-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Feb . 13, 2025 11:37 Back to list

2 x 12 galvanized pipe

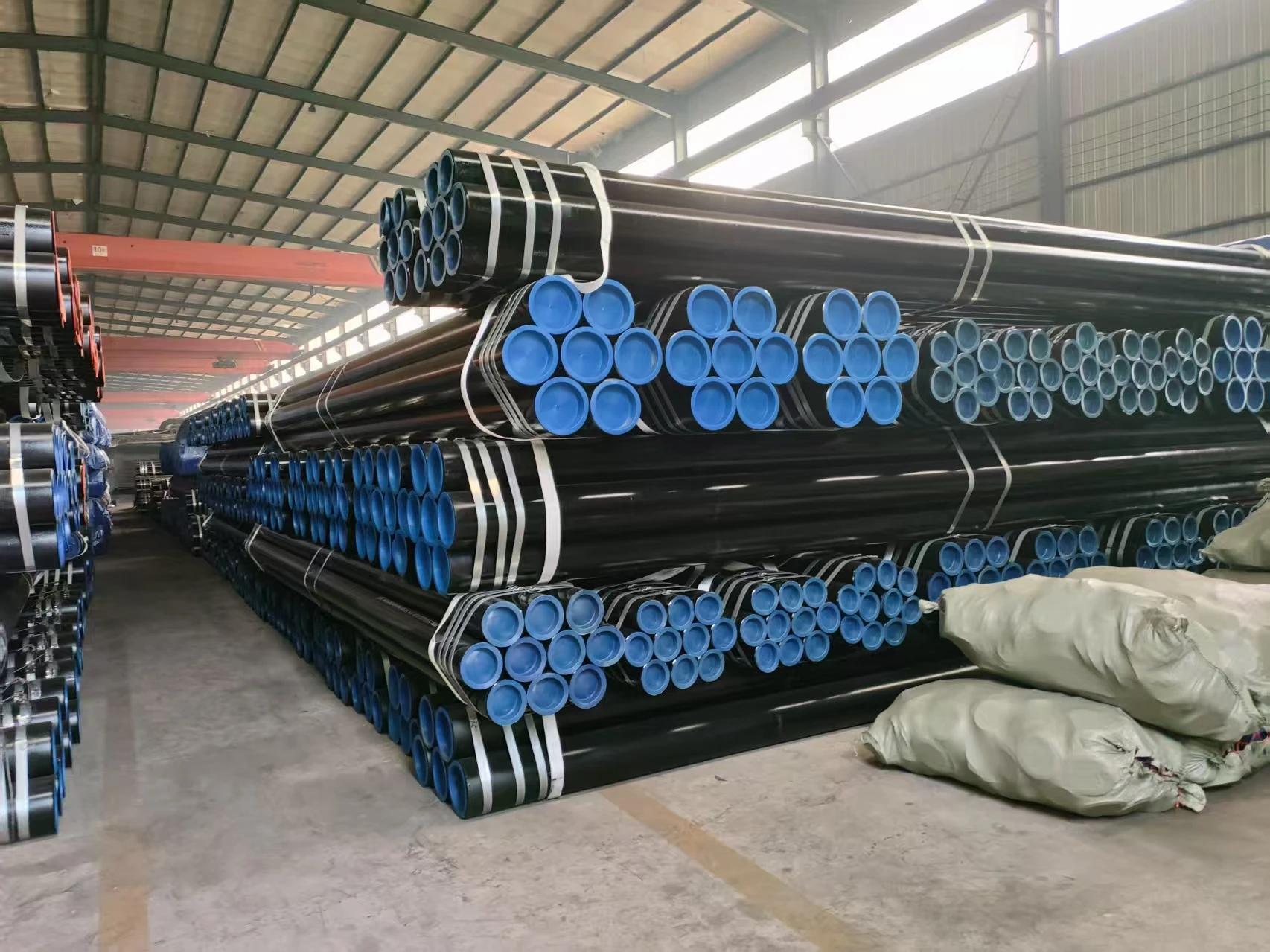

When choosing piping solutions for various construction, plumbing, and industrial applications, it's crucial to prioritize materials that ensure durability, strength, and reliability. This is where the 2 x 12 galvanized pipe stands out, offering a combination of resilience and versatility. Understanding its benefits and applications can significantly enhance the performance and lifespan of any project.

Expert Recommendations for Installation When installing galvanized pipes, it's essential to follow best practices to ensure optimal performance and durability. Experts advise carefully inspecting each pipe section for any signs of damage or imperfections in the zinc coating, which, if left unchecked, could become weak points subject to corrosion. Proper threading techniques must also be employed to prevent leaks and ensure a snug fit with compatible components. Additionally, painting or coating the galvanized pipe post-installation can offer extra protection, particularly in environments with extreme conditions. Some professionals also recommend regular maintenance inspections to catch any potential issues early, extending the lifespan of the piping system. Sustainability Considerations In today's environmentally conscious world, the sustainability of building materials is a critical factor. Galvanized steel pipes, including the 2 x 12 options, are environmentally friendly due to their recyclability. Once they reach the end of their useful life in a project, these pipes can be recycled and repurposed, reducing the environmental footprint and conserving resources. Trust in Quality Assurance Quality assurance is vital when selecting 2 x 12 galvanized pipes. Reputable manufacturers adhere to strict standards and regulations, ensuring each pipe meets industry benchmarks for strength, durability, and safety. Sourcing pipes from trusted suppliers who provide certification and guarantees can foster trust and reliability in any project, reinforcing the choice to use galvanized pipes as a sound investment. Conclusion The 2 x 12 galvanized pipe emerges as a versatile and reliable component for various applications, from construction to industrial use. With its protective galvanization, superior strength, and environmentally friendly profile, it represents a balanced blend of performance and sustainability. By adhering to expert recommendations for installation and maintenance, and choosing quality-assured products, builders and engineers can ensure the longevity and success of their projects with galvanized piping solutions.

Expert Recommendations for Installation When installing galvanized pipes, it's essential to follow best practices to ensure optimal performance and durability. Experts advise carefully inspecting each pipe section for any signs of damage or imperfections in the zinc coating, which, if left unchecked, could become weak points subject to corrosion. Proper threading techniques must also be employed to prevent leaks and ensure a snug fit with compatible components. Additionally, painting or coating the galvanized pipe post-installation can offer extra protection, particularly in environments with extreme conditions. Some professionals also recommend regular maintenance inspections to catch any potential issues early, extending the lifespan of the piping system. Sustainability Considerations In today's environmentally conscious world, the sustainability of building materials is a critical factor. Galvanized steel pipes, including the 2 x 12 options, are environmentally friendly due to their recyclability. Once they reach the end of their useful life in a project, these pipes can be recycled and repurposed, reducing the environmental footprint and conserving resources. Trust in Quality Assurance Quality assurance is vital when selecting 2 x 12 galvanized pipes. Reputable manufacturers adhere to strict standards and regulations, ensuring each pipe meets industry benchmarks for strength, durability, and safety. Sourcing pipes from trusted suppliers who provide certification and guarantees can foster trust and reliability in any project, reinforcing the choice to use galvanized pipes as a sound investment. Conclusion The 2 x 12 galvanized pipe emerges as a versatile and reliable component for various applications, from construction to industrial use. With its protective galvanization, superior strength, and environmentally friendly profile, it represents a balanced blend of performance and sustainability. By adhering to expert recommendations for installation and maintenance, and choosing quality-assured products, builders and engineers can ensure the longevity and success of their projects with galvanized piping solutions.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024