-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 13, 2024 02:17 Back to list

12 blind flange

Understanding 12% Blind Flange A Detailed Overview

In the realm of piping and plumbing systems, components like flanges play a crucial role in ensuring the integrity and functionality of various installations. One essential type of flange is the blind flange, specifically those featuring a 12% design. Understanding the characteristics, applications, and advantages of a 12% blind flange can help engineers, fabricators, and technicians make informed decisions for their projects.

What is a Blind Flange?

A blind flange is a solid disk used to seal the end of a pipe or a vessel. Unlike standard flanges that connect to other pipes, a blind flange is used to close off a piping system, allowing for easy access for inspections, maintenance, or modifications without needing to disturb the existing layout. The term blind refers to its lack of any openings, which provides the necessary barrier to maintain pressure within the system.

The 12% Design Feature

The 12% in a 12% blind flange often refers to the flange's thickness, pressure rating, or material specification standard. For instance, it may indicate a specific ratio related to the design pressure or a unique strength feature relevant to the application. Understanding the construction and pressure tolerances of a 12% blind flange is essential for industries like oil and gas, petrochemical, and water treatment, where systems are subjected to high pressures and extreme conditions.

Key Characteristics

1. Material Variety Blind flanges can be constructed from various materials, including carbon steel, stainless steel, and alloys. The choice of material is crucial as it directly affects the flange’s durability, corrosion resistance, and temperature tolerance.

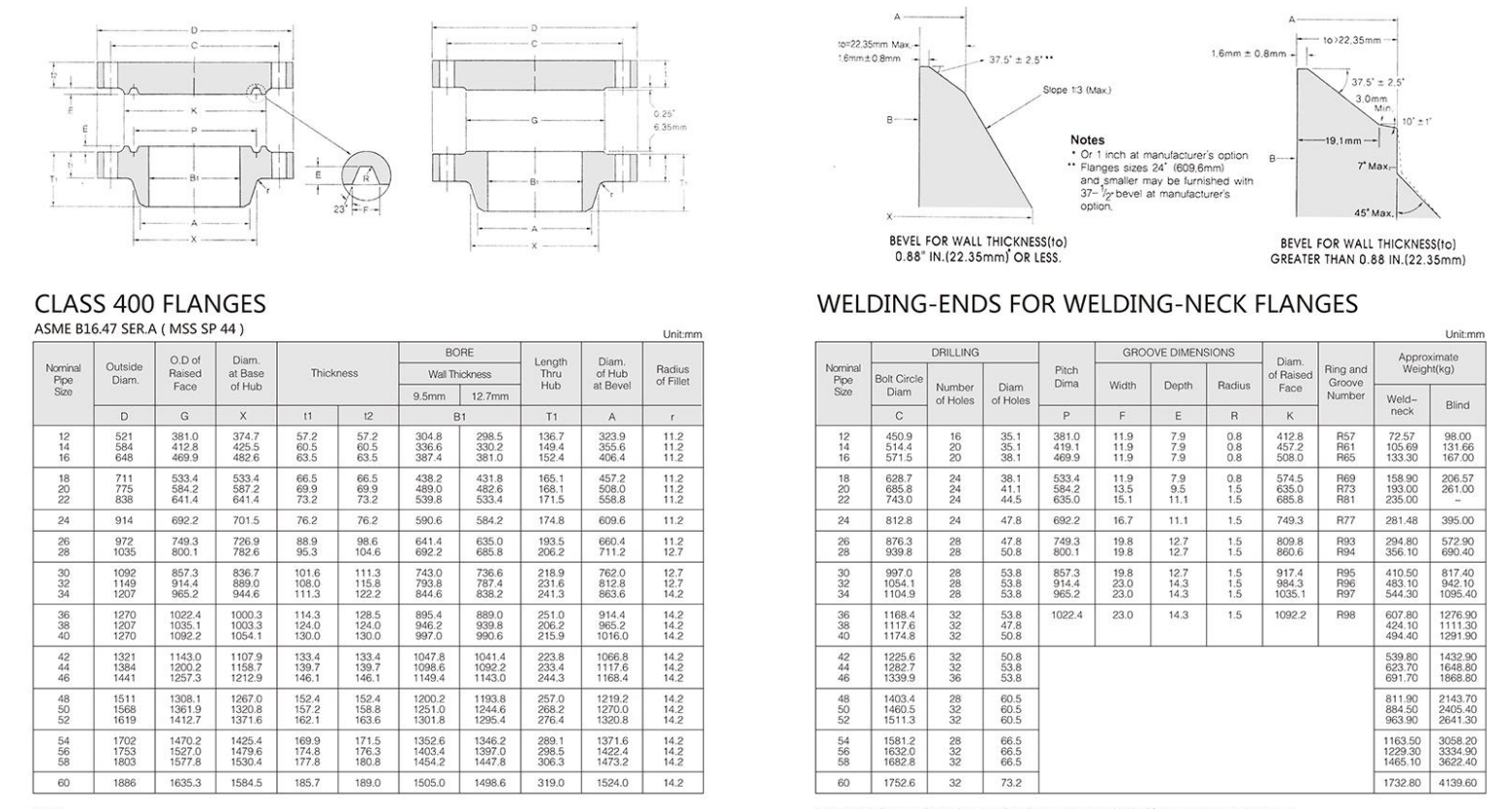

2. Design Standards Blind flanges are manufactured according to various international standards, such as ASME (American Society of Mechanical Engineers) or ASTM (American Society for Testing and Materials). Compliance with these standards ensures that the flange will perform safely and effectively in its intended application.

3. Dimensions and Pressure Ratings The dimensions of a 12% blind flange generally adhere to standard sizes, ensuring compatibility with piping systems. Pressure ratings, often denoted by classes (e.g., Class 150, Class 300), indicate the maximum pressure the flange can handle, which is critical for safeguarding the system against leaks and failures.

12 blind flange

Applications

12% blind flanges find their application in several fields

- Oil and Gas Industry They are used extensively in pipeline systems to seal off unused ends or to segment sections of pipelines for maintenance without interrupting the overall flow system. - Waterworks In municipal water systems, blind flanges help in isolating sections of the pipe for repair or replacement.

- Manufacturing Industrial processes where pressure vessels or reactors are in use also rely on blind flanges to maintain system integrity during maintenance activities.

Advantages of Using 12% Blind Flanges

1. Ease of Maintenance As a non-permanent closure, blind flanges allow for quick access to the system, facilitating routine inspections and repairs without needing extensive alterations to the pipework.

2. Pressure Retention The robust design of a 12% blind flange ensures efficient sealing, greatly minimizing the risk of leaks that could expose systems to pressure loss and potential hazards.

3. Cost-Effectiveness By enabling isolation of specific sections of a piping system, blind flanges can reduce downtime and associated costs during maintenance work.

Conclusion

In summary, the 12% blind flange is a vital component within industrial piping systems, providing necessary sealing and maintenance functionalities. Its ability to withstand pressure and prevent leaks makes it an indispensable part of many industries, enhancing system reliability and operational efficiency. Understanding the specifications and advantages of 12% blind flanges empowers professionals to optimize their piping designs effectively, ensuring safety and performance in their operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024