-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 20, 2024 04:45 Back to list

3 ansi 150 flange

Understanding the 3% ANSI 150 Flange An Overview

In the world of piping systems and industrial applications, flanges play a crucial role in connecting two sections of pipe, providing ease of assembly and disassembly for maintenance and repairs. Among the various types of flanges available in the market, the ANSI 150 flange, particularly with a 3% rating, stands out due to its standardized design and widespread application. This article aims to explore the characteristics, applications, and benefits of the 3% ANSI 150 flange.

What is ANSI 150 Flange?

The American National Standards Institute (ANSI) developed a series of standards that specify the design and dimensional characteristics of different types of flanges. The ANSI 150 flange refers to a class rating that defines the maximum pressure-temperature ratings for flanges. The 150 essentially indicates a maximum pressure of 150 pounds per square inch (psi) at room temperature, which can vary with temperature changes.

The 3% designation typically refers to the maximum allowable deviation in dimensions (such as thickness and diameter) from the nominal size specified for the flange. This tolerance ensures that the flange will fit properly with corresponding components, ensuring a secure and leak-free connection.

Characteristics of ANSI 150 Flanges

1. Material Composition ANSI 150 flanges can be manufactured from various materials, including carbon steel, stainless steel, and alloys. The choice of material significantly impacts the flange's durability, corrosion resistance, and overall performance in specific environments.

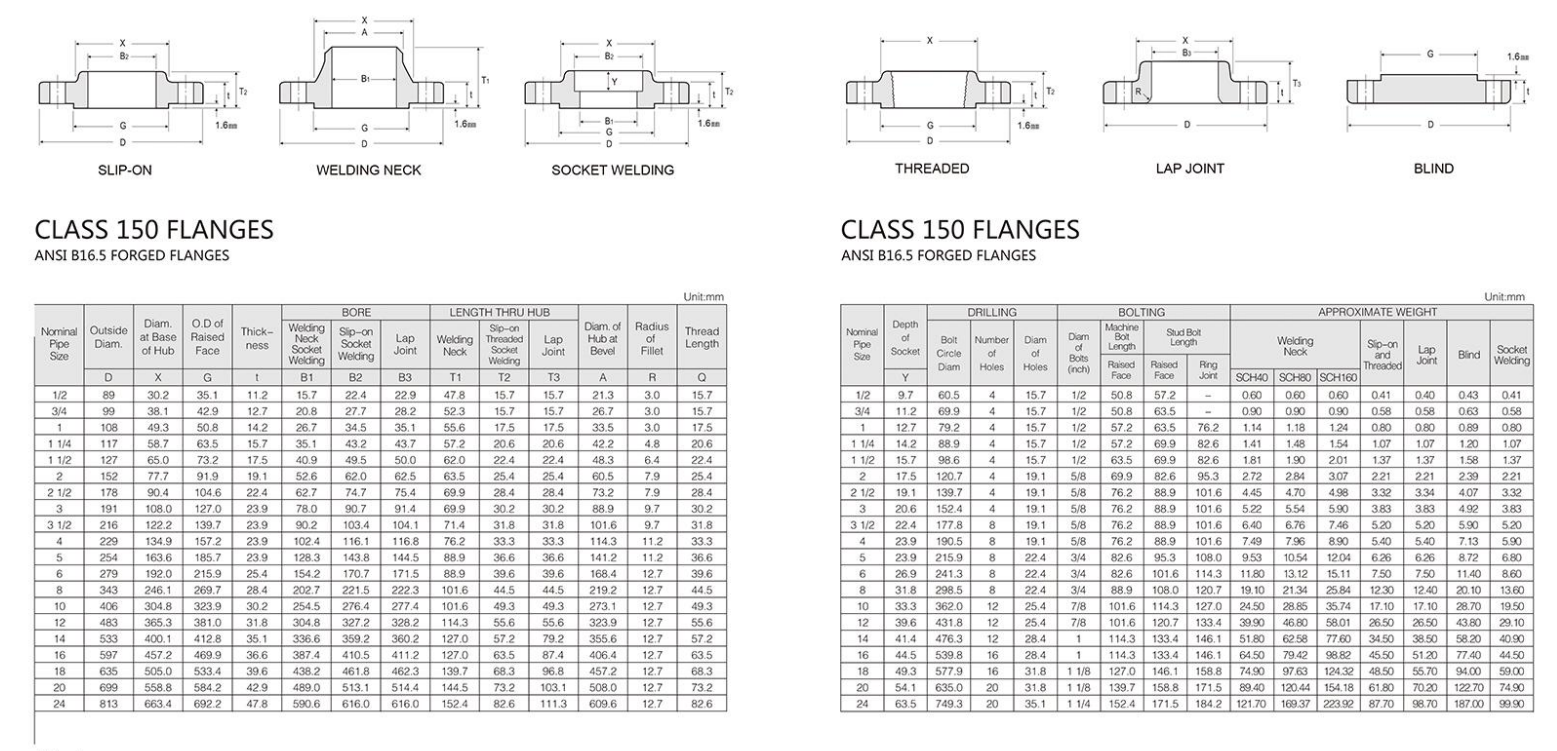

2. Dimensions and Compatibility ANSI 150 flanges adhere to standardized dimensions outlined in the ANSI/ASME B16.5 standard. This ensures compatibility with other piping components, making them easily interchangeable in industrial applications.

3. Design The ANSI 150 flange is typically a flat type of flange, featuring a raised face (RF) design, which aids in achieving better sealing against the gasket when tightened. The dimensions, as defined by the ANSI standard, allow for various bolt patterns, making it easier to connect with other flanges.

Applications of ANSI 150 Flanges

3 ansi 150 flange

The versatility and reliability of ANSI 150 flanges make them suitable for a wide range of applications across different industries

. Some common applications include- Water and Wastewater Management ANSI 150 flanges are extensively used in water treatment plants, sewage systems, and pumping stations. Their robust design allows them to withstand the pressures associated with fluid transport.

- Oil and Gas In the oil and gas sector, ANSI 150 flanges are utilized in pipelines and rigs where pressure and temperature control are critical. Their ability to safely connect various pipeline segments makes them vital in this industry.

- Chemical Processing The chemical industry often employs ANSI 150 flanges to manage the safe transfer of volatile or corrosive substances. The choice of materials, such as stainless steel, provides added corrosion resistance.

Benefits of Using ANSI 150 Flanges

1. Ease of Installation and Maintenance The standardized design of ANSI 150 flanges allows for quick installation and disassembly, facilitating easy maintenance and repairs.

2. Cost-Effectiveness Due to their standardization, ANSI 150 flanges are readily available, making them a cost-effective option for many industrial applications.

3. Safe and Reliable Connection The design and material options offer a safe and reliable connection, minimizing the risk of leaks, which is paramount in high-pressure applications.

Conclusion

The 3% ANSI 150 flange represents a crucial component in various piping applications, offering reliability, versatility, and ease of maintenance. With a structure that adheres to strict standards and tolerances, these flanges ensure that industrial systems operate smoothly. As industries continue to evolve, the demand for durable and effective connections will maintain the relevance of ANSI 150 flanges in modern engineering and construction.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024