-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 15, 2024 09:51 Back to list

12 inch blind flange

The Importance of the 12-Inch Blind Flange in Industrial Applications

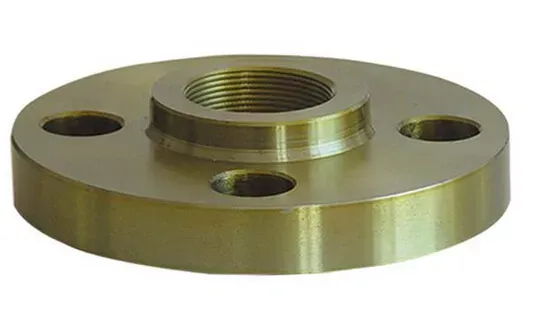

In the world of piping systems and industrial applications, the 12-inch blind flange plays a crucial role. This type of flange is used to close off the ends of pipes or vessels, creating a solid barrier that prevents the flow of fluids or gases. The significance of a blind flange goes beyond its primary function of sealing; its design, material properties, and correct installation are pivotal for the safety and efficiency of a piping system.

What is a Blind Flange?

A blind flange is a flat disk that has bolt holes around its circumference and is used to close a piping system at the end, thereby blocking any fluid or gas from escaping. Unlike other flanges, it does not have a central hole. This makes it an essential component in various applications where a permanent or long-term seal is required. The blind flange is particularly beneficial when access to the interior of the piping system is not frequently needed.

Key Features of a 12-Inch Blind Flange

The 12-inch blind flange is designed to accommodate pipes with a diameter of 12 inches. Its size makes it suitable for various industrial applications, including water treatment plants, chemical processing facilities, and oil refineries. The standard dimensions and bolt hole patterns are defined by various codes and standards, such as ANSI/ASME, which ensures compatibility and interchangeability among other components in the piping system.

Blind flanges come in various materials, including carbon steel, stainless steel, and alloy steel. The choice of material depends on several factors, including the nature of the fluid being transported, temperature, and pressure conditions. For instance, stainless steel blind flanges are commonly used in environments where corrosion resistance is a concern.

Benefits of Using a Blind Flange

1. Security and Safety The primary benefit of a blind flange is its ability to securely seal a pipe. By providing a solid barrier, it reduces the risk of leaks or spills, which can lead to hazardous situations. This is especially critical in industries handling toxic or flammable materials.

12 inch blind flange

2. Ease of Maintenance Blind flanges allow for easy maintenance of piping systems. While they provide a tight seal, they can also be removed when access is necessary. This flexibility is vital during inspections and repairs, ensuring that systems can be maintained without major disruptions.

3. Cost-Effectiveness Although the initial cost of a blind flange may be higher than some other sealing options, its long-term benefits outweigh the expenses. By preventing leaks and maintenance issues, these flanges contribute to the overall efficiency of a piping system.

4. Versatility The design of a blind flange makes it suitable for various applications across different industries. From oil and gas to pharmaceuticals, the 12-inch blind flange can be adapted to meet specific requirements depending on the context of use.

Installation and Recommendations

Proper installation of a blind flange is essential to ensure its effectiveness. The flange must be aligned correctly with the pipe, and the appropriate gasket material should be used to create a seal. Additionally, the bolts that secure the flange should be tightened to the manufacturer’s specifications to prevent any potential leaks.

For optimal performance, it’s advisable to carry out regular inspections of the blind flanges in any industrial setup. Monitoring for signs of wear, corrosion, or other issues can prevent unexpected failures and ensure the continued safety and reliability of the piping system.

Conclusion

In summary, the 12-inch blind flange is a fundamental component in various industries, serving the important function of sealing off piping systems effectively. Its robust design, coupled with the right materials, ensures a secure closure critical for safety and operational efficiency. As industries continue to evolve and standards of safety and performance increase, the significance of the blind flange, particularly the 12-inch version, will remain vital in maintaining the integrity of piping systems. From construction to maintenance, appreciating the role of blind flanges can lead to more efficient and safer industrial operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024