201% does not function in conventional terms; this might be a misinterpretation or symbolic representation of high-quality standards in manufacturing galvanized pipes.

3. 8% This percentage might denote nickel content, essential for durability and strengthening the steel. Nickel enhances the corrosion resistance of steel, ensuring longevity and performance even under challenging conditions. In combination with the right carbon and chromium levels, nickel can significantly influence the overall performance and resilience of the piping.

1 1 8 galvanized pipe

Advantages of Using Galvanized Pipe

Galvanized pipes offer multiple advantages that make them a preferred choice for various applications

- Corrosion Resistance The zinc coating forms a barrier that protects the underlying metal from rust, significantly increasing the lifespan of the pipe. - Strength and Durability Piping made from galvanized steel is less likely to bend or break under pressure compared to alternatives like PVC or copper, making it ideal for high-pressure applications.

- Cost-Effectiveness Galvanized pipes are economical. While they can be more expensive than plastic pipes upfront, their longevity and reduced need for replacement make them a cost-effective option over time.

Applications of Galvanized Pipes

Galvanized pipes are widespread across various sectors. They are extensively used in residential plumbing systems, fire sprinkler systems, and agricultural applications. Many industrial applications also rely on galvanized piping for various fluid transport mechanisms due to its strength and resistance to environmental wear.

Conclusion

Understanding the specifications and benefits of galvanized pipes—specifically those outlined by the 1%, 201%, and 8% terminology—can help consumers and professionals make informed choices. By prioritizing corrosion resistance, durability, and overall strength, galvanized pipes remain a steadfast option in plumbing and industrial applications. As technology advances, ongoing discussions about achieving optimal metal composition will continue to enhance the performance of galvanized materials, ensuring their place in the construction landscape for years to come.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

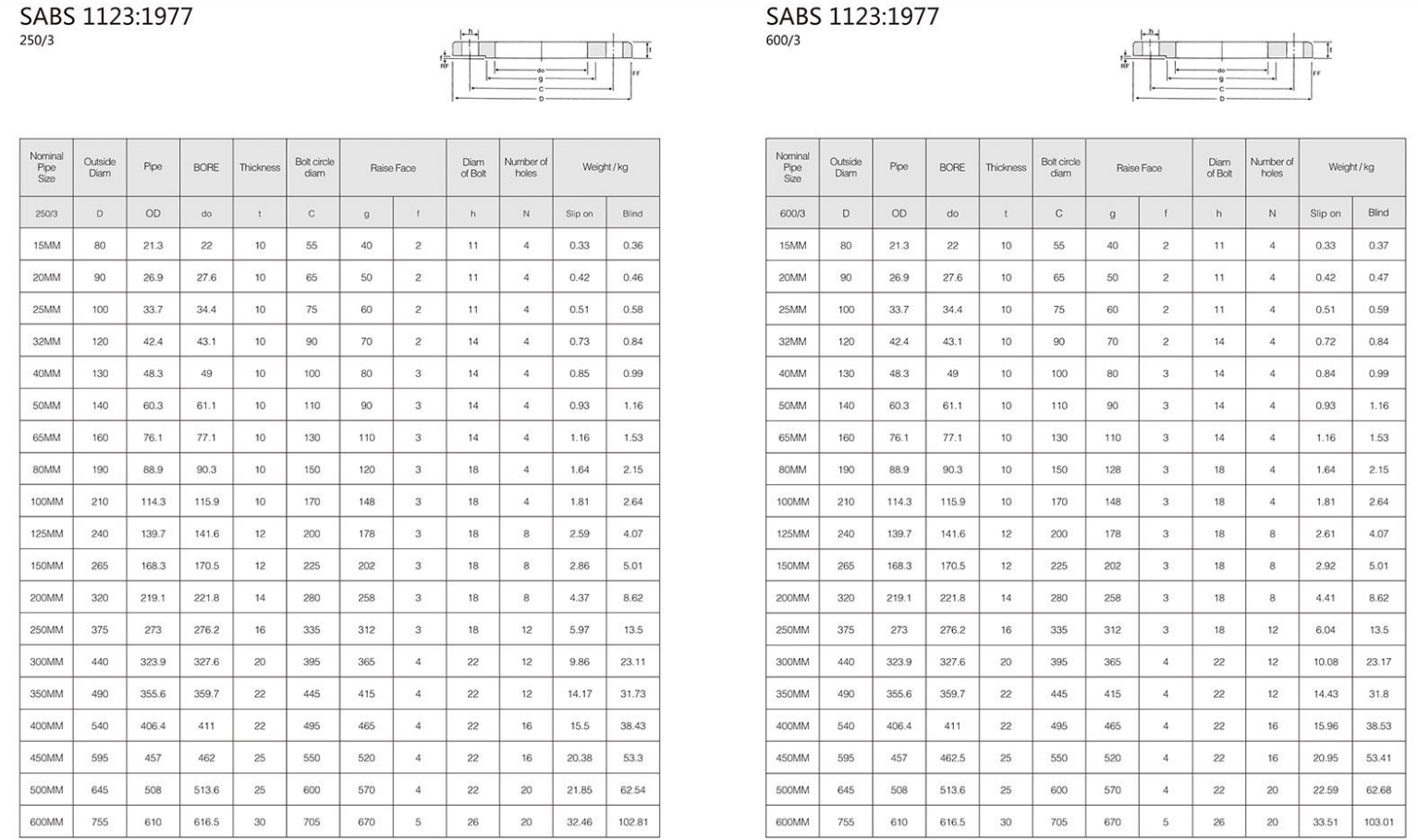

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024