-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 31, 2024 05:04 Back to list

2g pipe weld

Understanding 2G Pipe Weld A Key Technique in Welding

Welding is an essential process in various industries, ranging from construction to manufacturing. Among the numerous welding positions and techniques, the 2G pipe weld position stands out as a vital skill for welders. This article delves into the characteristics, processes, and significance of the 2G pipe weld.

Understanding 2G Pipe Weld A Key Technique in Welding

The 2G position is commonly used in the fabrication and installation of pipelines, particularly in industries like oil and gas, water supply, and sewage. The horizontal orientation of the pipe allows for easier access and visibility, which is beneficial for welders who must inspect their work closely. Additionally, this position facilitates automated welding processes, enabling higher production rates.

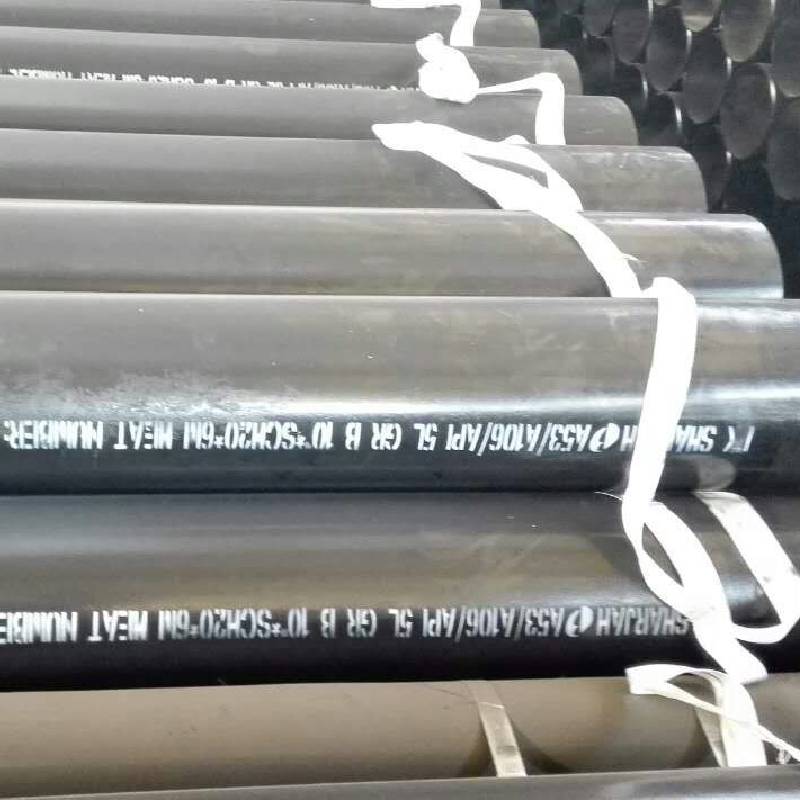

2g pipe weld

Welders typically use various techniques to perform a 2G pipe weld, including TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and stick welding. The choice of technique often depends on the material being welded, the thickness of the pipe, and specific project requirements. For instance, TIG welding is known for its precision and is often used for high-quality welds in stainless steel and aluminum pipes. On the other hand, stick welding may be favored for its versatility and effectiveness in outdoor applications.

Proper preparation and technique are crucial for a successful 2G pipe weld. This includes cleaning the surfaces to be welded, selecting the right filler material, and implementing proper heat settings. Welders must also understand the importance of travel speed, angle, and the arc length, as these factors significantly influence the integrity of the weld.

In conclusion, mastering the 2G pipe weld position is a fundamental aspect of a welder’s skill set. Understanding the nuances of this technique not only enhances a welder’s capabilities but also contributes to the overall safety and reliability of the structures being developed. As industries continue to evolve, the importance of proficient welding techniques like the 2G position remains paramount in ensuring that essential infrastructures are built to last.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024