-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 26, 2024 14:53 Back to list

Design Considerations for 150% Flange in Industrial Applications

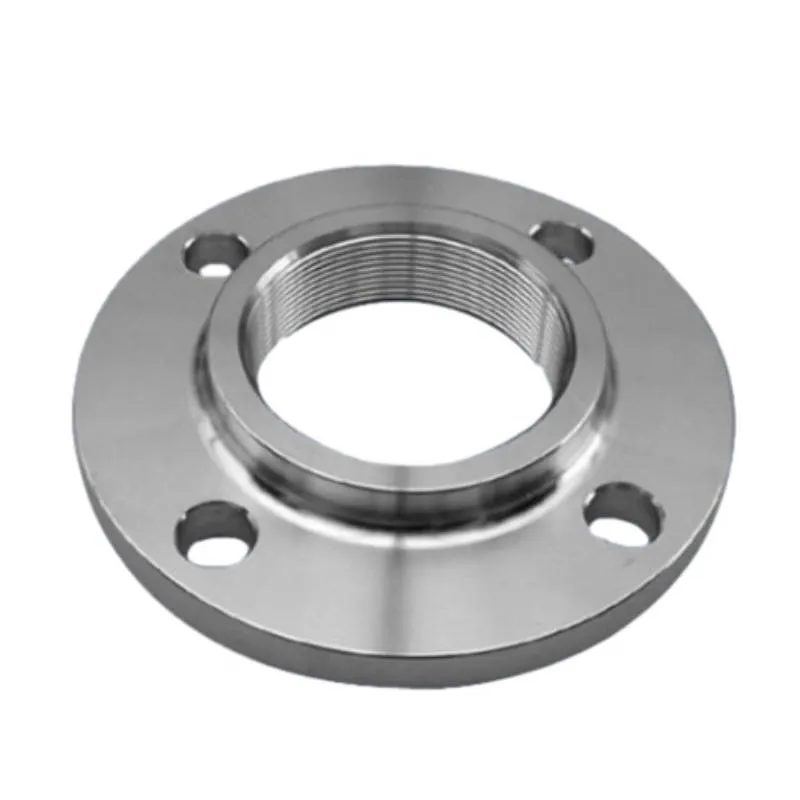

Understanding the 150% Flange Applications and Importance

In the world of engineering and manufacturing, components play critical roles in ensuring machinery and structures function efficiently and safely. Among these components, flanges are essential in various applications, connecting pipes, valves, pumps, and other equipment. A specific category that has garnered attention is the 150% flange—an advanced solution that enhances performance and reliability in industrial settings.

What is a Flange?

Flanges are mechanical components that consist of a disc (the flange itself) with a raised rim. They are designed to be bolted together, allowing for the seamless connection of multiple pipes or equipment. Flanges come in various types and sizes, tailored to meet the specific needs of different applications, including pressure ratings, materials, and designs. They are foundational in ensuring that systems can handle high pressures and temperatures, thereby maintaining the flow of materials safely and effectively.

The Concept of 150% Flange

The term 150% flange refers to a type of flange that is rated for a pressure significantly higher than standard flanges. In this context, the 150% indicates that the flange can handle pressures that are 150% of the designated rating. This feature is especially relevant in high-pressure applications where conventional flanges may fail to provide the necessary strength and integrity.

Applications of 150% Flanges

1. Oil and Gas Industry One of the primary applications of 150% flanges is in the oil and gas sector. Equipment used in drilling and extraction often operates under extreme pressures. The increased reliability offered by these flanges can prevent leaks and catastrophic failures, ensuring safe operations in potentially hazardous environments.

2. Chemical Processing In chemical plants, where reactions can produce volatile substances, the integrity of piping systems is crucial. The use of 150% flanges contributes to greater safety by providing robust connections that withstand the corrosive forces and high pressures encountered during processing.

150 flange

3. Water Treatment Facilities Flanges in water treatment plants must contend with varying pressures due to fluctuations in flow rates and demand. The adaptability of 150% flanges ensures that system integrity is maintained, minimizing the risk of leaks that can lead to contamination.

4. Power Generation In power plants, particularly those that handle steam or gases under high pressure, the need for reliable and robust connections is paramount. 150% flanges are utilized to enhance the safety and performance of piping systems, contributing to the overall efficiency of power generation processes.

Importance of Material Quality

The effectiveness of a 150% flange is heavily dependent on the material from which it is constructed. Common materials include carbon steel, stainless steel, and other alloys that provide the necessary strength and corrosion resistance. Selecting the appropriate material for the specific application is crucial for maximizing performance and durability.

Maintenance and Inspection

Like all mechanical components, 150% flanges require regular maintenance and inspection. This is vital to identify any signs of wear, corrosion, or damage early on. Adhering to maintenance schedules can significantly extend the lifespan of the flanges and the overall system, preventing costly downtimes and repairs.

Conclusion

The 150% flange is an essential innovation in the engineering sector, providing enhanced safety and reliability in high-pressure applications. Its use across various industries, including oil and gas, chemical processing, water treatment, and power generation underscores its importance. By investing in quality materials and adhering to proper maintenance protocols, industries can ensure that these critical components perform optimally, ultimately contributing to safer and more efficient operations. As technology advances, the evolution of flanges and their applications will undoubtedly continue to play a vital role in industrial processes worldwide.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024