-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 20, 2024 02:08 Back to list

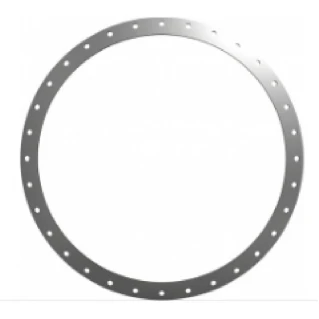

12 150 lb flange

Understanding the 12% 150 lb Flange A Comprehensive Guide

Flanges are essential components in the piping industry, serving as a means to connect two pipes, valves, or other equipment. They play a crucial role in the integrity and safety of piping systems, and understanding their specifications and applications is vital for engineers and technicians. One particular type of flange that often comes up in discussions about pressure and material properties is the 12% 150 lb flange.

Definition and Context

A flange is a mechanical component used to connect sections of pipe, or to connect pipe to a valve or pump. The terminology associated with flanges may seem complex at first glance, but breaking it down can provide clarity. The 150 lb designation refers to the pressure-temperature rating of the flange, indicating that it is designed to withstand certain pressures at specified temperatures. The term 12% generally refers to the specific percentage of material properties, often related to its yield strength, elongation, or a certain characteristic of the flange.

Materials and Strength

Flanges can be made from a variety of materials including stainless steel, carbon steel, and alloyed materials. The choice of material for a 12% 150 lb flange heavily depends on the application and the environment in which it will be used. For instance, stainless steel flanges are often preferred in corrosive environments due to their resistance to rust and oxidation.

The 12% in this context might represent the allowable percentage of deformation or yield strain before permanent deformation occurs, significantly influencing the structural integrity during high-stress situations. This allows for a margin of error and ensures that the flange maintains its shape under varying conditions.

Pressure Ratings

12 150 lb flange

The term 150 lb is a common standard in the American Society of Mechanical Engineers (ASME) B16.5 and B16.47 standards, which categorize the pressure ratings of flanges. A 150 lb flange can generally withstand pressures of up to 285 PSI at a temperature of 100°F, making it suitable for many industrial applications. However, this rating may change with temperature alterations, and it is critical to consult pressure-temperature charts specific to the material used for precise applications.

Applications

12% 150 lb flanges are widely utilized in various industries, including oil and gas, chemical manufacturing, and water supply systems. Their adaptability makes them ideal for high-pressure settings, such as pipelines transporting fluids under substantial pressure. The robustness of the flange allows for reliable sealing, which is paramount for preventing leaks and maintaining system integrity.

In oil and gas applications, for instance, flanges must meet stringent safety regulations and perform under extreme conditions, including high pressure and temperature fluctuations. Similarly, in chemical manufacturing, flanges can be subjected to corrosive substances, thus requiring careful selection of materials and specifications to ensure longevity and safety.

Installation and Maintenance

Proper installation of flanges is crucial for optimal performance. This usually involves ensuring the flange surfaces are clean and free from debris, matching the bolt hole patterns, and applying the correct torque to the bolts during assembly. Regular maintenance checks are also recommended to identify any signs of wear or fatigue before they can lead to failures.

In summary, the 12% 150 lb flange is an integral part of many industrial systems. Its design allows for secure and reliable connections under considerable pressure, making it a staple in piping applications. Understanding its specifications, including materials, pressure ratings, and installation requirements, is essential for ensuring the safety and efficiency of pipeline systems. With proper selection and maintenance, these flanges can provide excellent service and longevity in demanding environments.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024