-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 16, 2024 16:58 Back to list

1 2 45 degree elbow

Understanding the 1% 2% 45 Degree Elbow Applications and Considerations

The 1% 2% 45 degree elbow is a term that resonates in various fields, particularly in engineering, plumbing, and construction. This specific designation often refers to a piping configuration that facilitates the flow of liquids and gases while assisting in directional changes within a piping system. Understanding the properties and applications of this elbow design can significantly impact efficiency, material usage, and overall project success.

The Concept of Elbows in Piping Systems

In piping systems, elbows are crucial components that allow the pipeline to change direction, enabling it to navigate around obstacles or merge with other lines. Elbows are categorized by their degree of curvature, with common angles being 90 degrees, 45 degrees, and sometimes 22.5 degrees. The term “1%” and “2%” may refer to the allowable tolerances in alignment or the gradient of the pipeline, which are critical for ensuring optimal flow and pressure.

Importance of the 45 Degree Angle

The 45 degree elbow is particularly valuable as it strikes a balance between a dramatic turn and gentle flow alteration. When compared to a 90 degree elbow, a 45 degree turn reduces turbulence in the flow, which can lead to better pressure maintenance and less wear and tear on the piping material. This makes the 45 degree elbow a preferred choice in systems where fluid dynamics are critical, such as in water treatment plants, chemical processing, and HVAC systems.

Applications Across Industries

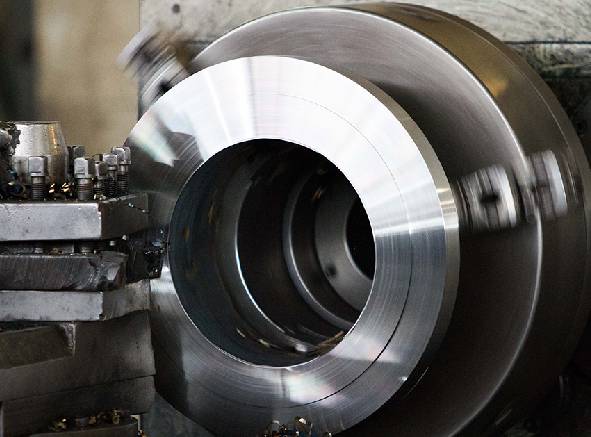

1 2 45 degree elbow

Different industries leverage the benefits of 1% 2% 45 degree elbows. In plumbing, these fittings can improve water flow in residential buildings, minimizing back pressure and preventing potential leaks or pipe bursts. In the oil and gas sector, the ability to maintain pressure and flow efficiency through carefully designed pipeline systems can significantly reduce operational costs and enhance safety. Furthermore, manufacturing plants utilize these elbows in various processes to ensure that materials are moved efficiently through complex systems.

Considerations When Using 1% 2% 45 Degree Elbows

When incorporating these elbows into a system, several factors must be taken into account. Stress analysis and material selection are critical; the elbows must be constructed from materials that can withstand the flow conditions and external influences they will face. Additionally, proper installation practices are necessary to ensure that the system maintains its integrity over time. Any misalignment or improper assembly can create points of weakness, leading to potential failures.

Moreover, the maintenance of these pipes is essential. Over time, sediment buildup may occur at the bends of the elbow, impacting flow rates and system efficiency. Regular inspection and maintenance can prevent these issues, prolonging the life of the piping system.

Conclusion

The 1% 2% 45 degree elbow plays a vital role in modern piping systems across various industries. Its design optimizes fluid dynamics, contributing to efficiency and safety. By understanding its applications, benefits, and the considerations necessary for its effective use, engineers and technicians can enhance piping system performance. Whether in plumbing, manufacturing, or oil and gas, these elbows are indispensable components that facilitate a seamless flow of resources crucial to industrial operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024