-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 09, 2024 17:15 Back to list

3 8 galvanized pipe

Understanding 3 8% Galvanized Pipe An Overview

Galvanized pipes have become an essential component in various industries, primarily due to their durability and resistance to corrosion. Among the specifications of galvanized pipes, the term 3 8% galvanized pipe often draws attention for its unique properties and applications. Understanding what this designation means can help professionals in construction, plumbing, and other fields make informed decisions based on the specific needs of their projects.

Understanding 3 8% Galvanized Pipe An Overview

One crucial aspect of galvanized pipes is their ability to withstand harsh environmental conditions. The zinc coating acts as a sacrificial barrier; even if the coating is scratched, the underlying steel remains protected because the zinc will corrode first. This makes galvanized pipes an excellent choice for outdoor applications, plumbing systems, and structures subject to moisture and humidity.

3 8 galvanized pipe

The 3% in 3 8% may denote the percentage of zinc used in the coating process. While most galvanized pipes feature a zinc coating of about 1-2%, a 3% coating could imply enhanced protection, making these pipes suitable for even more corrosive environments. This added layer of safety is particularly beneficial in industries like agriculture, wastewater management, and construction, where exposure to elements is inevitable.

The specification 208% likely pertains to the pipe's size and pressure rating. For many applications, particularly in plumbing and drainage systems, the ability to handle high pressure is crucial. A pipe that can maintain structural integrity under significant stress ensures that systems remain functional and safe. Therefore, the 208% could indicate the pipe’s ability to withstand elevated pressure levels, making it suitable for more demanding applications.

Galvanized pipes are not only durable but are also relatively easy to install and maintain. As they come pre-coated, there is usually less need for additional protective finishes, saving time and costs during installation. Moreover, their smooth surface allows for efficient flow of liquids, making them a preferred choice for both drinking water and wastewater systems.

In conclusion, the 3 8% galvanized pipe represents a significant advancement in piping technology. With improved corrosion resistance due to a higher zinc coating and enhanced pressure ratings, these pipes are designed to meet the growing demands across various industries. As construction and plumbing continue to evolve, the reliance on durable, efficient materials like the 3 8% galvanized pipe will undoubtedly increase, ensuring that infrastructure remains robust and reliable for years to come. Whether you are a contractor, engineer, or DIY enthusiast, understanding the benefits and specifications of these pipes is essential for successful project implementation.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

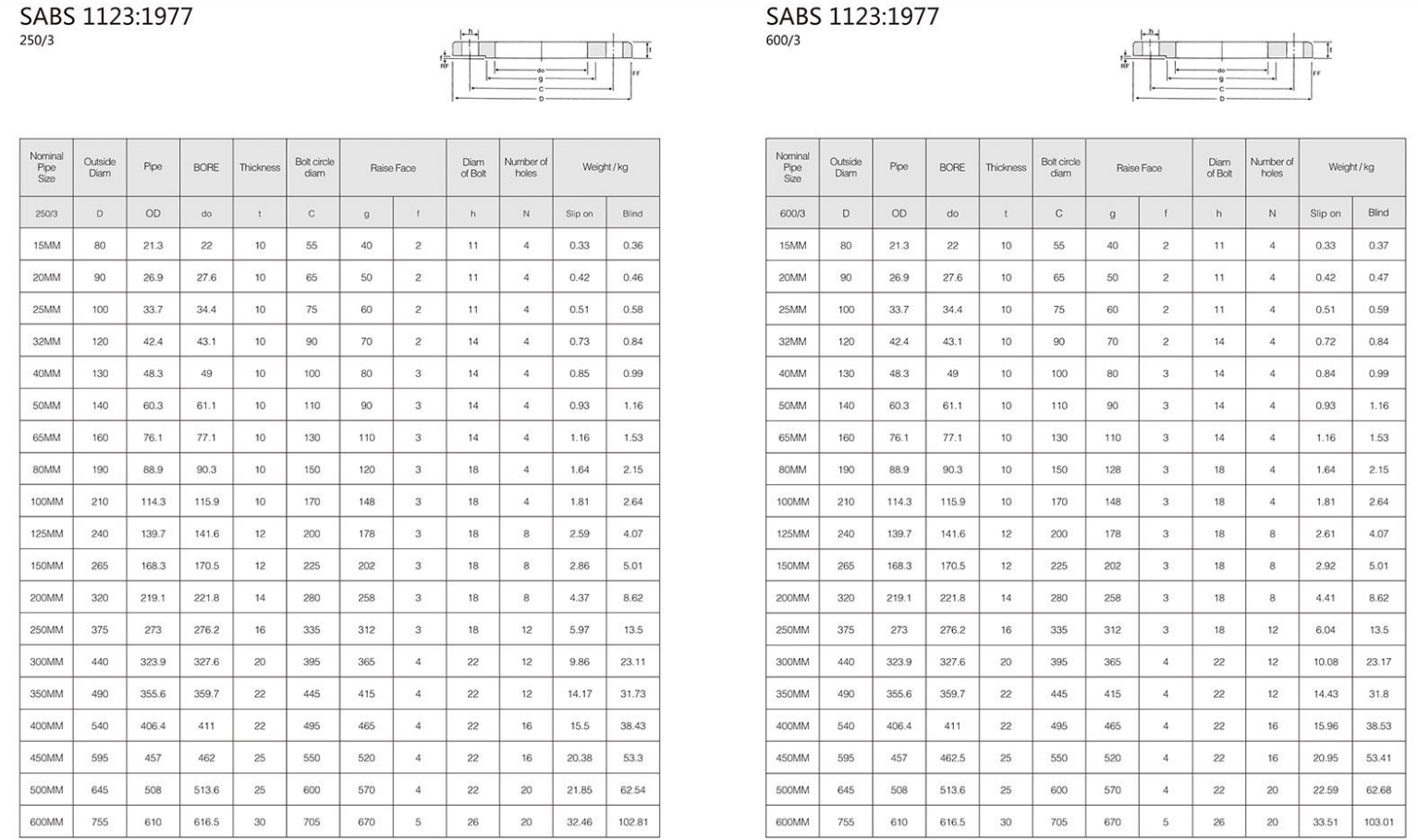

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024