-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 23, 2024 07:34 Back to list

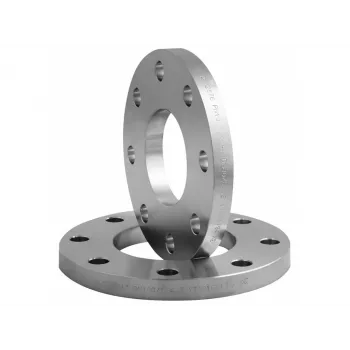

1 2 floor flange

The Importance of 1% 202% Floor Flanges in Modern Construction

In the realm of modern construction and engineering, precision and reliability are paramount. One often overlooked component that plays a critical role in various structural applications is the floor flange, specifically the 1% 202% floor flange. Understanding its significance can aid engineers and builders in making informed decisions that enhance the safety and longevity of their projects.

The Importance of 1% 202% Floor Flanges in Modern Construction

Firstly, the 1% in the designation typically refers to the tolerance level during manufacturing. It indicates that the flange will meet a dimensional accuracy of within 1% of the specified measurements. This high level of precision is crucial, especially in systems that require tight fittings and connections, such as plumbing or HVAC systems. Any deviation could lead to leaks, structural weaknesses, or system failures, which could have dire consequences in commercial and residential settings.

1 2 floor flange

On the other hand, the 202% may refer to the load-bearing capacity of the flange. This percentage signifies that the floor flange can support loads up to 202% of its standard rating under typical conditions. This added robustness is essential for applications involving heavy machinery, industrial equipment, or high foot traffic, where the risk of failure needs to be minimized. By utilizing a floor flange designed to endure substantial loads, engineers can ensure a safer environment for both workers and structures.

In practical applications, 1% 202% floor flanges are commonly utilized in various industries, including manufacturing, automotive, and construction. They are often made from durable materials such as stainless steel or high-grade plastic, which resist corrosion and wear, thereby increasing their longevity and reliability. Selecting the right flange is not just about dimensions; it also involves considering the environmental conditions the flange will be exposed to, such as temperature variations, humidity, and the presence of chemicals.

Innovative engineering designs continue to evolve, integrating advanced manufacturing technologies to enhance the capabilities of floor flanges. Additive manufacturing and precision machining have allowed for the creation of flanges that not only meet stringent standards but also reduce waste and cost-effectiveness in production.

In conclusion, the significance of the 1% 202% floor flange cannot be overstated in essential construction and engineering projects. Its precision and enhanced load-bearing capabilities make it a vital component that contributes to the overall integrity and safety of infrastructures. As the industry progresses, the continuous innovation in flange design and materials will undoubtedly play an essential role in building the structures of tomorrow.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024