-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 07, 2024 02:35 Back to list

304 Stainless Steel Tube Suppliers for Your Industrial Needs and Applications

The Pros and Cons of Sourcing 304 Stainless Steel Tubing A Guide for Buyers

When it comes to selecting materials for construction, manufacturing, or a variety of engineering applications, 304 stainless steel tubing is a popular choice. Known for its excellent corrosion resistance, durability, and versatility, 304 stainless steel is commonly used in various sectors, including automotive, aerospace, food processing, and pharmaceuticals. However, sourcing 304 stainless steel tubing from suppliers requires careful consideration of various factors. In this article, we will explore the benefits and challenges of sourcing this material and provide insights into finding reputable suppliers.

What is 304 Stainless Steel?

304 stainless steel is an austenitic alloy composed primarily of iron, chromium, and nickel. It typically contains 18% chromium and 8% nickel, giving it a unique combination of strength, ductility, and corrosion resistance. This alloy is non-magnetic and can be easily welded and formed, making it highly desirable for a range of applications.

Advantages of 304 Stainless Steel Tubing

1. Corrosion Resistance One of the main reasons for choosing 304 stainless steel tubing is its impressive resistance to corrosion. The alloy's chromium content forms a passive layer of chromium oxide on the surface, which protects it from oxidation and rust.

2. High Strength and Durability The strength of 304 stainless steel ensures that it can withstand high pressure and temperature conditions, making it ideal for use in harsh environments.

3. Versatile Applications 304 stainless steel tubing is used in various applications, such as heat exchangers, food and beverage processing equipment, and architectural structures. Its adaptability makes it suitable for both industrial and residential projects.

4. Aesthetic Appeal The shiny, polished finish of 304 stainless steel provides a modern look, making it a popular choice for decorative applications.

5. Ease of Fabrication This material can be cut, welded, and formed with relative ease, which can lead to reduced labor costs and faster project completion times.

Challenges in Sourcing 304 Stainless Steel Tubing

1. Quality Assurance Not all suppliers offer the same quality of 304 stainless steel tubing. It’s essential to check certifications and ensure that the material meets industry standards, such as ASTM A213 or ASME SA213.

304 stainless steel tubing suppliers

2. Price Fluctuations The price of stainless steel is influenced by global market trends. Supplies can experience fluctuations in prices due to factors such as raw material costs, geopolitical issues, and changes in demand.

3. Supply Chain Issues Ensuring a steady supply of 304 stainless steel tubing can be challenging, especially during periods of high demand or disruptions, such as those caused by pandemics or natural disasters.

4. Supplier Reliability Choosing a dependable supplier is crucial. The quality of workmanship and the reliability of delivery schedules can significantly impact project timelines and budgets.

Choosing the Right Supplier

When looking for suppliers of 304 stainless steel tubing, consider the following

1. Reputation Research suppliers’ reputations through customer reviews and industry feedback. A company with a strong track record is more likely to provide high-quality products and services.

2. Certifications Ensure that potential suppliers adhere to relevant industry standards and possess the necessary certifications. This could include ISO certifications or specific material certifications.

3. Inventory Opt for suppliers that maintain a substantial inventory, as this reduces lead times and ensures you can acquire the required quantities without delays.

4. Customer Service Evaluate the level of customer service offered by potential suppliers. Responsive and knowledgeable support can make a significant difference during the sourcing process.

5. Pricing and Payment Terms While price is a critical factor, it should not be the only consideration. Look for suppliers that offer competitive pricing alongside favorable payment terms.

Conclusion

Sourcing 304 stainless steel tubing involves careful consideration of many factors, including quality assurance, pricing, and supplier reliability. By understanding the advantages and potential challenges associated with this material, buyers can make informed decisions to ensure successful project outcomes. In a competitive market, the right supplier can provide quality products that meet your specifications and deadlines, making it a top priority when planning your next project.

Latest news

-

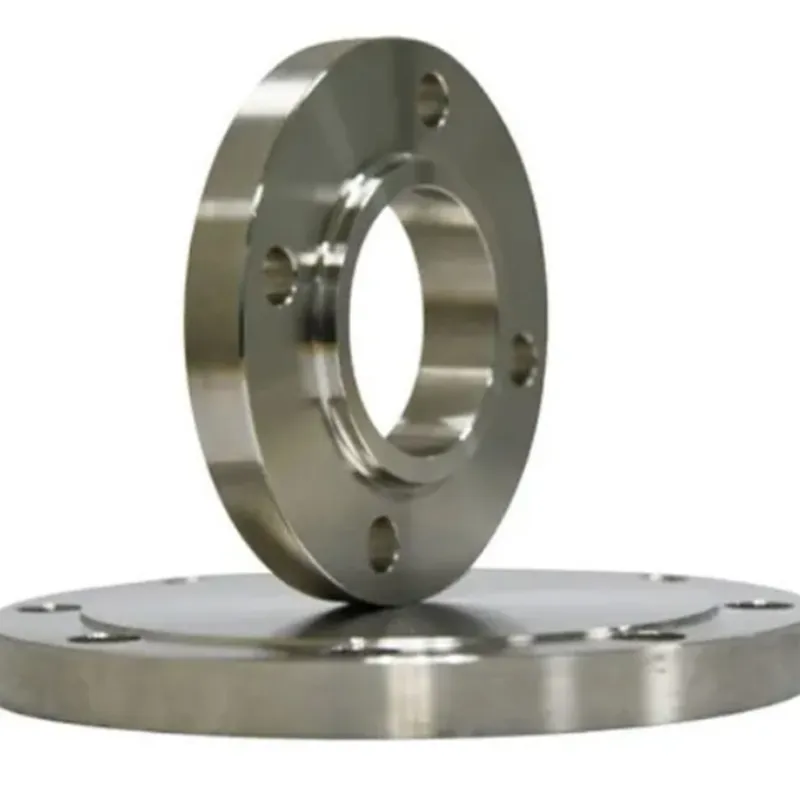

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024