-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 09, 2024 09:06 Back to list

150 threaded fittings

Understanding 150% Threaded Fittings Applications and Benefits

In the realm of plumbing and piping systems, threaded fittings are crucial components that ensure a secure and leak-proof connection between pipes. Among various types of fittings, the term 150% threaded fittings refers to a line of products designed for specific pressure ratings and applications. This article will delve into the characteristics, applications, and benefits of 150% threaded fittings, providing insights into why they are preferred in various industries.

What Are 150% Threaded Fittings?

Threaded fittings are mechanical devices that allow the joining of two or more piping components. The 150% designation typically indicates that these fittings are designed to handle pressures significantly above the nominal rating of standard fittings, often reaching up to 150% of their specified pressure rating. This feature makes them suitable for high-pressure applications where safety and reliability are paramount.

These fittings are usually made from durable materials such as stainless steel, carbon steel, brass, or PVC, depending on the intended application. The threading on these fittings ensures a tight and secure fit, preventing leaks and ensuring a long-lasting connection.

Key Applications

150% threaded fittings are widely used in various industries due to their high-pressure capabilities and robust construction. Here are some common applications

1. Oil and Gas Industry The oil and gas sector often operates under high-pressure conditions. The need for secure and leak-proof connections is critical to prevent accidents and ensure operational efficiency. 150% threaded fittings provide a reliable solution for these demanding applications.

2. Chemical Processing Chemical plants require piping systems that can withstand corrosive substances and high pressure. The materials used in 150% threaded fittings, often resistant to many chemicals, make them ideal for connecting pipes in these environments.

3. Water and Wastewater Treatment In water treatment facilities, maintaining the integrity of the piping system is vital. 150% threaded fittings help withstand the pressure from pumps and other equipment, ensuring a stable flow of water through the treatment process.

4. HVAC Systems High-efficiency heating, ventilation, and air conditioning (HVAC) systems require fittings that can handle varying pressures and temperatures. 150% threaded fittings are often employed to connect pipes carrying refrigerants or hot water.

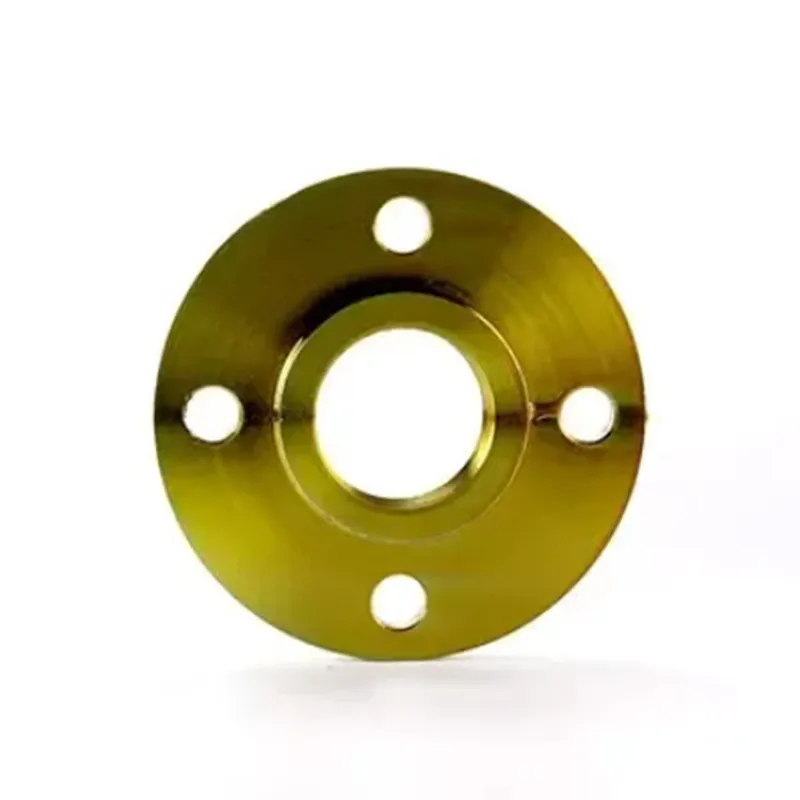

150 threaded fittings

5. Fire Protection Systems Fire sprinkler systems need to maintain high pressures to ensure effective water distribution during emergencies. The reliability of 150% threaded fittings makes them suitable for connecting pipes in these critical systems.

Benefits of 150% Threaded Fittings

There are several advantages to using 150% threaded fittings in various applications

1. Enhanced Safety The ability to withstand higher pressure significantly reduces the risk of leaks and failures, enhancing safety in industrial processes.

2. Longevity Made from robust materials, these fittings often have a longer service life, reducing the need for frequent replacements and maintenance.

3. Versatile Applications Their ability to handle various chemicals and high-pressure conditions makes them versatile and applicable in different industries.

4. Ease of Installation Threaded fittings are relatively easy to install and require minimal tools, speeding up the process of setting up piping systems.

5. Cost-Effective Though they may have a higher upfront cost compared to standard fittings, their durability and reliability can lead to lower long-term maintenance costs.

Conclusion

150% threaded fittings play a pivotal role in ensuring the integrity and efficiency of piping systems across various industries. Their ability to handle high pressure, coupled with their versatility and durability, makes them a preferred choice for applications in oil and gas, chemical processing, and more. As industries continue to evolve and demand safer and more efficient solutions, the importance of high-quality fittings, such as 150% threaded fittings, will only grow. Understanding their features and applications can help stakeholders make informed decisions that enhance operational efficiency and safety in their respective sectors.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024