-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 22, 2024 12:31 Back to list

304 stainless steel socket weld fittings

Understanding 304 Stainless Steel Socket Weld Fittings

Stainless steel socket weld fittings are critical components in many industries, particularly those that operate under high pressure and temperature conditions. Among the various grades of stainless steel available, 304 stainless steel fittings are widely recognized for their durability, resistance to corrosion, and overall performance. In this article, we will delve into the characteristics, advantages, applications, and maintenance of 304 stainless steel socket weld fittings, highlighting their importance in industrial applications.

Characteristics of 304 Stainless Steel Socket Weld Fittings

304 stainless steel is an austenitic stainless steel that contains a minimum of 18% chromium and 8% nickel. This composition provides excellent corrosion resistance and allows these fittings to maintain their strength at elevated temperatures. Socket weld fittings, which are designed to connect pipes, are typically welded to the pipe's surface to create a secure joint. This type of fitting is commonly used in applications where high-pressure performance is necessary.

One of the hallmark characteristics of 304 stainless steel is its ability to withstand a wide range of corrosive environments. It is particularly resistant to oxidation and pitting, making it suitable for both indoor and outdoor applications. The low carbon content of 304 stainless steel also helps to minimize the risk of carbide precipitation during welding, ensuring a strong and durable weld.

Advantages of Using 304 Stainless Steel Socket Weld Fittings

Using 304 stainless steel socket weld fittings offers several advantages. Firstly, their corrosion resistance means longer service life and reduced maintenance costs in environments where traditional steel fittings would quickly deteriorate. Secondly, these fittings can withstand extreme temperatures, which is crucial in many industries such as oil and gas, chemical processing, and power generation.

Another significant advantage is the ease of installation

. Socket weld fittings allow for precise alignment and a tight fit, which contributes to leak-free connections. The design helps in avoiding the need for extensive threading, minimizing the time and effort required for installation.Moreover, 304 stainless steel is versatile and can be easily integrated into various piping systems. Its mechanical properties, such as tensile strength and ductility, make it suitable for a range of applications, from plumbing and HVAC systems to industrial machinery.

Applications of 304 Stainless Steel Socket Weld Fittings

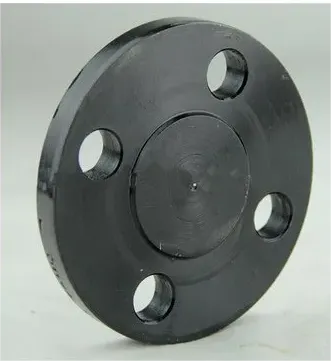

304 stainless steel socket weld fittings

The applications of 304 stainless steel socket weld fittings are numerous. They are extensively used in industries such as

1. Oil and Gas Used in refineries and wellhead systems where high pressure and corrosive environments are prevalent. 2. Chemical Processing Employed in the manufacturing processes where resistance to harsh chemicals is necessary. 3. Food and Beverage Ensures hygienic conditions in processing and transporting consumables, as stainless steel does not react with food products.

4. Pharmaceuticals Used in systems requiring high cleanliness standards and resistance to contaminants.

5. Power Generation Utilized in piping systems that transport steam and other fluids under high pressure and temperature.

Maintenance Tips for 304 Stainless Steel Socket Weld Fittings

To ensure the longevity and efficiency of 304 stainless steel socket weld fittings, regular maintenance is crucial. Here are a few tips

- Routine Inspection Check for signs of wear, corrosion, or any leaks during regular maintenance checks. - Clean Regularly Remove any contaminants that could promote corrosion. Use non-abrasive cleaners to prevent scratches on the surface. - Proper Handling During installation and maintenance, handle fittings carefully to avoid damaging any integral components.

Conclusion

In summary, 304 stainless steel socket weld fittings play a vital role in numerous industrial applications due to their strength, corrosion resistance, and ease of installation. As industries continue to advance and face new challenges, these fittings are likely to remain a preferred choice for professionals seeking reliable and effective piping solutions. Whether in the oil and gas sector, chemical processing, or food and beverage industries, the applicability and dependability of 304 stainless steel socket weld fittings cannot be understated.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024

-

DIN2605-2617 Butt-Welding Fittings LR/SR 45°/90°/180° Seamless/Weld

NewsApr.23,2024