-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 07, 2024 05:53 Back to list

Understanding 1% ANSI Flange Specifications for Optimal Pipeline Performance

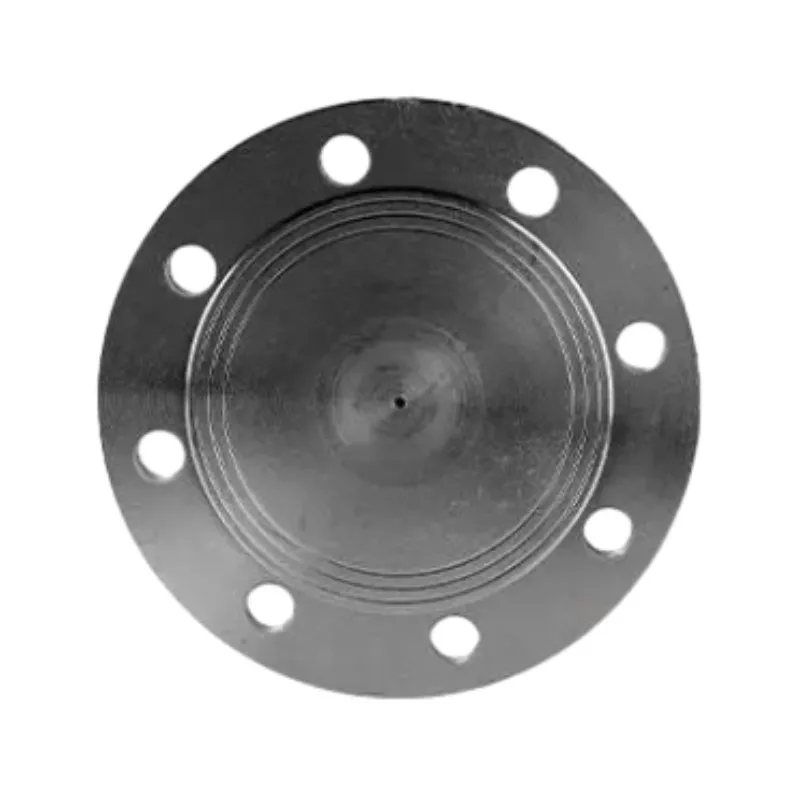

Understanding 1% ANSI Flanges A Comprehensive Overview

Flanges are an essential component in the construction and assembly of piping systems across various industries, including oil and gas, water treatment, and manufacturing. Among the various standards and specifications that govern flanges, ANSI (American National Standards Institute) flanges are widely recognized and utilized. This article delves into the significance, design, applications, and advantages of 1% ANSI flanges.

What is ANSI Flange?

ANSI flanges conform to the standards set by the American National Standards Institute, primarily the ANSI/ASME B16.5 standard. This standard outlines the dimensions, tolerances, and materials for pipe flanges used in pressure applications. ANSI flanges are categorized by different classes that indicate their pressure rating, with common classes ranging from 150 to 2500. The term 1% ANSI flange typically refers to a specific tolerance or characteristic within the ANSI standard.

Characteristics of 1% ANSI Flanges

1% ANSI flanges denote flanges that adhere to specific dimensional tolerances and pressure ratings at a strength level that can withstand stringent operational conditions. The '1%' designation can refer to variations in the manufacturing process, ensuring that the flanges maintain their integrity and performance under pressure. This precision is crucial in applications where even slight deviations can lead to catastrophic results.

Flanges manufactured to 1% ANSI specifications often feature materials such as carbon steel, stainless steel, and alloy steel, providing a blend of strength, corrosion resistance, and longevity. The design of these flanges often includes a flat face, raised face, or ring-type joint, which helps in creating a leak-proof seal when connected to pipes or other flanges.

Applications of 1% ANSI Flanges

1% ANSI flanges are designed for a myriad of applications across various sectors. Some of the most notable include

1. Oil and Gas Industry In upstream, midstream, and downstream processes, flanges play a critical role in connecting pipes, valves, and other equipment. ANSI flanges ensure that the systems can handle the high pressures and aggressive fluids encountered in this industry.

2. Water Treatment Facilities Flanges are used to assemble pipelines and pumps that transport water and wastewater. The durability of ANSI flanges ensures that they can withstand the continuous flow and maintain a secure connection over time.

1 ansi flange

3. Power Plants Flanges are integral in power generation systems, ensuring the safe and efficient transfer of steam, water, and other fluids under high pressures. The reliability of 1% ANSI flanges directly impacts the operational efficiency of these facilities.

4. Chemical Processing In environments where chemicals are transported under pressure, using ANSI flanges minimizes the risk of leaks and spills. The compatibility of materials with various chemicals is critical, and ANSI standards provide guidelines to ensure safety.

Advantages of 1% ANSI Flanges

The use of 1% ANSI flanges offers several advantages

- Safety and Reliability With verified pressure ratings and dimensional tolerances, 1% ANSI flanges contribute to safer and more reliable piping systems. This minimizes the risk of failure due to leaks or ruptures.

- Versatility ANSI flanges can be applied across a variety of industries, making them suitable for multiple applications within diverse environments.

- Standardization The adherence to ANSI standards ensures consistency in manufacturing, which simplifies procurement and maintenance processes for organizations that rely on these components.

- Cost-Effective While the initial investment may be higher due to the precision involved in manufacture, the long-term benefits such as reduced maintenance costs and extended service life make 1% ANSI flanges a cost-effective choice.

Conclusion

1% ANSI flanges are indispensable components in modern piping systems, bringing together safety, efficiency, and versatility. Their adherence to strict ANSI standards ensures that they maintain integrity under pressure, making them crucial for industries that demand the highest reliability. As industries continue to evolve and innovate, the role of ANSI flanges, including those designated under the 1% category, will remain pivotal in achieving operational excellence. Understanding their design and application will help engineers, manufacturers, and operators alike in selecting the right components for their projects.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024