-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 15, 2024 08:34 Back to list

2.5 Mandrel Bends - Precision Bending Solutions for Every Application

Understanding 2.5% Mandrel Bends A Comprehensive Overview

In the realm of piping and tubing fabrication, bends play a crucial role in ensuring that systems function efficiently and effectively. Among the various types of bends, the 2.5% mandrel bend is a particularly noteworthy option, widely utilized in numerous industries, including automotive, aerospace, and manufacturing. This article delves into the characteristics, advantages, and applications of 2.5% mandrel bends, highlighting their significance in modern engineering.

Understanding 2

.5% Mandrel Bends A Comprehensive OverviewOne of the primary advantages of 2.5% mandrel bends is their ability to preserve the cross-sectional area of the pipe. Unlike other methods that can cause deformation, mandrel bends maintain a consistent diameter, allowing for optimal fluid dynamics. This characteristic is particularly important in high-performance applications, such as exhaust systems in automobiles, where maintaining airflow efficiency is paramount.

2.5 mandrel bends

Additionally, 2.5% mandrel bends are favored for their aesthetic appeal. In various industries, especially in automotive design, the smooth and elegant curves of mandrel bends can enhance the overall look of a system, seamlessly integrating functionality with form. This balance of beauty and practicality makes them a preferred choice among engineers and designers alike.

Moreover, the flexibility of mandrel bends allows for intricate designs, accommodating complex routing requirements without compromising system performance. This adaptability is essential in constrained environments where space is limited, such as in custom-built vehicles or aircraft.

In conclusion, 2.5% mandrel bends stand out as a vital component in piping and tubing applications, offering a harmonious blend of performance, aesthetics, and versatility. Their capacity to maintain structural integrity, promote efficient fluid flow, and adapt to various design parameters solidifies their importance across multiple industries. As technology continues to evolve, the applications and manufacturing techniques for mandrel bends are likely to advance, ensuring they remain a staple in engineering practices for years to come.

Latest news

-

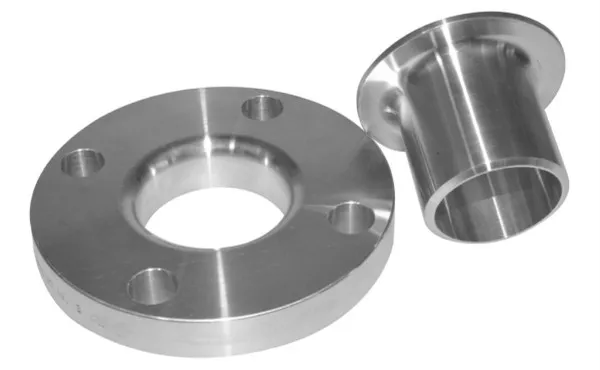

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024