-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 10, 2024 19:49 Back to list

Exploring the Benefits and Applications of 24% Blind Flanges in Engineering Projects

Understanding 24% Blind Flanges Application and Importance in Piping Systems

In the realm of piping systems, flanges play a crucial role in ensuring the integrity and functionality of connections between pipes, valves, pumps, and other equipment. Among the various types of flanges used in industrial applications, the blind flange is particularly notable. This article delves into the specifics of 24% blind flanges, exploring their design, application, and significance within piping systems.

What is a Blind Flange?

A blind flange is a type of flange that is used to seal the end of a piping system. Unlike standard flanges, which are designed to connect to other components, blind flanges do not have a central hole. Their primary purpose is to provide a tight seal at the end of a pipe, preventing the leakage of fluids and gases. This makes them invaluable in various industries, including oil and gas, water treatment, and chemical processing.

The Significance of 24% Blind Flanges

The term 24% blind flange typically refers to a specific design or specification of blind flange that is used in certain applications where the pressure and temperature conditions demand enhanced durability. A blind flange designed with a 24% thickness often implies that it has been optimized for higher pressure applications, accommodating a range of operational challenges.

The significance of using a 24% thick blind flange lies in its ability to withstand substantial pressure without compromising safety. In high-pressure systems, a robust flange is essential to prevent catastrophic failures that can lead to leaks, explosions, and operational downtime. The added thickness not only enhances the structural integrity of the flange but also allows for the successful containment of aggressive fluids or gases that may be transported through the piping system.

Application Areas

Blind flanges, including the 24% variation, are commonly employed in different sectors

24 blind flange

1. Oil and Gas Industry Here, blind flanges play a key role in securing pipeline systems that transport crude oil, natural gas, and various petrochemicals. The reliability of these connections is vital to ensure operational safety and prevent leaks.

2. Chemical Processing In the chemical industry, blind flanges are used to isolate sections of piping or equipment for maintenance or cleaning. The 24% thickness offers additional assurance against the high pressures often encountered in chemical reactions.

3. Water and Wastewater Systems Blind flanges are used to seal off unused sections of pipelines, allowing for easy maintenance and inspection without draining the entire system.

4. Power Generation These flanges are also present in power plants, particularly in steam and gas piping systems where high temperatures and pressures pose a constant challenge.

Design and Standards

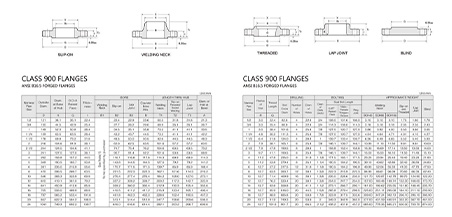

Blind flanges are manufactured to meet various standards, including ANSI, ASME, and API specifications. The design considerations often include material selection, surface finishing, and pressure-temperature ratings. For a 24% blind flange, materials such as carbon steel, stainless steel, and other alloys might be used, depending on the specific requirements of the application.

The correct specification and installation of a blind flange are crucial for system integrity. Factors like bolt spacing, torque specifications, and gasket compatibility must be adhered to in order to ensure optimal performance.

Conclusion

In summary, 24% blind flanges are an essential component in many piping systems across different industries. Their ability to withstand high pressures makes them a preferred choice in demanding applications, ensuring safety and reliability. As industries continue to evolve and face new challenges, the role of robust components such as blind flanges will increasingly become pivotal in maintaining efficient and safe operations. Understanding the importance of these flanges is crucial for engineers, designers, and operators who seek to optimize the performance of piping systems while minimizing risks.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024