-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 22, 2024 06:48 Back to list

3% Stainless Steel Mandrel Bends for Automotive and Industrial Applications

The Significance of 3% Stainless Steel Mandrel Bends in Engineering and Construction

Stainless steel is celebrated for its corrosion resistance, durability, and aesthetic appeal, making it a preferred material in various industries, including construction, automotive, and manufacturing. Among the pivotal components of stainless steel fabrication are mandrel bends, particularly those made from 3% stainless steel alloys, which offer a perfect balance between flexibility and strength.

Understanding Mandrel Bends

Mandrel bends are used to create smooth, uniform curves in piping and tubing. Unlike traditional bending methods, which can lead to deformation and harsh kinks, mandrel bending utilizes a specialized tool, known as a mandrel, to support the material during the bending process. This ensures that the internal diameter remains consistent, preventing any loss in flow efficiency or structural integrity. The result is a high-quality bend that maintains the original cross-sectional area of the tube or pipe.

Advantages of 3% Stainless Steel

The term “3% stainless steel” typically refers to a specific alloy blend that includes chromium, nickel, and molybdenum, providing superior resistance to corrosion and high temperatures. This composition not only enhances durability but also improves the material’s ability to withstand harsh environmental conditions and stress. Additionally, 3% stainless steel is known for its excellent weldability, making it a desirable choice for applications where structural integrity is paramount.

1. Corrosion Resistance 3% stainless steel boasts an impressive resistance to oxidizing agents, ensuring longevity in applications exposed to moisture, chemicals, and various corrosive environments. 2. Strength and Durability With a higher tensile strength compared to standard steel, 3% stainless steel is capable of supporting more significant loads without bending or breaking.

3. Aesthetic Appeal The sleek, polished finish of stainless steel gives it a modern look, making it a popular choice for architectural applications where visual appeal is important.

3 stainless steel mandrel bends

Applications of 3% Stainless Steel Mandrel Bends

Mandrel bends made from 3% stainless steel are utilized in diverse applications, demonstrating their versatility and reliability

. Some prominent uses include- Automotive Industry In the automotive sector, mandrel bends are essential for exhaust systems and fuel lines, where maintaining consistent flow is crucial. The use of 3% stainless steel ensures resistance to heat and corrosion from various exhaust gases.

- Piping Systems In industrial piping systems, mandrel bends help navigate complex configurations while maintaining flow efficiency. The durability of 3% stainless steel ensures that these systems can operate under high pressure and temperature conditions.

- Architectural Features Stainless steel mandrel bends can also be found in architectural designs, such as railings and decorative elements, where both strength and elegance are desired.

- Food and Beverage Industry The hygiene standards in the food and beverage industry require materials that are easy to clean and resistant to bacteria. 3% stainless steel meets these requirements, making it ideal for processing equipment.

Conclusion

In conclusion, 3% stainless steel mandrel bends represent an intersection of engineering excellence and material innovation. Their unique properties not only enhance the structural efficiency and aesthetic value of various applications but also ensure their resilience under challenging conditions. As industries continue to evolve, the demand for high-quality fittings like these will only grow, highlighting the importance of utilizing advanced materials in design and construction. By prioritizing durability, versatility, and performance, 3% stainless steel mandrel bends will undeniably play a crucial role in shaping the future of engineering and manufacturing.

Latest news

-

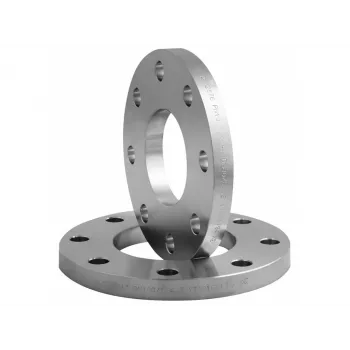

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024