-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 17, 2024 18:28 Back to list

24 inch blind flange

Understanding 24-Inch Blind Flanges A Comprehensive Overview

In various industrial applications, flanges play a crucial role in joining pipes, valves, and other equipment. Among the different types of flanges, the blind flange stands out due to its unique functionality and advantages. A blind flange is a flat circular plate used to close off the end of a pipeline or vessel. Specifically, a 24-inch blind flange is designed to fit pipes with a nominal diameter of 24 inches, providing a secure seal and preventing any flow through the pipe.

Types of Blind Flanges

Blind flanges are available in various materials, including steel, stainless steel, and plastic, each suited to different environmental conditions and requirements. For example, stainless steel blind flanges are commonly used in corrosive environments, such as in chemical processing, because of their resistance to rust and corrosion. On the other hand, carbon steel flanges are often employed in high-pressure applications due to their strength and durability.

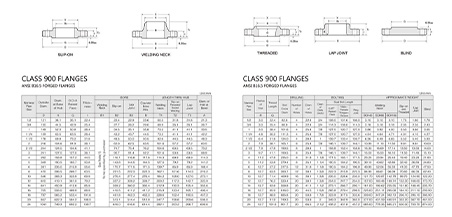

Within the realm of blind flanges, there are several standards and specifications that dictate their design and manufacturing process. Common standards include ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers) ratings, which provide guidelines on dimensions and pressure ratings. For instance, a 24-inch blind flange might be classified under different pressure ratings such as 150, 300, or even 600 pounds per square inch (psi), indicating the maximum pressure it can withstand.

Applications of 24-Inch Blind Flanges

The use of a 24-inch blind flange can be seen across various industries such as oil and gas, water treatment, power generation, and manufacturing. In these sectors, blind flanges are essential for maintenance operations, allowing for the isolation of sections of piping without the need to dismantle the system. This ensures that processes can continue in other areas while repairs are made, leading to increased efficiency and reduced downtime.

Moreover, blind flanges are instrumental in pressure testing systems. By sealing off a pipeline, technicians can safely assess the integrity of the system under pressure, ensuring that there are no leaks or weaknesses that could lead to failures in the future. Once testing is completed, the blind flange can be removed, and the system can be reconnected seamlessly.

24 inch blind flange

Benefits of Using a Blind Flange

One of the primary benefits of utilizing a 24-inch blind flange is its robustness. The design allows it to withstand significant mechanical stress and high-pressure conditions, making it ideal for demanding applications. Furthermore, the installation of a blind flange requires minimal space, simplifying the overall system design compared to other closing methods such as welds or threaded ends.

Another advantage is versatility. Blind flanges can be employed in many configurations, whether in horizontal or vertical installations, providing great flexibility for engineers and designers. Their straightforward installation process allows for quick modifications to be made, which is vital in industries where specifications can change rapidly.

Considerations When Selecting a Blind Flange

When selecting a 24-inch blind flange, several factors should be taken into consideration. The intended application is paramount; understanding the operating environment, the fluid being transported, pressure requirements, and temperature extremes is crucial in making an informed decision. Additionally, compatibility with existing materials must be assessed to avoid galvanic corrosion, which can occur when two dissimilar metals are in contact.

The proper dimensions must be confirmed, including the flange's thickness, bolt hole configuration, and overall diameter. It's advisable to consult relevant industry standards to ensure compliance with all necessary regulations and safety protocols.

Conclusion

In conclusion, a 24-inch blind flange is an essential component in many industrial systems, providing a reliable method for closing off pipelines and facilitating maintenance and testing procedures. With a variety of materials and standards available, the right blind flange can significantly enhance operational efficiency while ensuring system integrity. As industries evolve and technologies advance, the role of blind flanges will continue to be pivotal in ensuring safe and efficient operations across numerous applications.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024