-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 25, 2024 02:48 Back to list

2-Inch Mandrel Bends for Optimal Exhaust System Performance and Custom Fabrication Solutions

Understanding 2-Inch Mandrel Bends A Comprehensive Guide

Mandrel bends are crucial in various industries, particularly in automotive and piping applications, where smooth curves are necessary to maintain flow and reduce turbulence. Among the different sizes of mandrel bends available, the 2-inch mandrel bend stands out due to its versatility and effectiveness.

What is a Mandrel Bend?

A mandrel bend is a type of bend used to create curves in tubing or piping without causing any deformation or crimping. The bend is made using a mandrel—an internal support structure—designed to maintain the tubing's shape during the bending process. This technique is particularly important in applications where smooth transitions are necessary, such as exhaust systems, turbo piping, and fluid transport.

Advantages of 2-Inch Mandrel Bends

1. Flow Efficiency The primary advantage of using a 2-inch mandrel bend is the smooth transition it provides. Unlike traditional bends, which may create sharp angles and disrupt fluid flow, mandrel bends offer a gentle arc that enhances efficiency. This is particularly beneficial for exhaust systems in automotive applications, where restricting flow can lead to power loss.

2. Durability Mandrel bends typically exhibit higher durability compared to their non-mandrel counterparts. The process of bending with a mandrel minimizes the risk of metallurgical damage, ensuring that the integrity of the tubing is maintained. This durability is crucial for applications exposed to high temperatures and pressures.

2 inch mandrel bends

3. Customizable Shapes Mandrel bends can be manufactured in various angles and radii, allowing for custom solutions tailored to specific needs. Whether you require a tight 90-degree bend or a gradual curve, 2-inch mandrel bends can be produced to meet precise specifications.

4. Improved Aesthetics In addition to their functional advantages, mandrel bends also enhance the visual appeal of any installation. The smooth, rounded appearance of these bends contributes to a cleaner and more professional look, which is particularly valuable in show cars and custom builds.

Applications of 2-Inch Mandrel Bends

The applications of 2-inch mandrel bends are extensive. In automotive settings, they are commonly used in exhaust systems, intake piping, and intercooler setups. Their ability to maintain airflow while withstanding high temperatures makes them ideal for performance vehicles.

Beyond automotive use, 2-inch mandrel bends play a significant role in various industrial settings. They are utilized in HVAC systems, chemical processing, and plumbing applications, where a reliable, efficient flow of gases or liquids is necessary.

Conclusion

In conclusion, 2-inch mandrel bends are an essential component in many industries, offering a unique combination of efficiency, durability, and aesthetic appeal. Their ability to maintain smooth fluid flow while withstanding the rigors of high-pressure applications makes them a preferred choice for engineers and DIY enthusiasts alike. Whether in automotive projects or industrial applications, understanding the benefits of mandrel bends can significantly contribute to the success of any venture involving tubing or piping.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

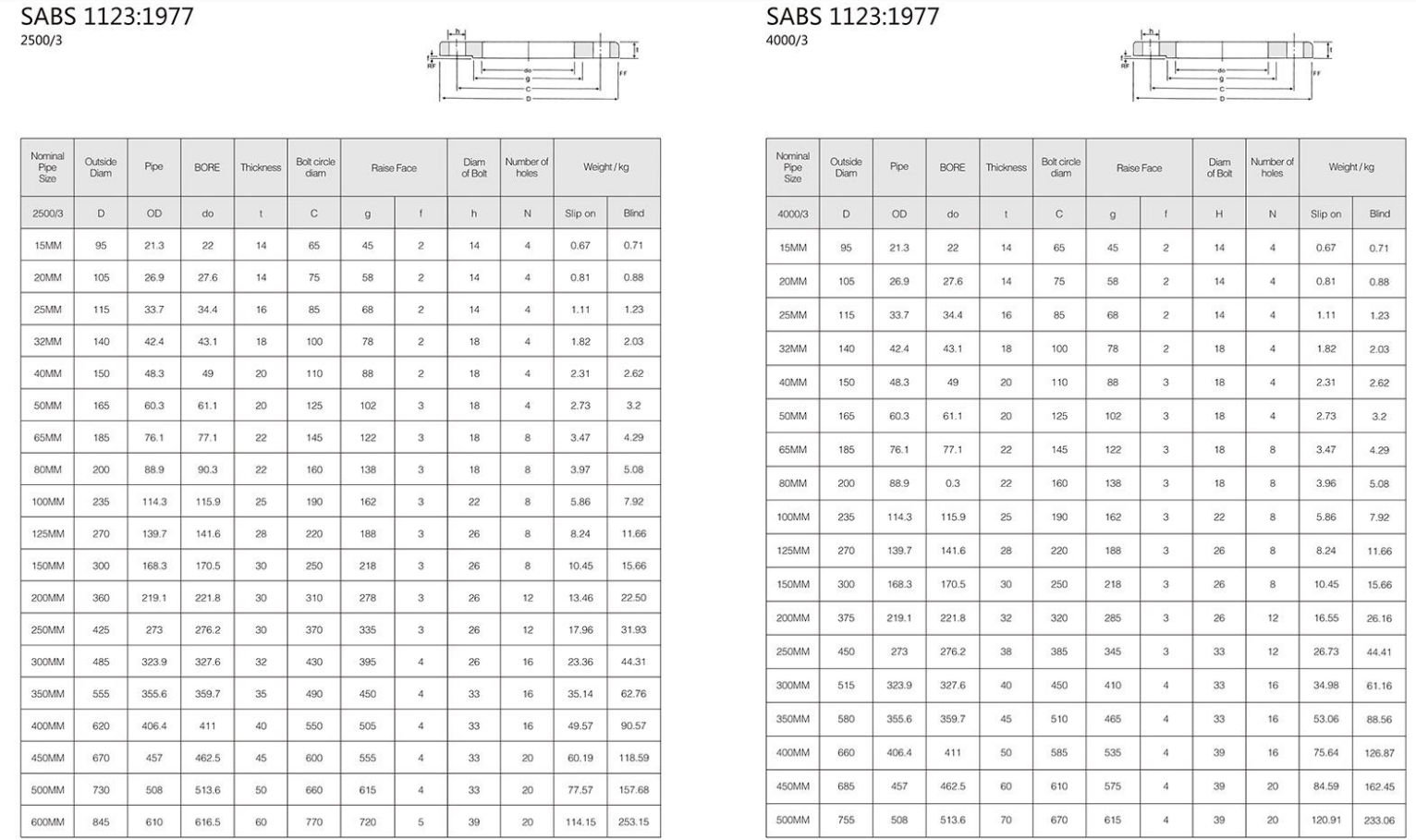

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024